New multi-line composited thread-form thread

A thread and thread technology, applied in the field of multi-thread compound thread type new thread, can solve the problems of reduced transmission accuracy, small size, uneven force on thread teeth, etc., to achieve improved connection strength and transmission accuracy, strong bearing capacity, Choose from a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

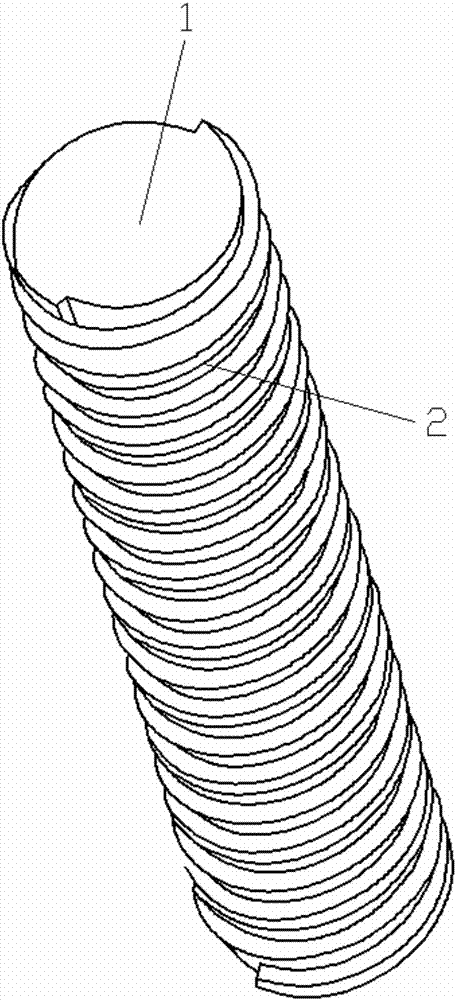

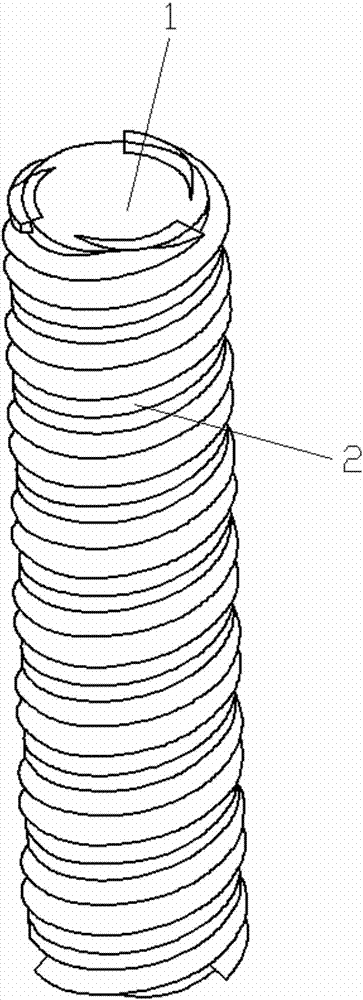

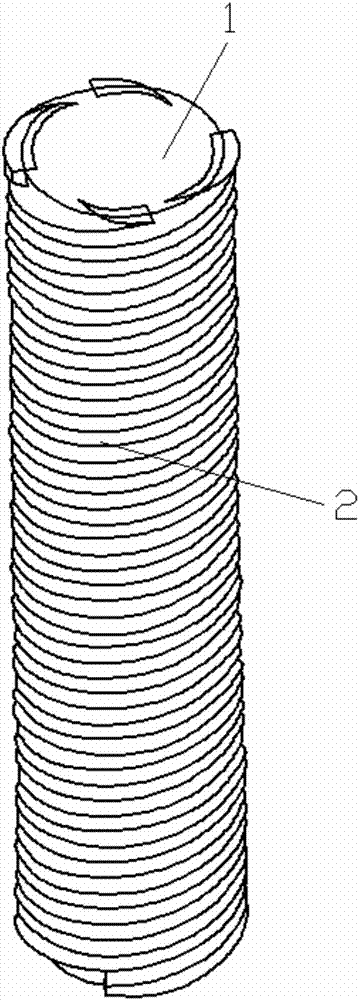

[0013] Attached below figure 1 A first embodiment of the present invention will be described.

[0014] The multi-thread compound tooth type new thread has a body 1, and the axial outer peripheral wall of the body 1 is processed with a plurality of threads 2 formed by equidistantly distributed helical lines, and the thread 2 tooth type formed by each helical line Not all the same, after the body 1 is screwed with the helix of the body 1 and the matching parts that match the tooth shape, the connection strength or transmission accuracy of the body 1 and the matching parts can be improved; specifically, the tooth type of the thread 2 Triangular, rectangular or trapezoidal, the number of helixes of the thread 2 on the body 1 is 2, and the types of threads 2 of the thread 2 are 2 types, which are staggered and equidistantly distributed on the body 1 . This embodiment is a new type of thread with two-line composite tooth type. The two helical lines are evenly distributed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com