Plate heat exchanger unit and connecting structure

A plate heat exchanger and plate technology, applied in the direction of heat exchanger types, indirect heat exchangers, laminated elements, etc., can solve the problems that hinder the industrial application process of high temperature heat pipe heat exchangers, and the unreasonable and abnormal connection of transition sections. Work status and other issues, to achieve the effect of rich connection forms, low production equipment requirements, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

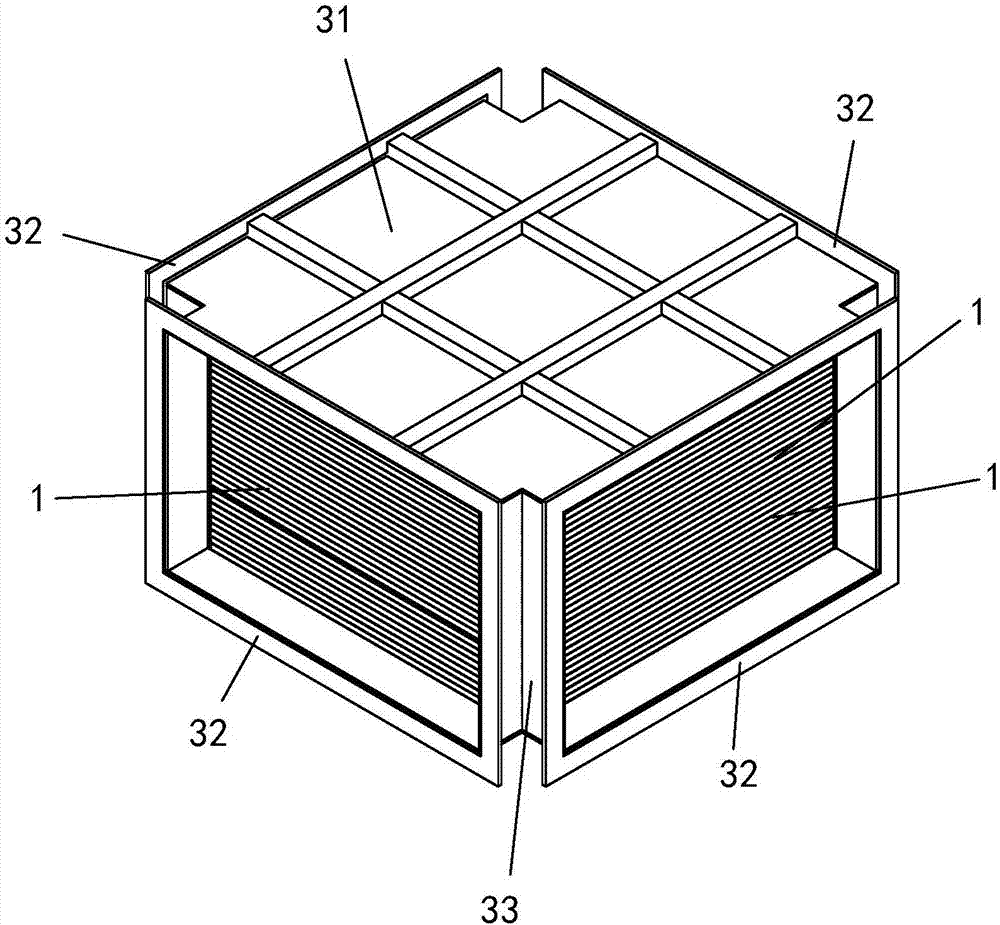

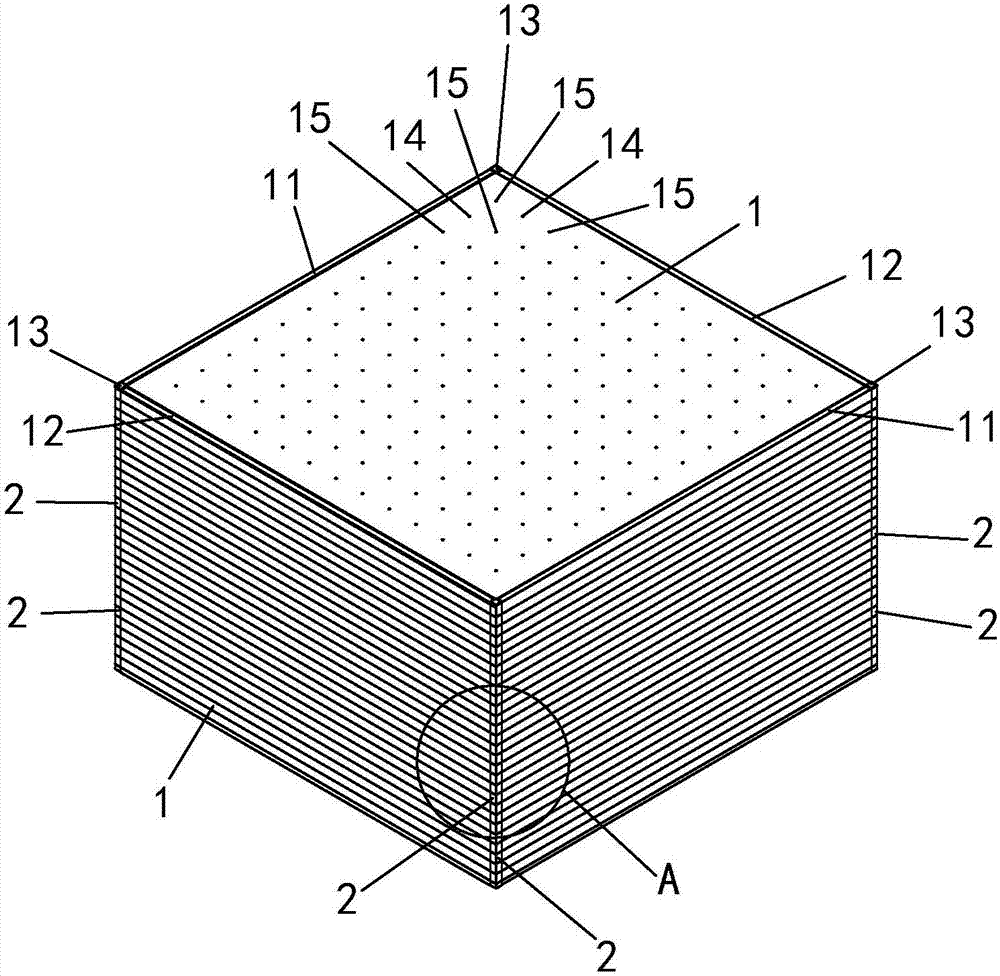

[0066] See attached Figure 1~Figure 17 As shown, a plate heat exchanger unit includes a core body and an outer frame, and the core body is accommodated in the outer frame, wherein:

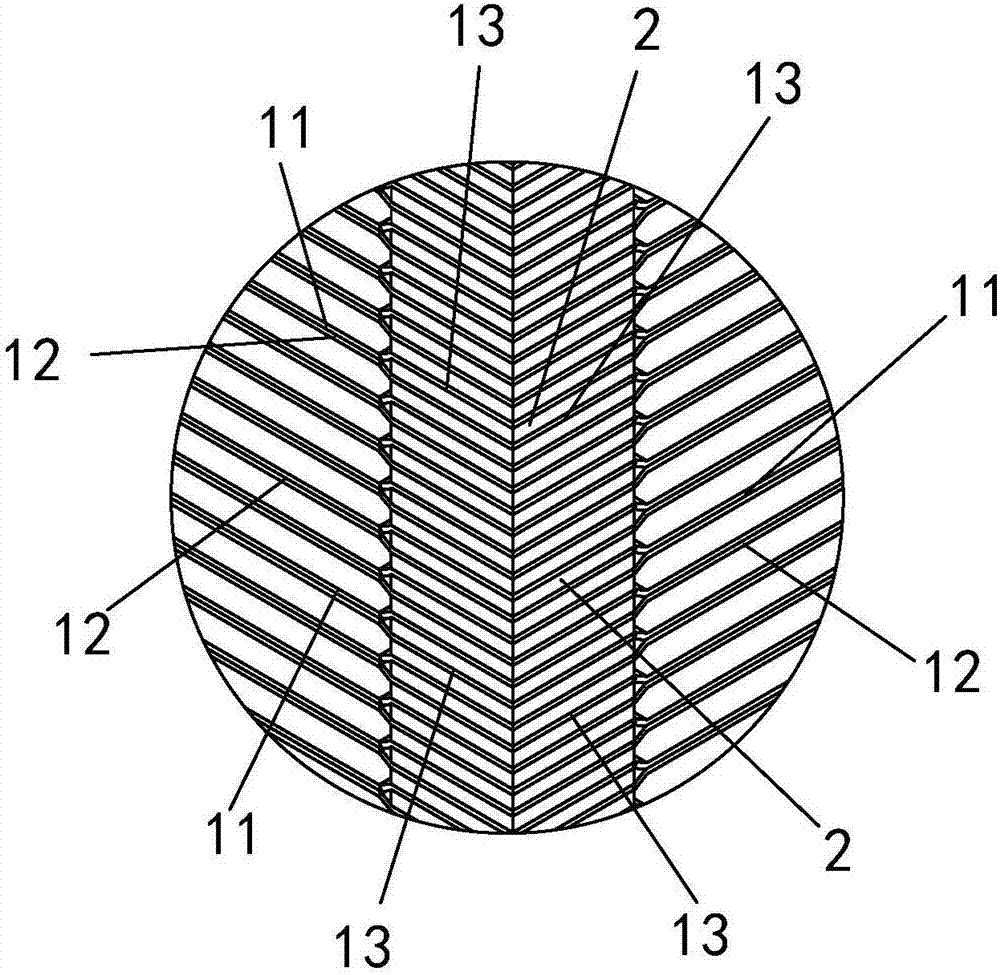

[0067] It includes several plates 1, and each plate 1 is stacked in its thickness direction.

[0068] The main body of the plate 1 is a square metal plate, the two surfaces of the square metal plate are respectively defined as the front and the back, and the four sides of the square metal plate are defined as the first side, the second side in the clockwise direction or the counterclockwise direction. Second side, third side and fourth side.

[0069] The edges of the first side and the third side are provided with a first folding bar 11 towards the front side of the square metal plate; There is a second folding bar 12.

[0070] There is a transition plate 13 at the junction of each adjacent first folded strip 11 and second folded strip 12, and the transition plate 13 is located on the same pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com