Positive electrode material and preparation method thereof

A positive electrode material, lithium manganese chromium technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problem of no obvious improvement in the rate performance of layered oxide positive electrode materials, to reduce production costs, save energy, and sintering temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

[0028] Li 1.2 Mn 0.6 Cr 0.2 O z / graphene cathode material, namely x=0.62, y=0.08, wherein the mass ratio of lithium manganese chromium oxide and graphene is 100:1.

[0029] Using lithium carbonate, manganese acetate, chromium acetate and graphene oxide as starting materials, 1.471g manganese acetate and 0.458g chromium acetate were dissolved in 30mL H 2 Mixed solution of O and 20 mL of absolute ethanol; ultrasonically dispersed graphene oxide into it; dissolve 0.466 g of lithium carbonate in 100 mL of H 2 Evaporate the obtained solution to dryness at 140 °C and then dry it at 200 °C for 10 h; put the dried precursor into the crucible, and heat it up to 1 °C / min in a box furnace Heating at 400°C for 3h; finally transferred to a tube furnace and heat-treated at 700°C for 12h under the protection of Ar, and Li can be obtained after cooling with the furnace 1.2 Mn 0.6 Cr 0.2 O z / Graphene cathode material.

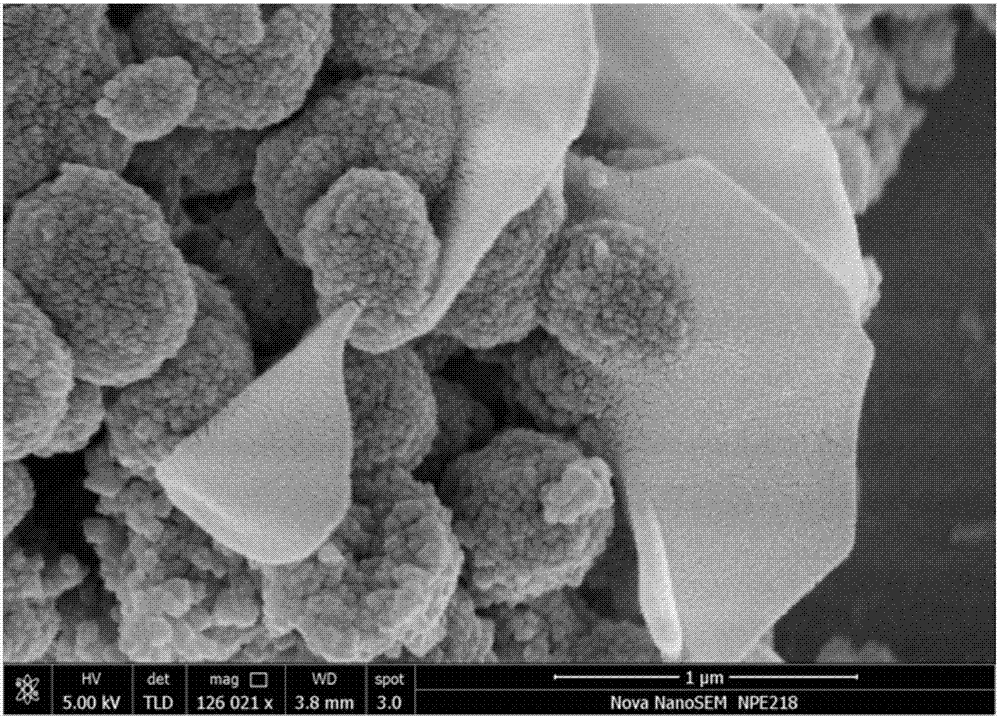

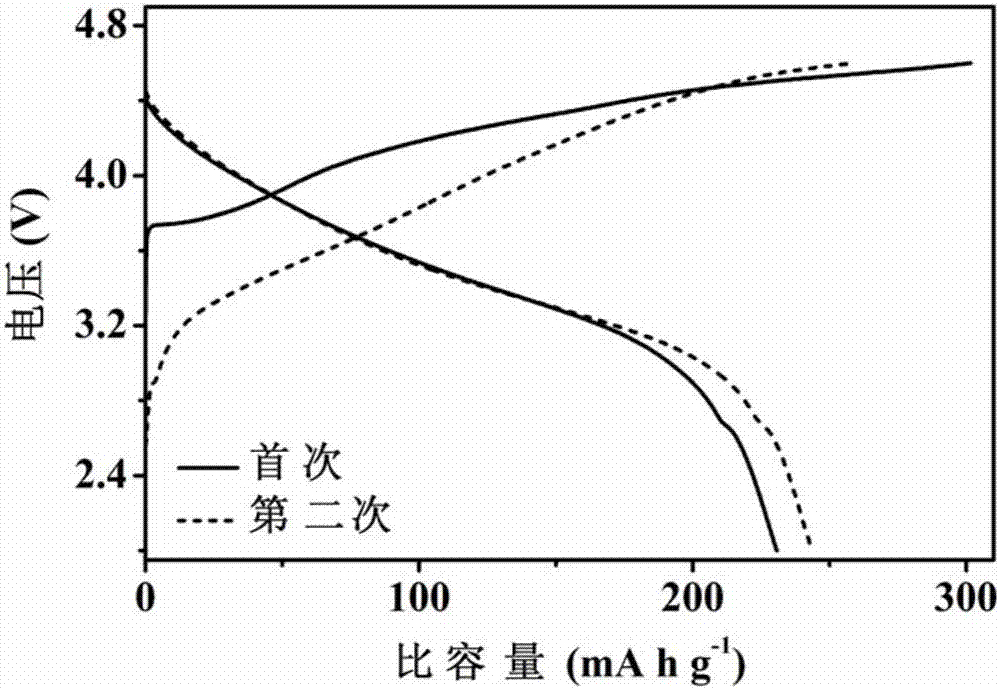

[0030] The above Li 1.2 Mn 0.6 Cr 0.2 O...

Example Embodiment

[0031] Example 2

[0032] Li 1.2 Mn 0.5 Cr 0.3 O z / Graphene cathode material, namely x=0.53, y=0.02, wherein the mass ratio of lithium manganese chromium oxide and graphene is 100:1.

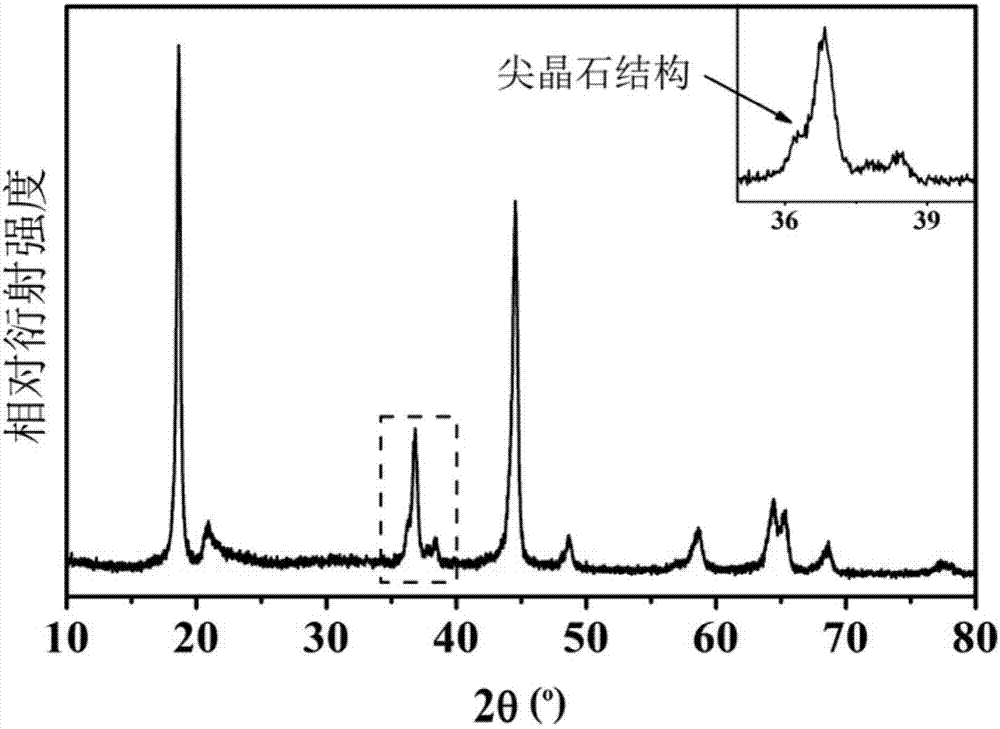

[0033] Using lithium carbonate, manganese acetate, chromium acetate and graphene oxide as starting materials, 1.226g manganese acetate and 0.687g chromium acetate were dissolved in 30mL H 2 Mixed solution of O and 20 mL of absolute ethanol; ultrasonically dispersed graphene oxide into it; dissolve 0.466 g of lithium carbonate in 100 mL of H 2Evaporate the obtained solution to dryness at 140 °C and then dry it at 200 °C for 10 h; put the dried precursor into the crucible, and heat it up to 1 °C / min in a box furnace Heating at 400°C for 3h; finally transferred to a tube furnace and heat-treated at 700°C for 12h under the protection of Ar, and Li can be obtained after cooling with the furnace 1.2 Mn 0.5 Cr 0.3 O z / Graphene cathode material. The XRD test results of the material show tha...

Example Embodiment

[0034] Example 3: Li 1.3 Mn 0.5 Cr 0.2 O z / Graphene cathode material, namely x=0.872, y=0.008, wherein the mass ratio of lithium manganese chromium oxide and graphene is 100:1.

[0035] Using lithium carbonate, manganese acetate, chromium acetate and graphene oxide as starting materials, 1.226g manganese acetate and 0.458g chromium acetate were dissolved in 30mL H 2 Mixed solution of O and 20 mL of absolute ethanol; ultrasonically dispersed graphene oxide into it; dissolve 0.504 g of lithium carbonate in 100 mL of H 2 Evaporate the obtained solution to dryness at 140 °C and then dry it at 200 °C for 10 h; put the dried precursor into the crucible, and heat it up to 1 °C / min in a box furnace Heating at 400°C for 3h; finally transferred to a tube furnace and heat-treated at 700°C for 12h under the protection of Ar, and Li can be obtained after cooling with the furnace 1.3 Mn 0.5 Cr 0.2 O z / Graphene cathode material. The XRD test results of the material show that the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap