Baking tray assembly and electric oven

A technology for electric ovens and baking pans, applied in the field of electric ovens, can solve the problems of undercooked food, uneven heating of heating pipes, uneven heating of food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

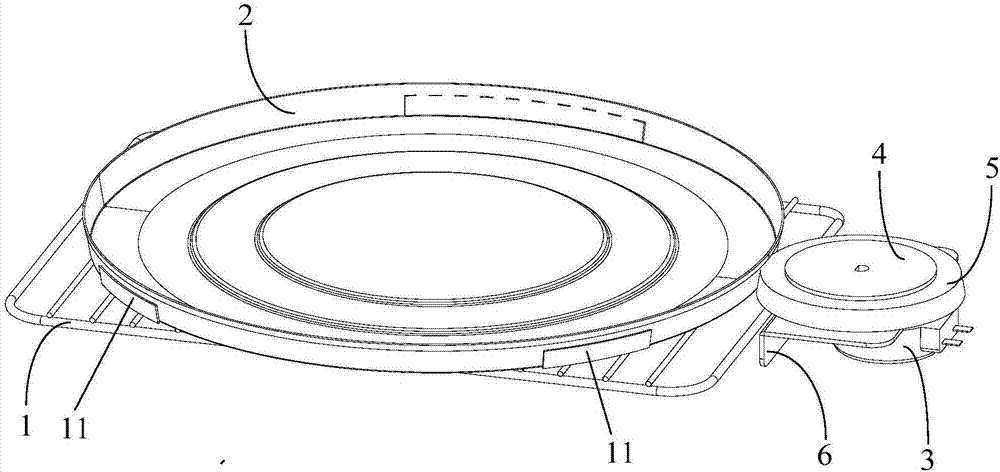

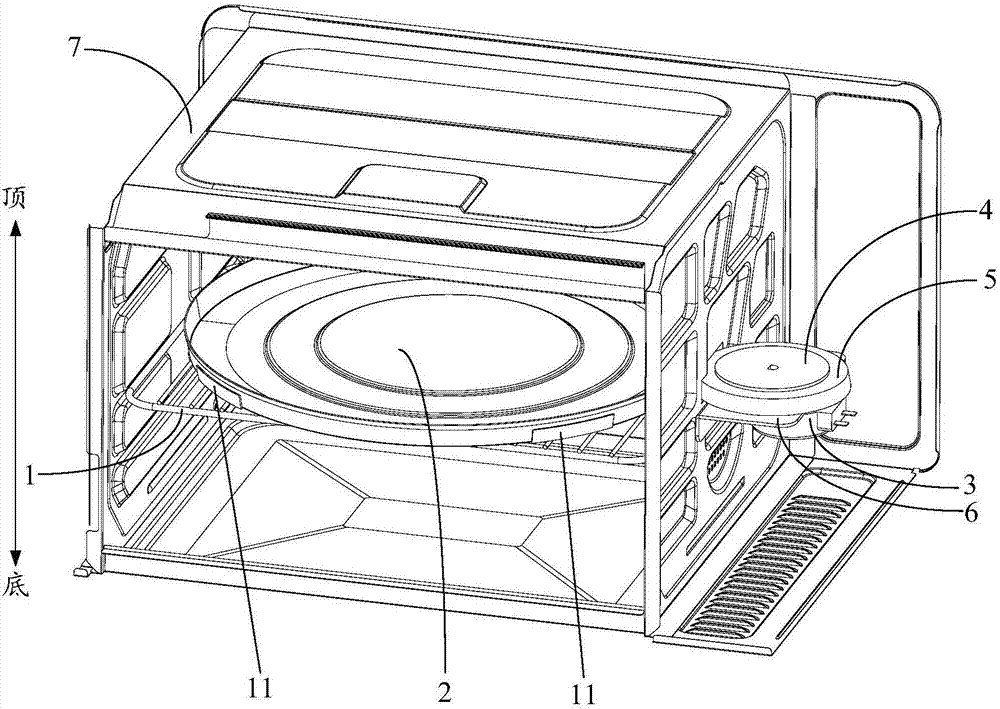

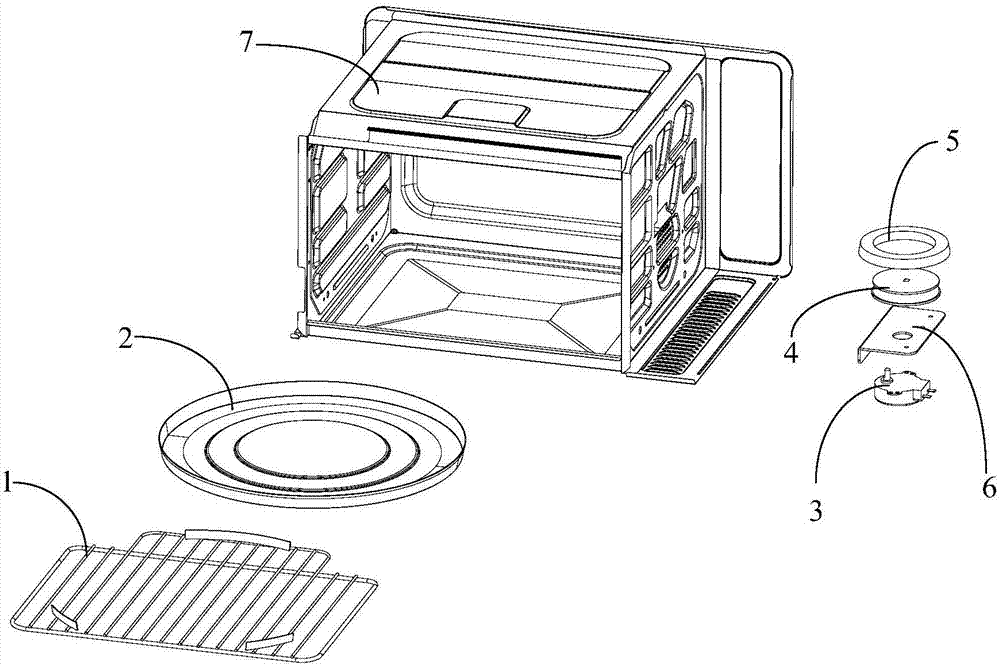

[0038] like Figure 1 to Figure 5 As shown, the grill assembly includes: a grill 1, a grill 2, a motor 3, a transmission shaft and a fixed frame 6, the grill 1 is detachably installed in the cooking cavity 7 of the electric oven, and the grill 1 is provided with a limit The limiting part includes a plurality of arc-shaped limiting ribs 11 located on the same circumference, and the diameter of the circumference where the arc-shaped limiting ribs 11 are located is adapted to the outer diameter of the baking pan 2, so that the baking pan 2 is placed on the grill 1, the grill pan 2 can rotate around its own axis relative to the grill 1, but cannot move horizontally. The fixed frame 6 is fixedly installed on the outer wall of the cooking cavity 7, and the motor 3 is fixedly installed on the fixed frame 6. Cooking The cavity wall of the cavity 7 is provided with a through hole, the transmission shaft is fixedly connected with the motor shaft of the motor 3, and can rotate around its...

Embodiment 2

[0049] The baking pan assembly includes: a grill, a baking pan, a motor, a transmission gear and a fixed frame. The grill is detachably installed in the cooking cavity of the electric oven. There is a limiting part on the grill, and the limiting part includes a A plurality of arc-shaped limiting ribs, and the diameter of the circumference of the arc-shaped fiber ribs is adapted to the outer diameter of the baking pan, so that when the baking pan is placed in the limiting part of the grill, the baking pan can rotate around its own axis relative to the grill, But it cannot move horizontally, the fixed frame is fixedly installed on the outer wall of the cooking cavity, the motor is fixedly installed on the fixed frame, the outer wall of the baking pan is provided with teeth along the circumference, and the cavity wall of the cooking cavity is provided with through holes. The transmission gear is fixedly connected with the motor shaft of the motor, and can rotate around its own axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com