Magnetic filter

A magnetic filter and filter cartridge technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of increasing system complexity, maintenance costs, long cleaning time, and complicated procedures, and achieve high efficiency and safety. The effect of long-term operation, enlarged surface area, and improved removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0038] Carbon steel is a common material in compressed air preparation systems. After the system has been in operation for a period of time, carbon steel is easily corroded, resulting in granular or flake impurities containing iron ions. The invention relates to a magnetic filter for removing magnetic impurities and non-magnetic impurities from compressed air and other fluids.

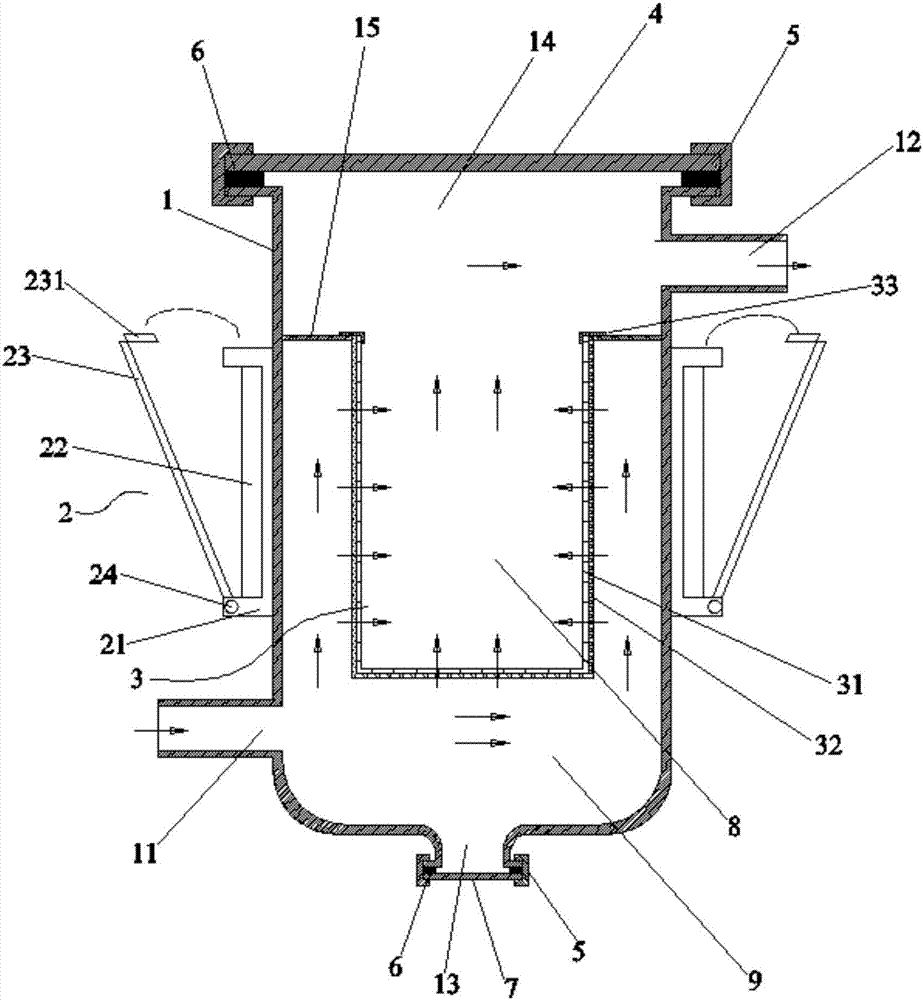

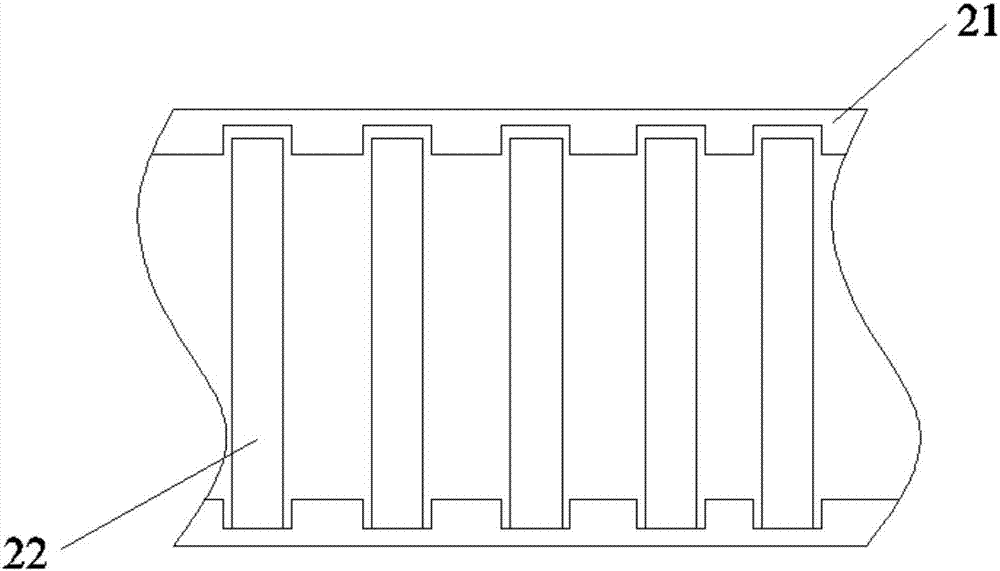

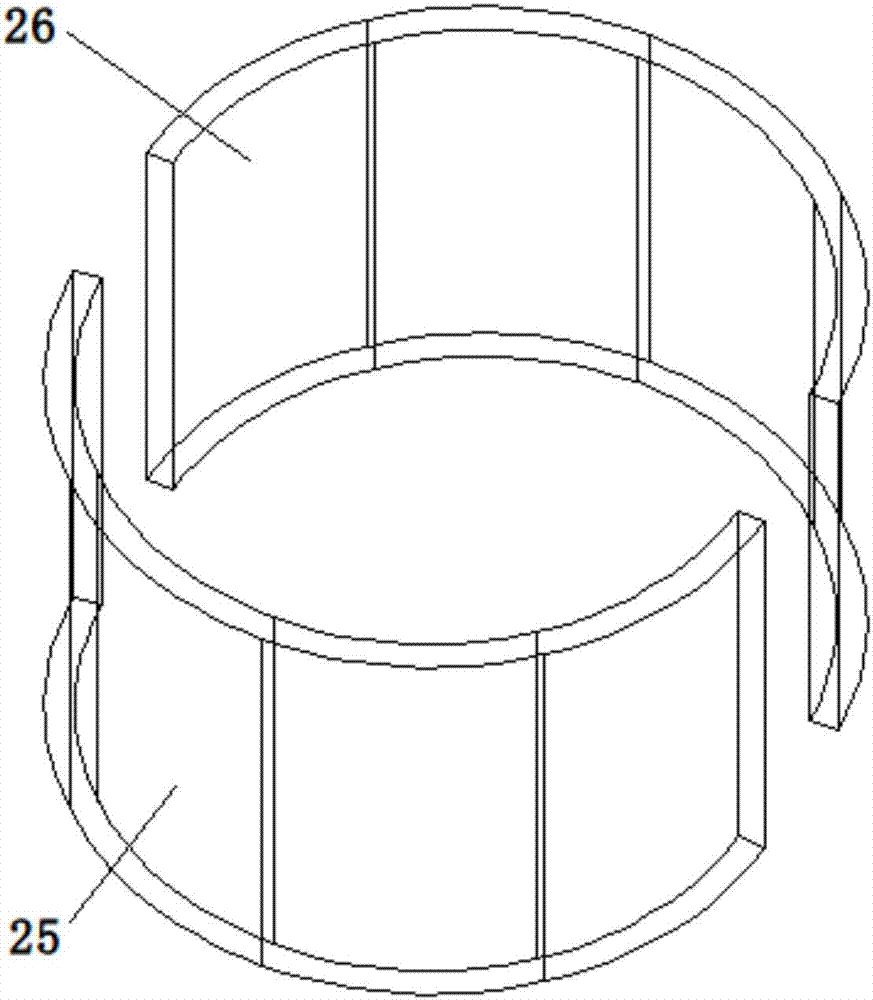

[0039] Such as figure 1 Shown is a schematic structural view of a magnetic filter according to an embodiment of the present invention. The magnetic filter is cylindrical as a whole and includes a stainless steel housing 1, a magnetic assembly 2 and a filter cartridge 3, wherein,

[0040] The housing 1 is provided with a fluid inlet 11 for allowing fluid to enter the housing 1 and a fluid outlet 12 for allowing fluid to exit the housing 1,

[0041]Certainly, in order to discharge the impurities adsorbed inside the housing 1 out of the housing 1 , a slag outlet 13 for discharging impurities in the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com