Efficient hook face dispensing machine

A technology of dispensing machine and curved surface, applied in the field of dispensing machine, can solve the problems of slow manual dispensing speed, difficult to guarantee dispensing accuracy, poor quality reliability and consistency, etc. Realize the effect of automatic flow operation and reliable dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

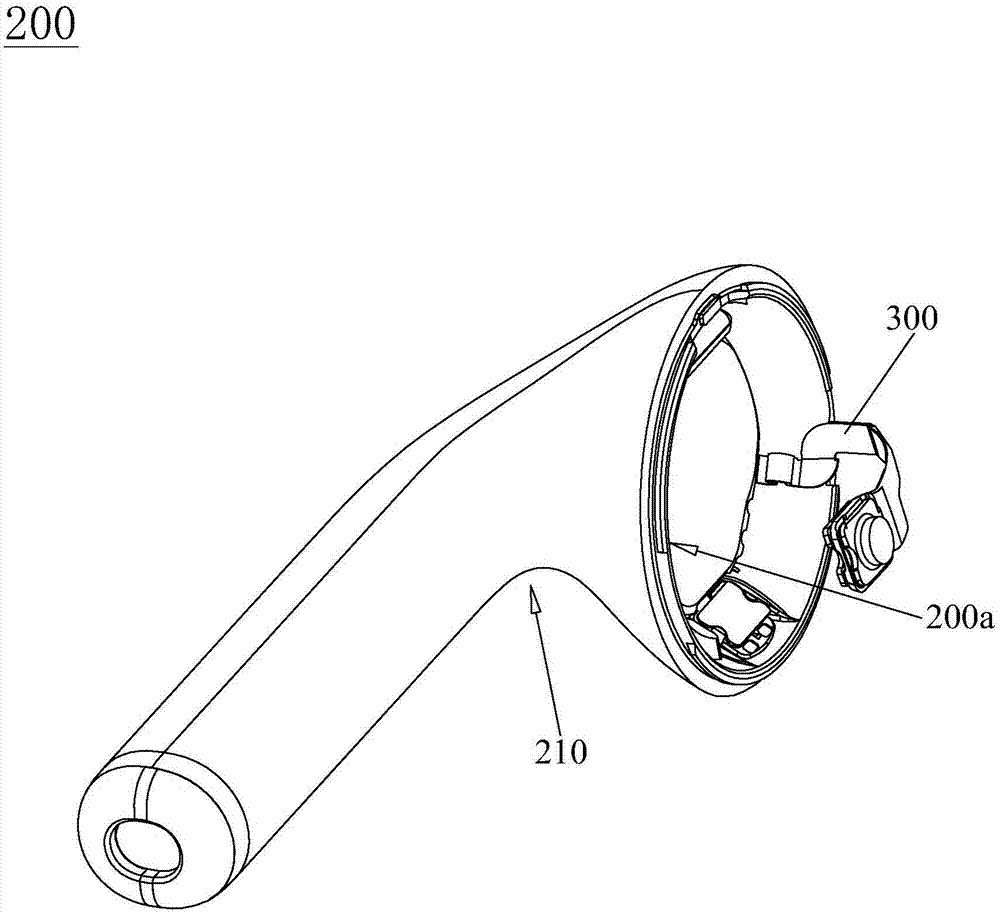

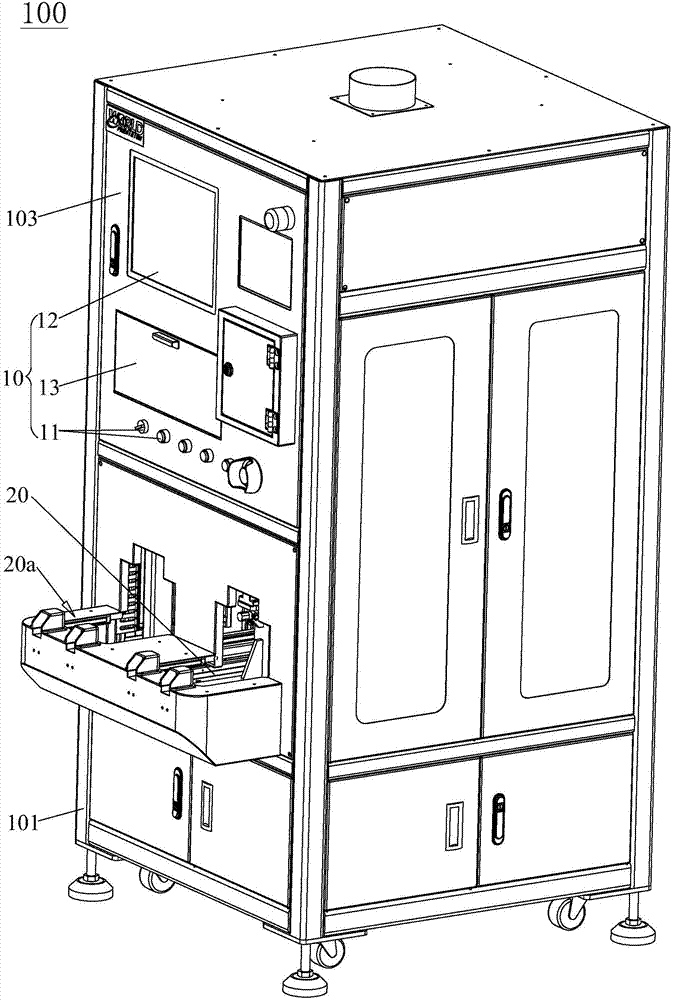

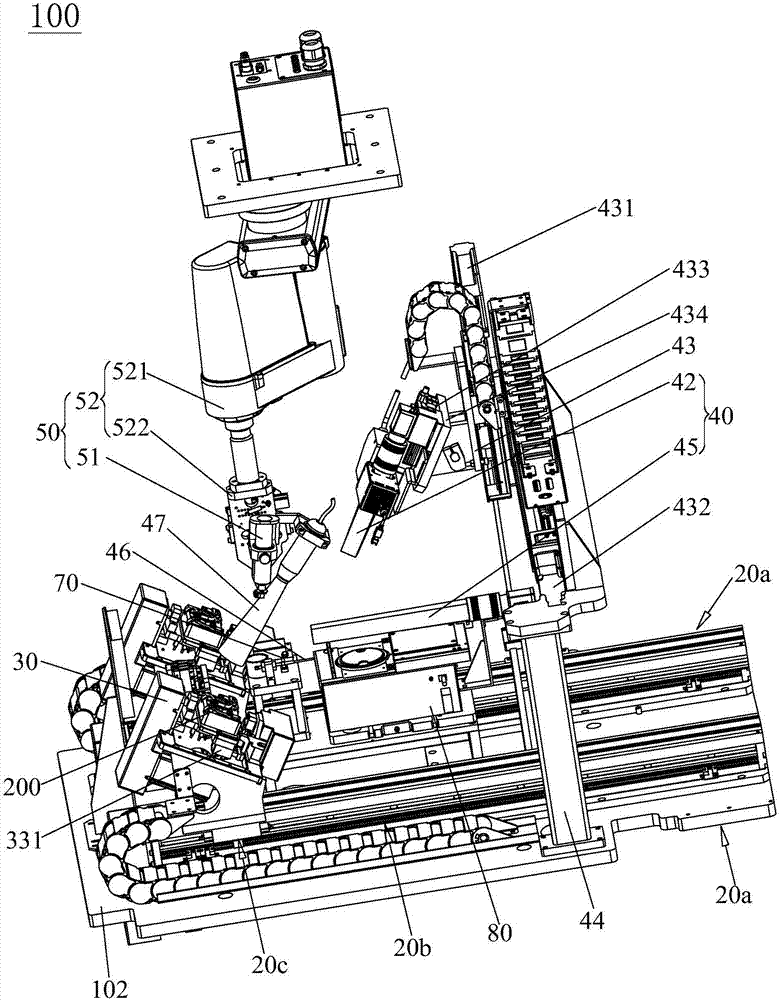

[0024] Please refer to Figure 1 to Figure 7 , the present invention discloses a high-efficiency curved surface dispensing machine 100, which is suitable for dispensing and sealing the assembly gap between the battery of the Bluetooth headset and the body 200, because the body 200 of the headset has a curved part 210, and the battery is packaged under the curved part 210 In order to seal the battery, it is necessary to dispense glue at the edge of the curved inner wall of the body 200 corresponding to the curved portion 210 and the edge of the battery to seal the assembly gap between the two. The needle needs to protrude into the housing 200 to reach the inner wall of the curved portion 210 to realize dispensing on the curved surface. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com