Aluminum plate printing and coating dedusting device

A technology of dust removal device and aluminum plate, applied in the direction of removing smoke and dust, cleaning methods and utensils, and cleaning methods using tools, etc., can solve problems such as failure to completely remove and collect furnace dust, polluted products, and time-consuming, and achieve enhanced dust removal effect. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

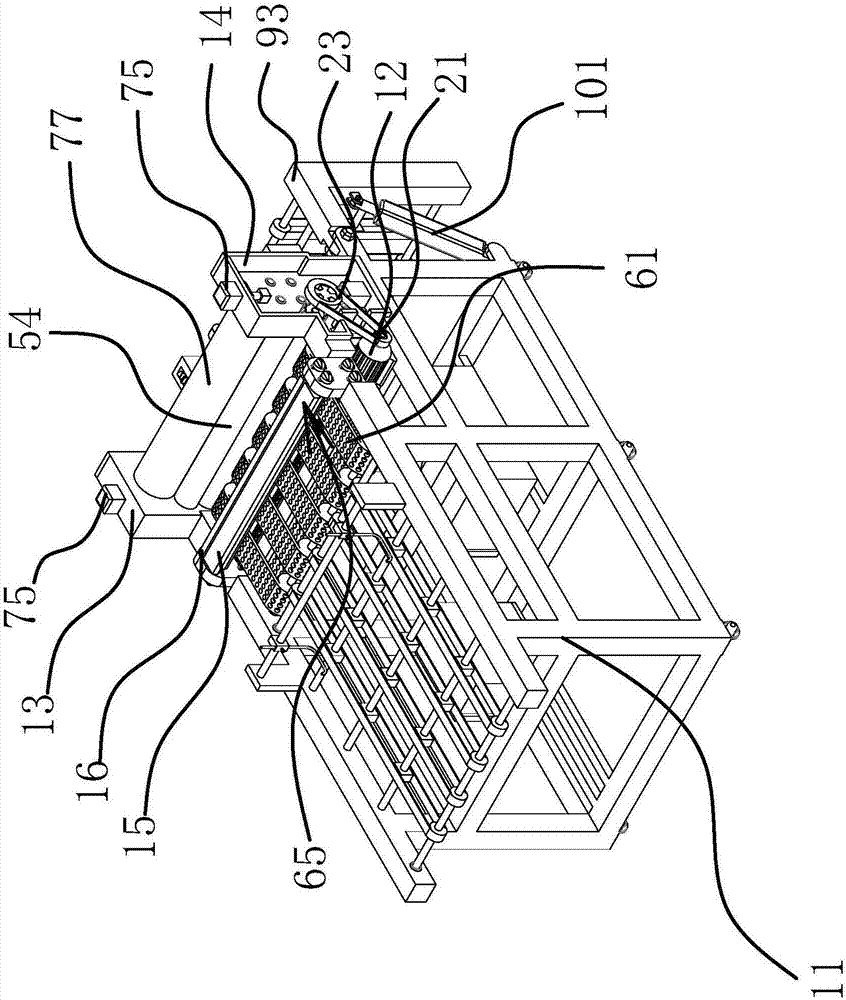

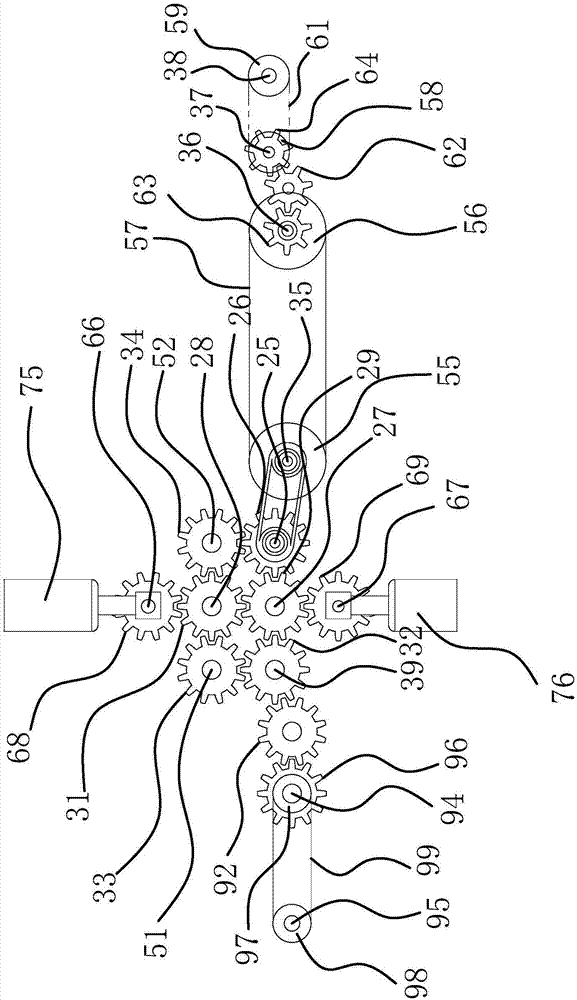

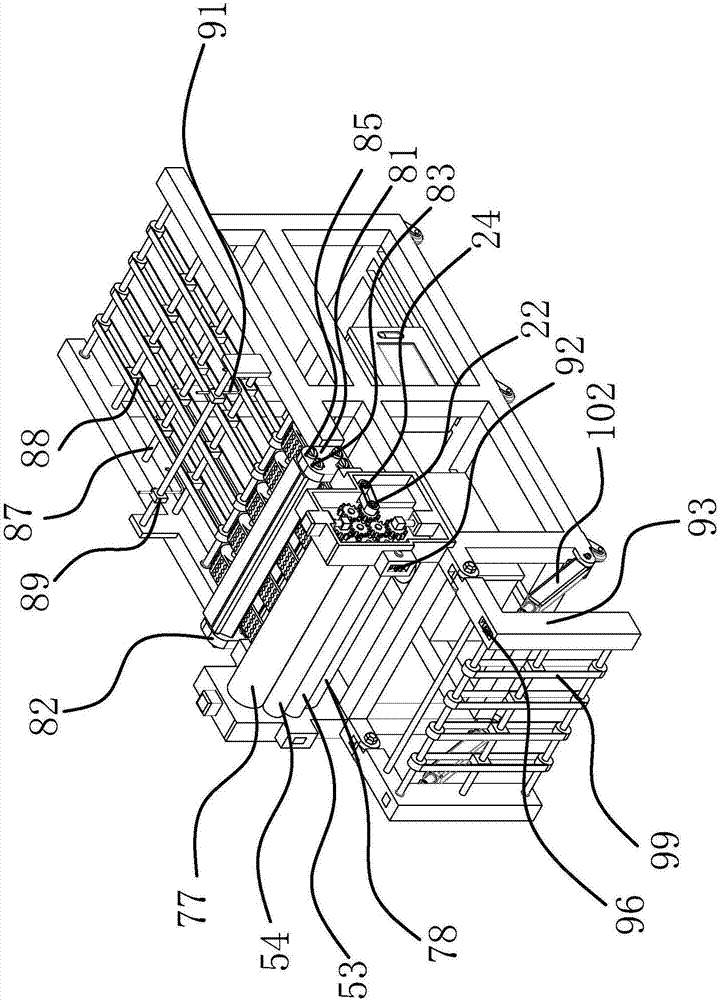

[0029] like figure 1 , figure 2 and image 3 As shown, the aluminum plate printing and coating dust removal device includes a frame 11, a drive motor 12 is fixedly arranged on the frame 11, and a mounting box one 13 and a mounting box two 14 are fixedly mounted on both sides of the frame 11, and the drive motor 12 Belt pulley one 21 is fixedly arranged on the output shaft, and a transmission shaft 25 is rotationally connected between the installation box one 13 and the installation box two 14, and the two ends of the transmission shaft 25 are respectively provided with belt pulley two 22 and belt pulley three 23, and on the transmission shaft 25 Output gear 26 is provided, rotating shaft one 27 and rotating shaft two 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com