Method for recognizing signal mode of cold-rolled strip

A pattern recognition and signal-based technology, applied in the field of cold-rolled strip, can solve the problems of complex identification model structure, insufficient accuracy and real-time performance, long network training time, etc. Interfering factors, the effect of improving training efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

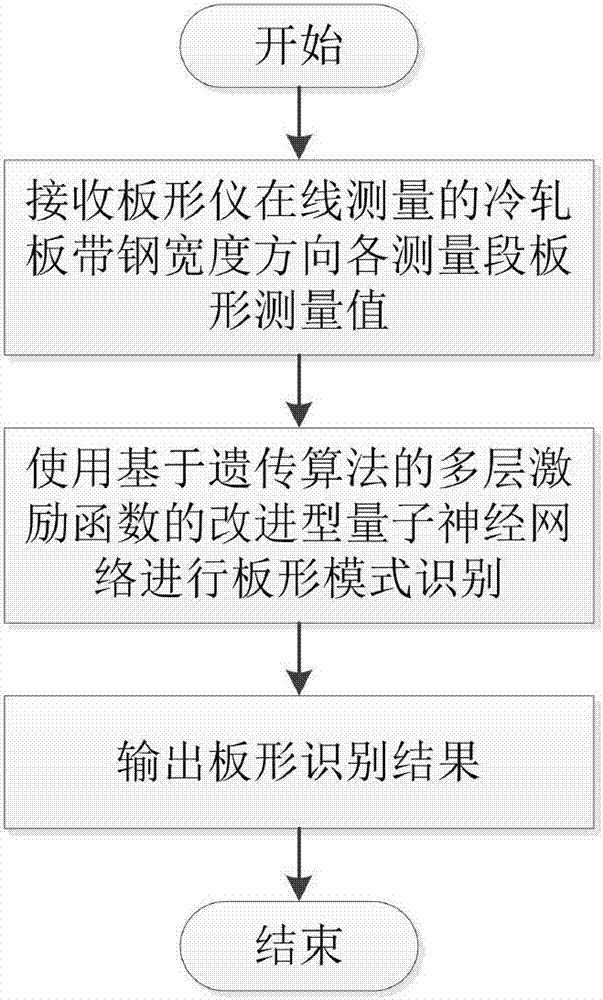

[0040] A method for signal pattern recognition of cold-rolled strips of the present invention, figure 1 It is a flowchart of an embodiment of the present invention, and it includes the following steps:

[0041] Step 1 collects the flatness measurement values of each measurement section in the width direction of the cold-rolled strip measured by the flatness meter online, and obtains the flatness value of each measurement section; let the number of measurement sections be m, m=15, the first i The measurement value of flatness of each measurement section is F i ;

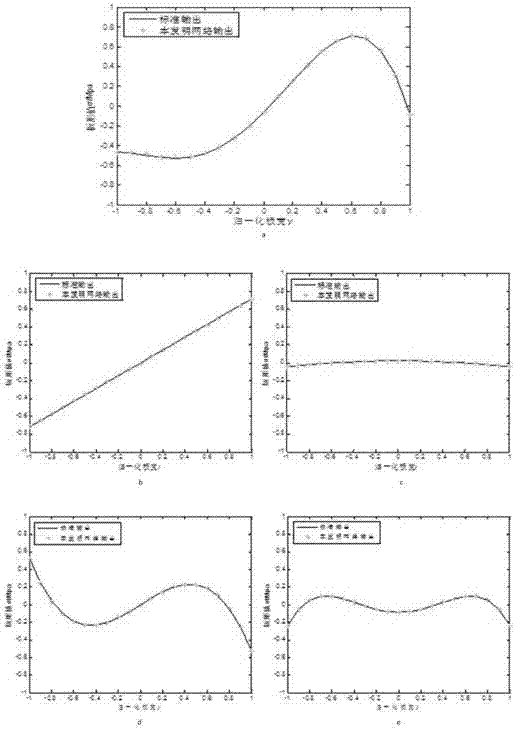

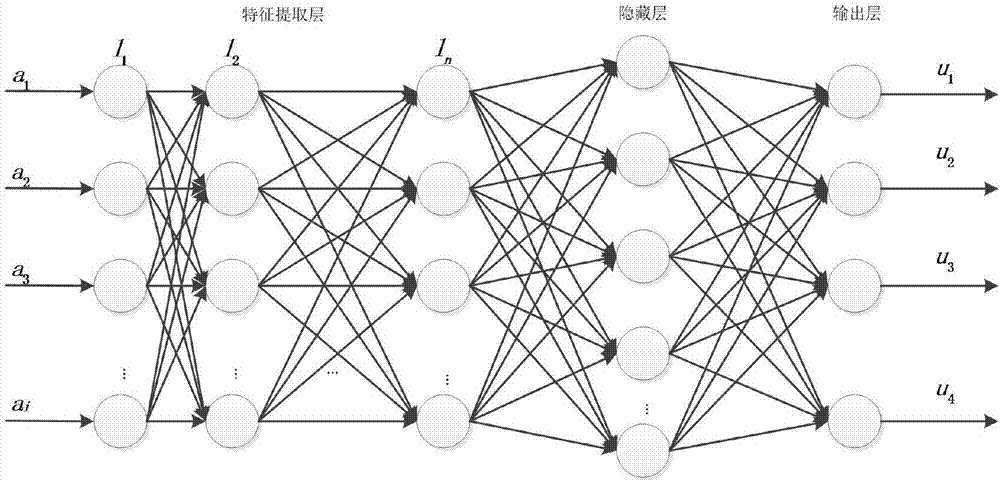

[0042] Step 2 Input the original data output by the shape meter into an n-layer neural network as the feature extraction layer, mainly through training to let the network automatically extract features to eliminate artificial traces; since the plate shape mainly has left waves, right waves,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com