Method and mold for surface densification and alignment of sintered components

A technology of densification and mould, applied in the direction of forming tools, manufacturing tools, material forming presses, etc., can solve the problems of limited use, unfavorable mechanical properties, etc., and achieve the effect of improving the precision of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

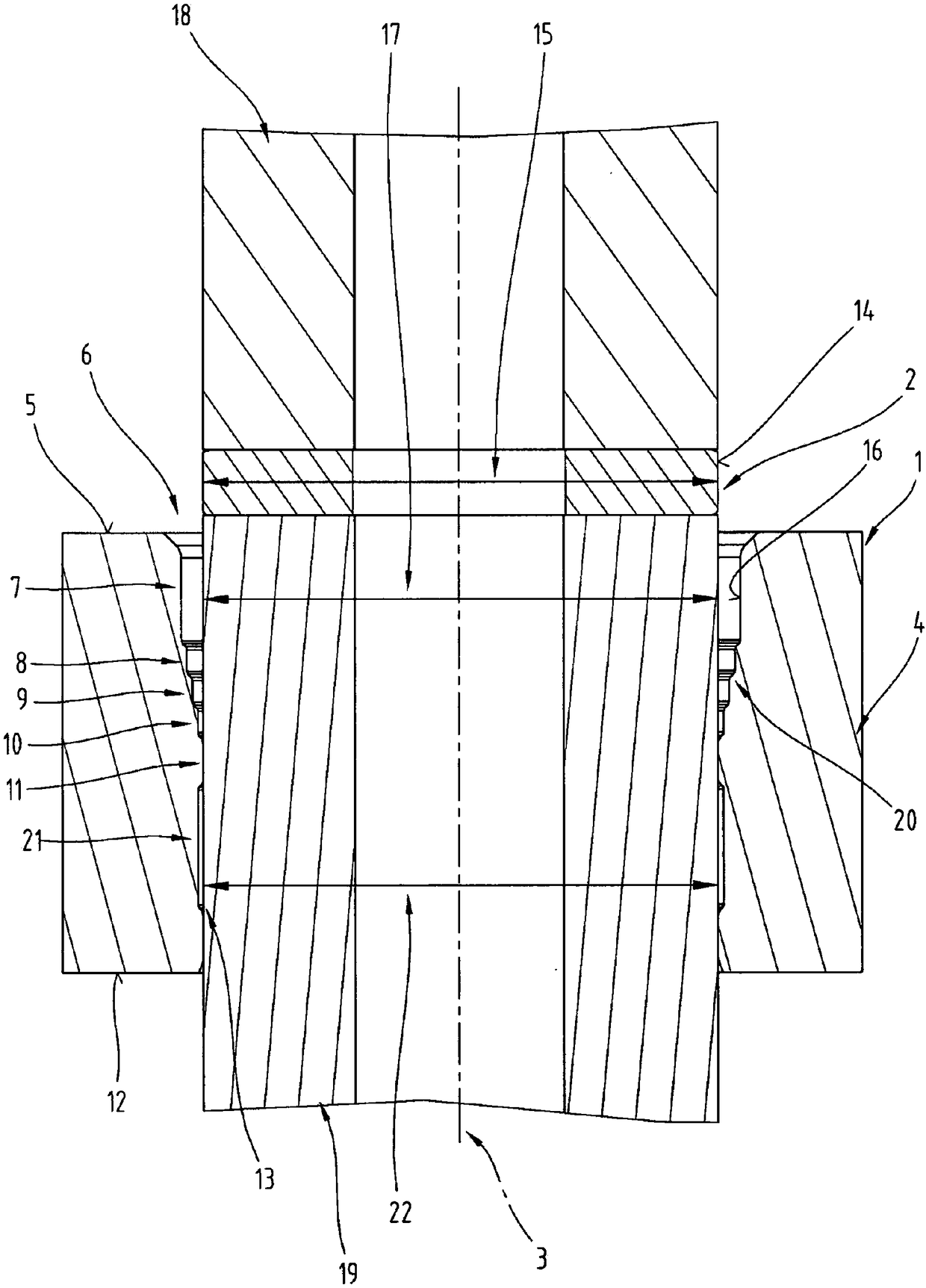

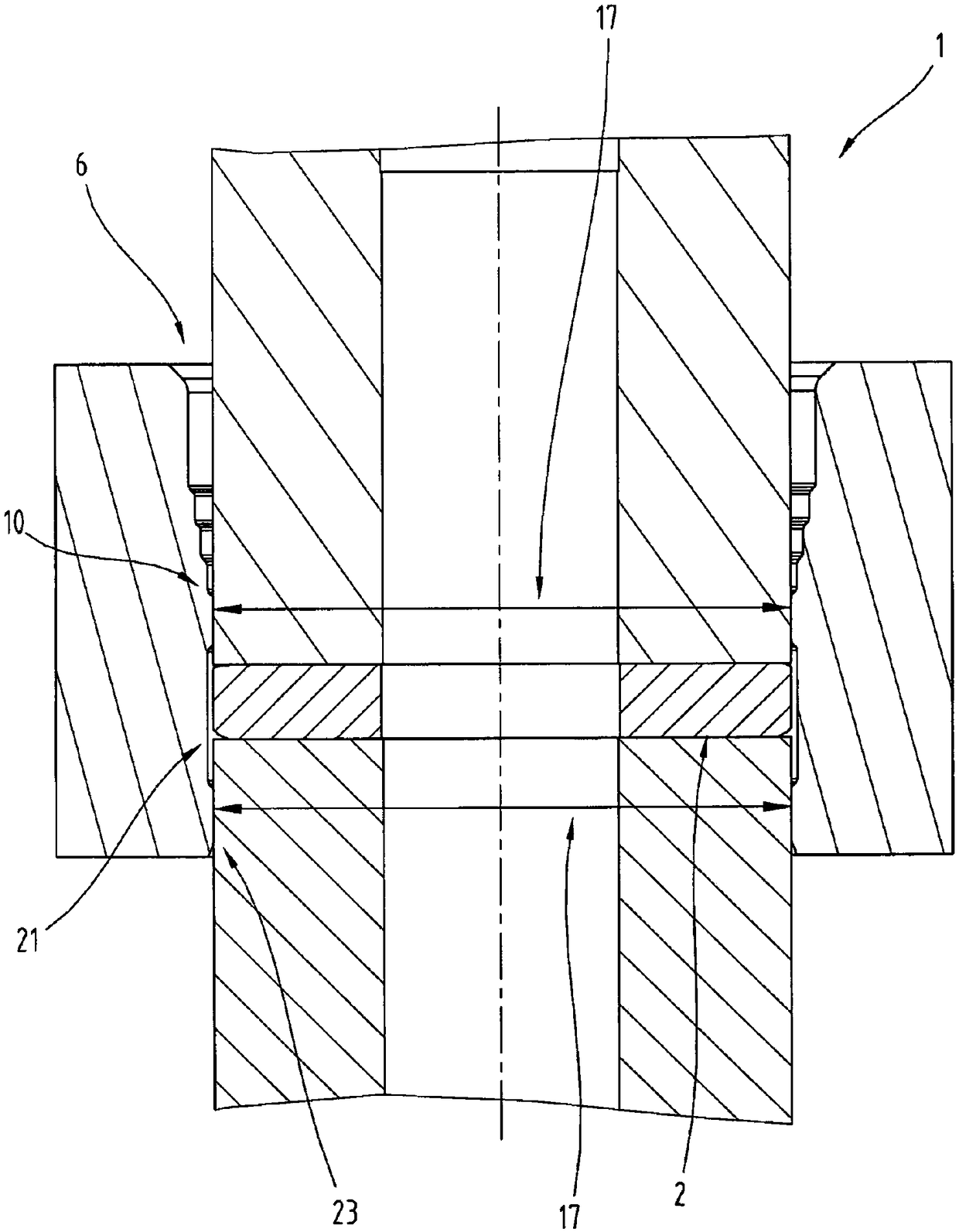

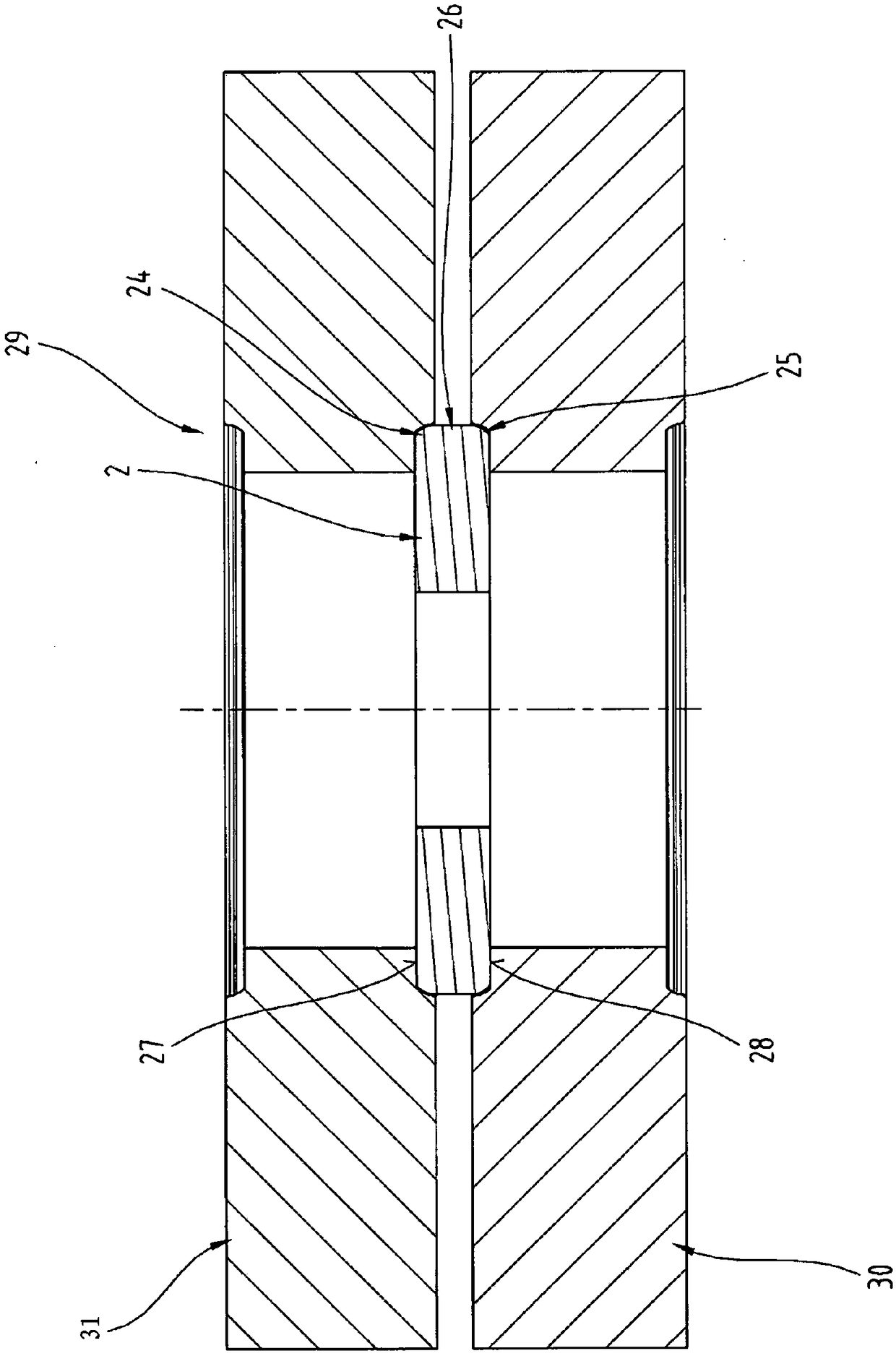

[0023] First of all, it should be confirmed that in the differently described embodiments, the same parts have the same reference signs or the same component designations, wherein the disclosure content contained in the entire description can be transferred to the same figure with the same figure Mark or on the same part of the same component name. Furthermore, selected positional descriptions in the description, such as top, bottom, side, etc., refer to the currently described or illustrated drawing and can be transferred to a new position in the event of a change of position.

[0024] It should be noted here that the calibration of the sintered component means that the sintered component is processed in a mold by a compression load in order to achieve at least approximately the theoretical dimensions of the component. "At least approximately" here means that deviations from the theoretical dimensions within customary tolerances are permissible.

[0025] The term "theoretica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com