Roller type metallurgy powder mixing device

A metallurgical powder and material mixing device technology, which is applied in transmission devices, gear transmission devices, belts/chains/gears, etc., can solve the problems of restricting the production efficiency of mixing materials, and achieve the effect of balanced ratio of each diameter and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

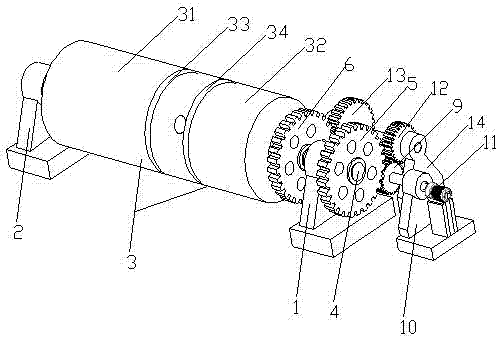

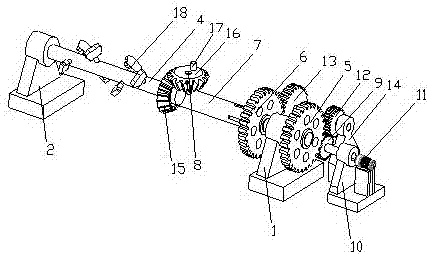

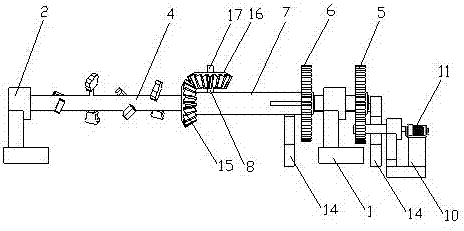

[0026] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0027] see Figure 1 to Figure 5 , the present invention is a drum-type metallurgical powder mixing device, which includes a base A1 and a base B2 that are oppositely arranged, a power mechanism that bridges between the base A1 and the base B2, and a drive mechanism that abuts the power mechanism, The transmission structure arranged on the output shaft of the power mechanism accommodates the output shaft of the power mechanism and the mixing bin 3 of the transmission structure. The inside of the mixing bin 3 is provided with a partition 33 that separates it into a mixing bin 31 and a transmission bin 32. An annular guide groove 34 is provided on the inner wall of the transmission chamber 32 .

[0028] The power mechanism includes a central transmission shaft 4 that runs through the base A1 and the top ring sleeve of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com