Method for mounting bush on shell and used bush pressing tool

A bushing and shell technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of rising production costs, too long pressing time, affecting product delivery, etc., to achieve low production costs, small loss of tooling, and shortened work the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

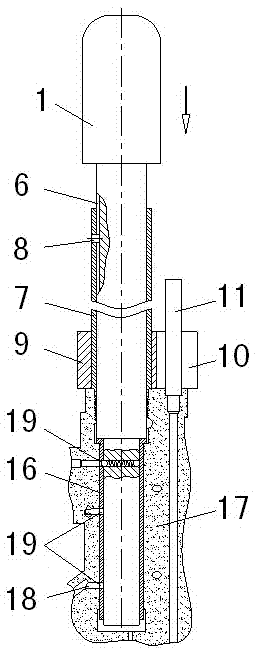

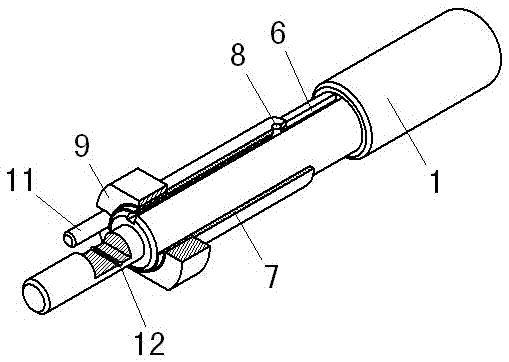

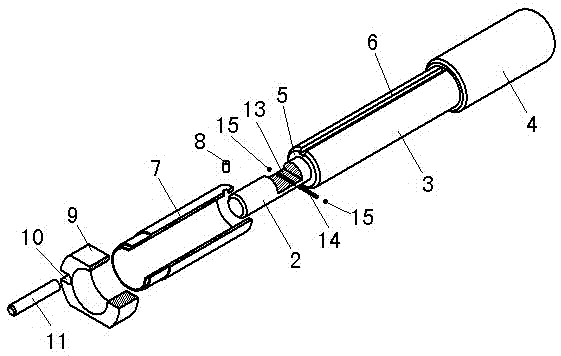

[0019] The compression sleeve tooling used in this example is as follows: figure 1 and figure 2 As shown, it is made up of a pressure sleeve rod 1, a spring 14, a positioning pin 11, two steel balls 15, a positioning sleeve 9, and a guide sleeve 7. Two steel balls 15 and a spring 14 are loaded into the pressure sleeve rod 1 to form the structure of the spring top ball 12, which is used as a clamping structure for the bushing 16 to be installed on the pressure sleeve rod 1, and the positioning groove 6 in the middle of the pressure sleeve rod 1 and the guide sleeve The slide pin 8 that slides in 7 forms the slot orientation structure, which is used for the orientation when pressing the sleeve. The guide sleeve 7 is connected with the positioning sleeve 9 by welding, and the positioning sleeve 9 is provided with a positioning gap 10, and a positioning pin 11 is inserted therein for tool positioning.

[0020] The bushing tooling is a kind of auxiliary tooling for pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com