Distribution board improving mold

A switchboard and mold technology, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as the inability to meet the processing requirements of high-precision automotive switchboards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, should be understood that structure of the present invention is not limited to following embodiment:

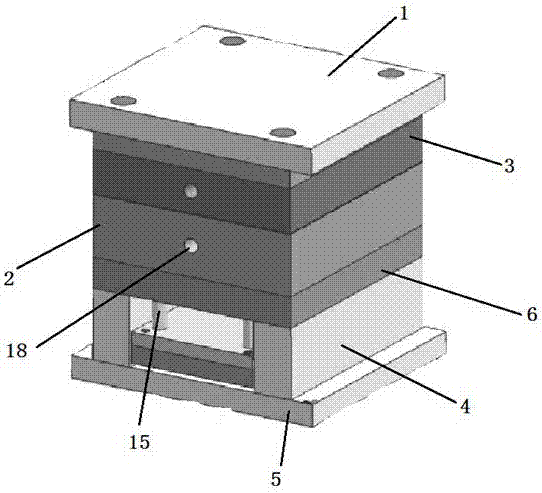

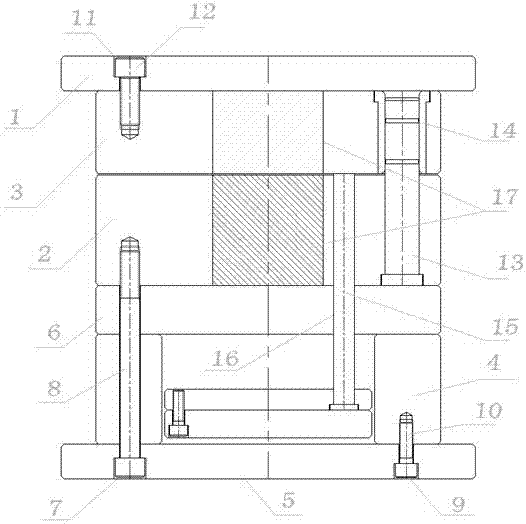

[0016] Such as Figure 1-2 As shown, a switchboard improved mold, including top plate 1, A plate 2, B plate 3, cushion block 4 and bottom plate 5, the B plate 3 is a movable mold set at the bottom of the top plate 1, and the A plate 2 is a fixed mold It is arranged under the B board 3, and the pads 4 are connected to the bottom plate 5 and are all arranged under the A board 2. A bearing plate 6 is also provided between the A board 2 and the pads 4, and the bottom board 5 is provided with The first installation hole 7 connecting the A plate, the bearing plate, the spacer and the bottom plate is fastened by the first bolt 8, and the second installation hole 9 connecting the spacer and the bottom plate is also provided on the bottom plate 5 and is passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com