Repairing method of PE (Poly Ethylene) armor plate

A technology of bulletproof board and repair glue, which is applied in the repair field of PE bulletproof board, can solve the problems of poor adhesion, high cost, loss of bulletproof performance of PE bulletproof board, etc., and achieves the reduction of use cost, low repair cost, simple and feasible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

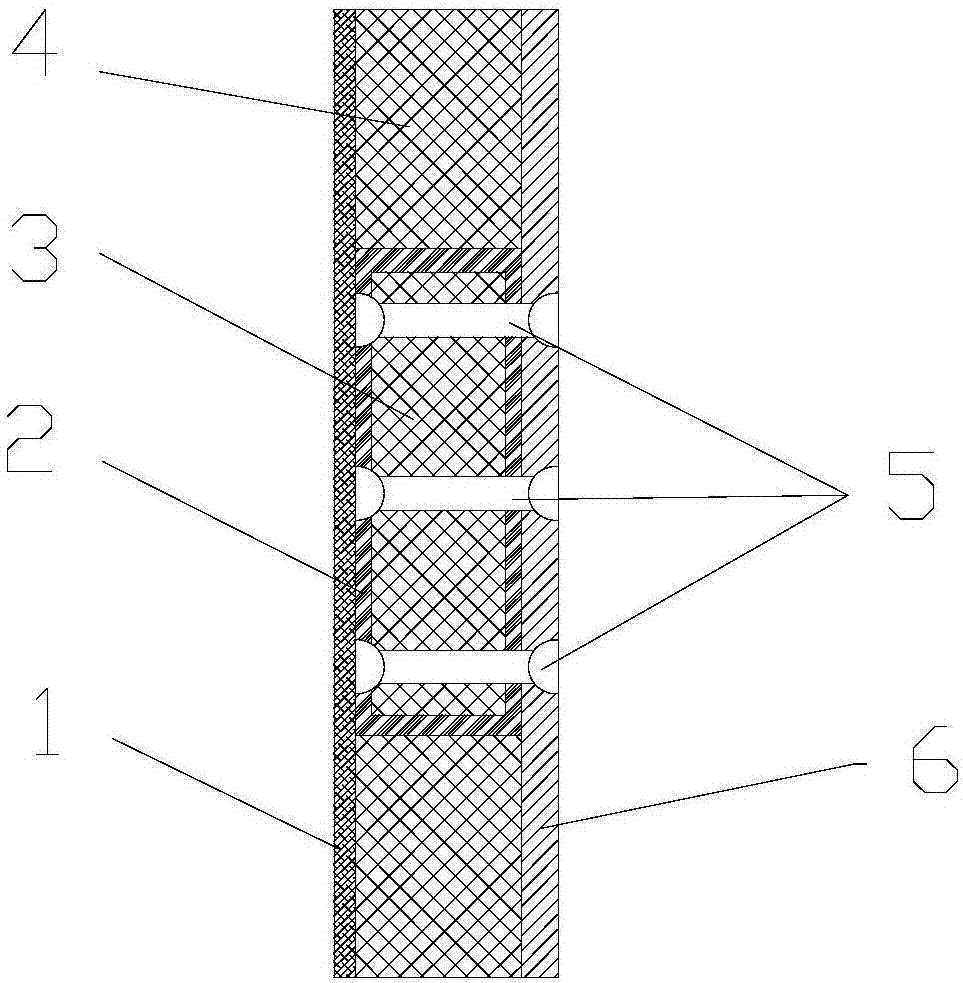

[0027] Installation of PE bulletproof plate: use 20mm thick PE bulletproof plate 4 as the bulletproof material, drill holes around the PE bulletproof plate 4 at a distance of 200mm, the hole diameter is 5mm, and then bond the same size 0.5mm thick on the back of the PE bulletproof plate 4 The surface of the aluminum plate 6 is bonded to the panel 1 with the same size and thickness of 0.3 mm; pressed for 2 hours at a temperature of 60°C, cooled naturally for 4 hours, and directly riveted on the equipment with rivets.

[0028] see figure 1 , the repair method of PE bulletproof plate, the steps are as follows:

[0029] (1), cutting of PE bulletproof plate 4: adopt hand-held cutting machine to cut panel 1 and PE bulletproof plate 4 in the PE bulletproof plate area of bulge from panel 1 side, adopt stopper during cutting, in order to avoid damaging aluminum plate 6; Limit the cutting depth to 19mm, cut out a square hole of 300mm×300mm centered on the bulge area, and remove the d...

Embodiment 2

[0035] Installation of PE bulletproof plate: use 24mm thick PE bulletproof plate 4 as the bulletproof material, drill holes around the PE bulletproof plate 4 at a distance of 200mm, the hole diameter is 5mm, and then bond the same size 0.7mm thick on the back of the PE bulletproof plate 4 The surface of the aluminum plate 6 is bonded to the panel 1 with the same size and thickness of 0.5 mm; pressed for 2 hours at a temperature of 60°C, cooled naturally for 4 hours, and directly riveted on the equipment with rivets.

[0036] The repair method of PE bulletproof plate, the steps are as follows:

[0037] (1) Cutting of PE bulletproof plate: Use a hole opener with a diameter of 300mm to cut the panel 1 and PE bulletproof plate 4 in the bulging PE bulletproof plate area from the side of panel 1, and limit the cutting depth to 23mm. As the center, cut out a round hole with a diameter of 300mm, and remove the damaged panel 1 and PE bulletproof plate 4; use a stopper when cutting to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com