Security feature identification method and reflection type safety element film

A security element and security feature technology, applied in special patterns, patterns characterized by light projection effects, decorative arts, etc., can solve the problems that cannot be further thinned, security elements cannot respond dynamically to light, restrict the scope of application and safety performance, etc. , to achieve high anti-counterfeiting safety performance, compact structure, and thin overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

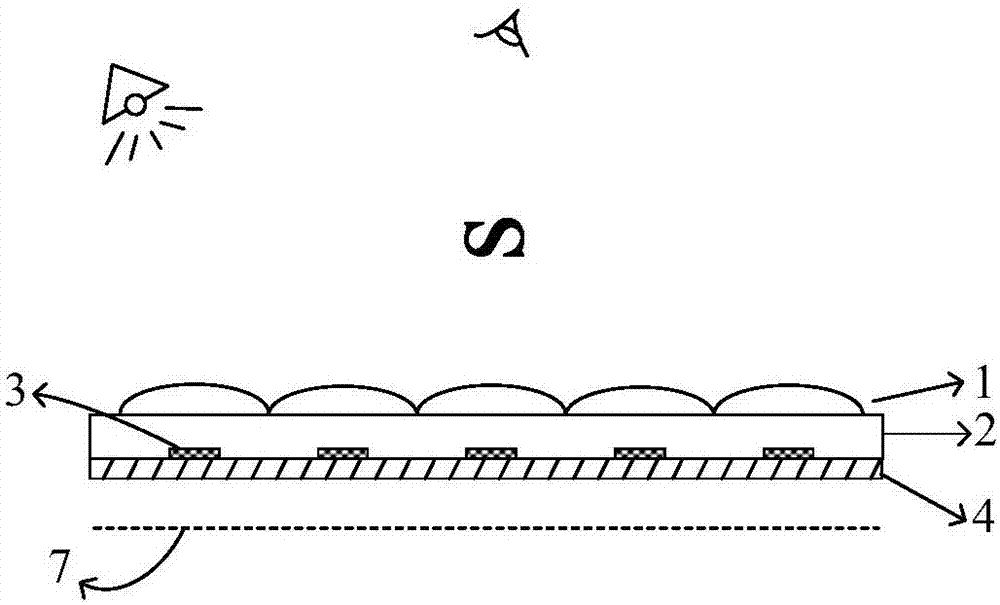

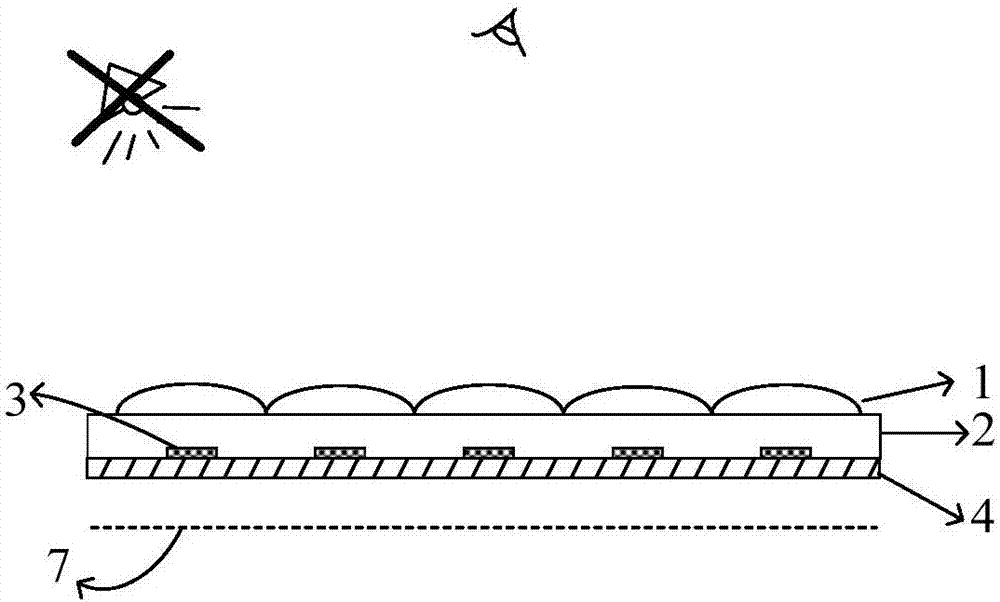

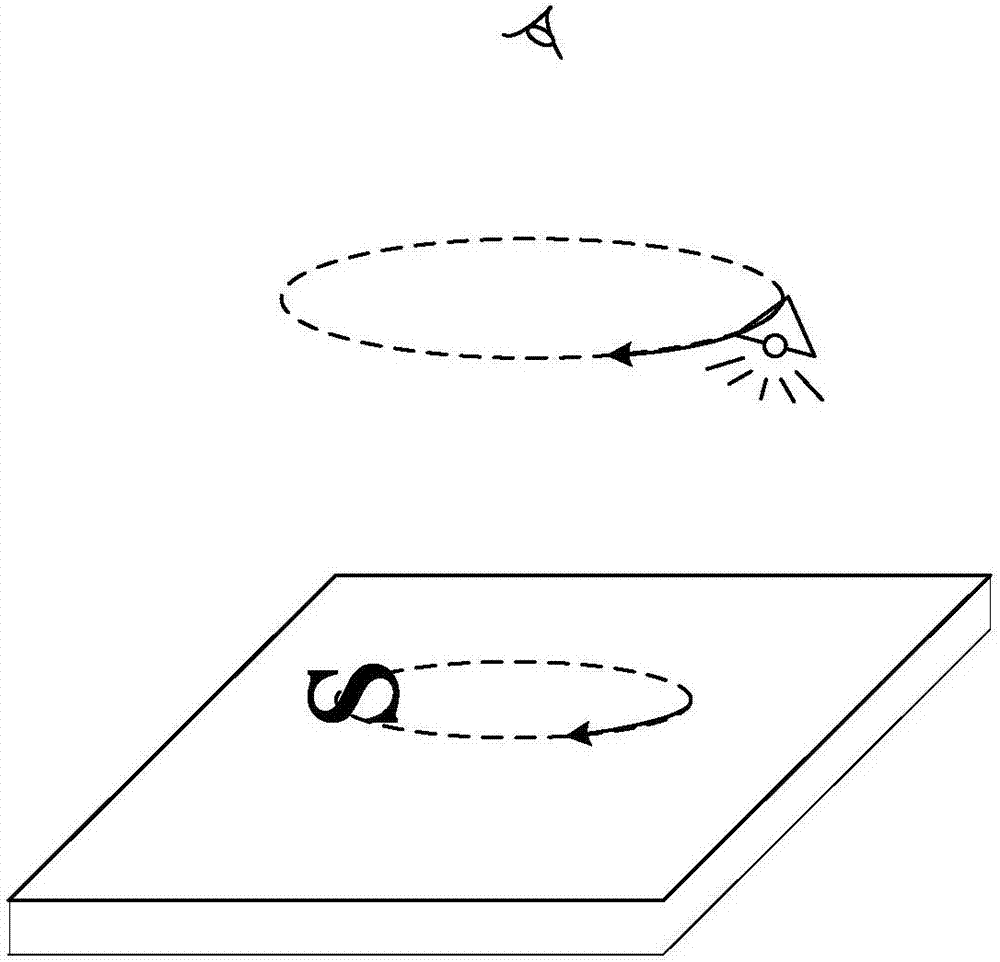

[0052] This embodiment provides a reflective security element film and its security identification identification method, such as figure 1 and 2 As shown, it includes a focusing element array layer 1, a substrate layer 2, a reflective layer 4 and a micro-text array layer 3, and the focusing element array layer 1, the substrate layer 2, and the reflective layer 4 are sequentially bonded, and the micro-text array Layer 3 is obtained by setting microtext (microtext unit) on a transparent substrate. The focusing element array layer 1 is composed of spherical lens units arranged orthogonally, and the array period is T. The micro-text units are arranged orthogonally, and the array period is 1.005T. The symmetry axis of the focusing element array and the symmetry axis of the micro-text unit array are parallel to each other. The microtext unit is located at 0.2 times the focal length of the focusing element array.

[0053] Such as figure 1 As shown, under the illumination of a po...

Embodiment 2

[0057] This embodiment provides a reflective security element film and its security identification identification method, such as Figure 4 and 5 As shown, it includes a focusing element array layer 1, a base material layer 2, a reflective layer 4 and a micro-graphic array layer 3, and the focusing element array layer 1, the base material layer 2, and the reflective layer 4 are bonded in sequence, and the micro-image The text unit is embedded in the substrate layer 2 to form the micro-text array layer 3 . The focusing element array layer 1 is composed of spherical lens units arranged orthogonally, and the array period is T. The micro-text units are arranged orthogonally, and the array period is 0.995T. The symmetry axis of the focusing element array and the symmetry axis of the micro-text unit array are parallel to each other. The microtext unit is located at 0.1 times the focal length of the focusing element array.

[0058] Such as Figure 4 As shown, under the illuminat...

Embodiment 3

[0062] This embodiment provides a reflective security element film, such as Figure 7 and 8 As shown, it includes a focusing element array layer 1, a base material layer 2, a reflective layer 4 and a micro-graphic array layer 3, and the reflective layer 4, the focusing element array layer 1, and the base material layer 2 are bonded in sequence, and the micro-image The text unit is embedded in the substrate layer 2 to form the micro-text array layer 3 . The focusing element array layer 1 is composed of spherical lens units arranged orthogonally, and the array period is T. The micro-text units are arranged orthogonally, and the array period is 1.003T. The symmetry axis of the focusing element array and the symmetry axis of the micro-text unit array are parallel to each other. The microtext unit is located at 0.2 times the focal length of the focusing element array.

[0063] Such as Figure 7 As shown, under the illumination of a point light source, the light passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com