Treatment process of valve rod of valve

A treatment process and valve stem technology, which is applied in the field of valve stem treatment process, can solve the problems of long nitriding cycle, difficult quality assurance, high cost, etc., and achieve the effects of improving production efficiency, shortening production cycle and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

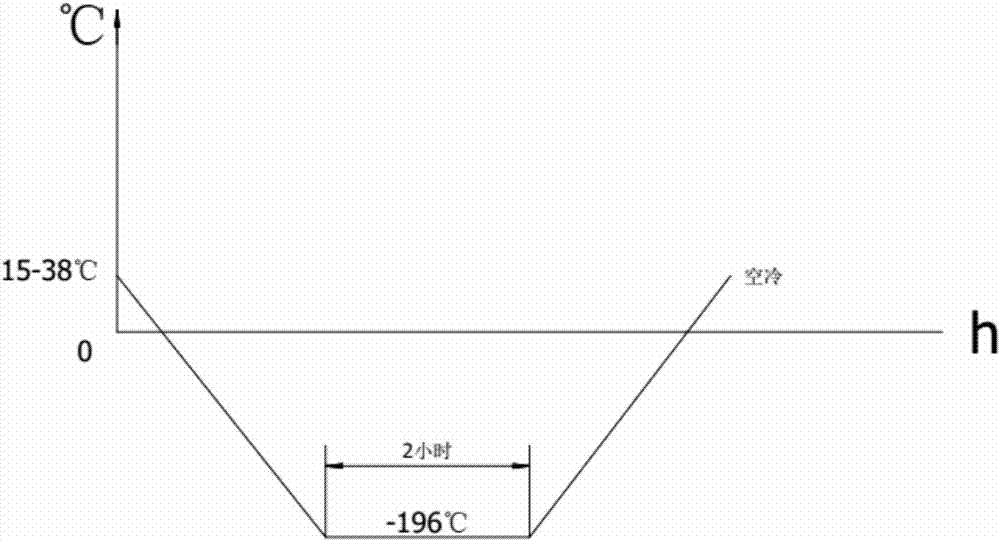

[0022] A valve stem treatment process, including the valve stem, wherein the valve stem material is F304 (0Gr18Ni9) austenitic stainless steel, the valve stem material is subjected to solid solution heat treatment, and then placed in a cryogenic bath at -196°C Liquid nitrogen was sent for cryogenic treatment.

[0023] Such as figure 1 As shown, the cryogenic treatment process steps are:

[0024] 1. Wipe the outer surface of the valve stem with Bing copper, so that the outer surface of the valve stem is free of moisture and debris;

[0025] 2. Place the valve stem in the cryogenic tank, and the gap between two adjacent valve stems is 10mm;

[0026] 3. Close the cryogenic cover and seal it;

[0027] 4. Turn on the liquid nitrogen switch, start delivering liquid nitrogen, and check the instrument thermometer;

[0028] 5. When the instrument thermometer reaches -190 degrees, the surface of the workpiece begins to emit white bubbles. After the bubbles are full, keep warm for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com