Clamping device for bag opening machine

The technology of a clamping device and a bag-opening machine is applied in the field of sewing machines, which can solve the problems of increased production cost of a single piece of enterprises, high labor intensity of operators, and finger damage of operators, and achieves a simple structure, easy to work, and avoids finger damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

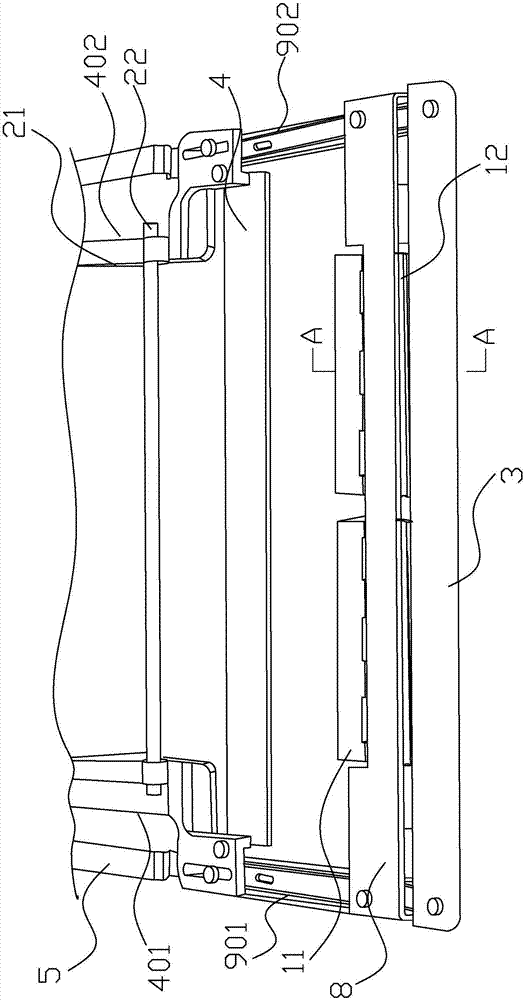

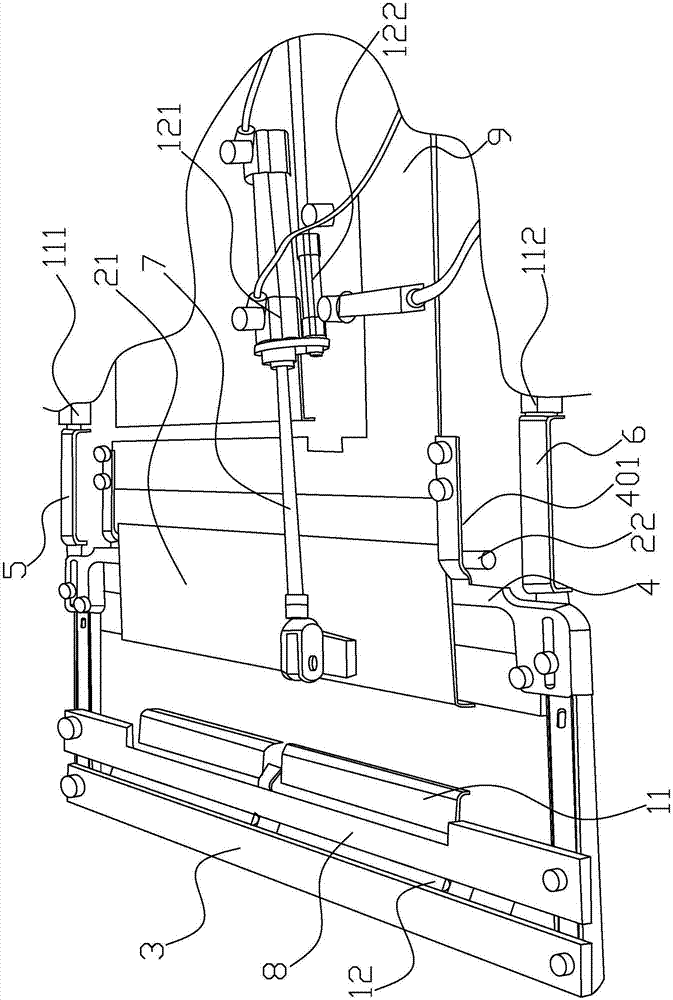

[0023] refer to Figure 1-Figure 4, the clamping device of the preferred bag opening machine of the present invention includes a controller, a fixed frame 9, a first drive mechanism, a second drive mechanism, a first claw mechanism, a second claw mechanism, a moving seat 3, and a fixed seat 4. The first connecting rod 5, the second connecting rod 6, the third connecting rod 7, the pressing plate 8 and the upper cover 10, the fixed frame 9 is arranged on the sewing table of the bag opening machine, the moving seat 3 and The fixed seat 4 is arranged on the front and the rear part of the fixed frame 9 parallel to each other and symmetrically, wherein the fixed seat 4 is positioned at the inner side of the machine needle on the sewing table of the bag opener, and the movable seat 3 is positioned at the outside, and the first driving mechanism Including a first cylinder 111 and a second cylinder 112, the output ends of the first cylinder 111 and the second cylinder 112 are respecti...

Embodiment 2

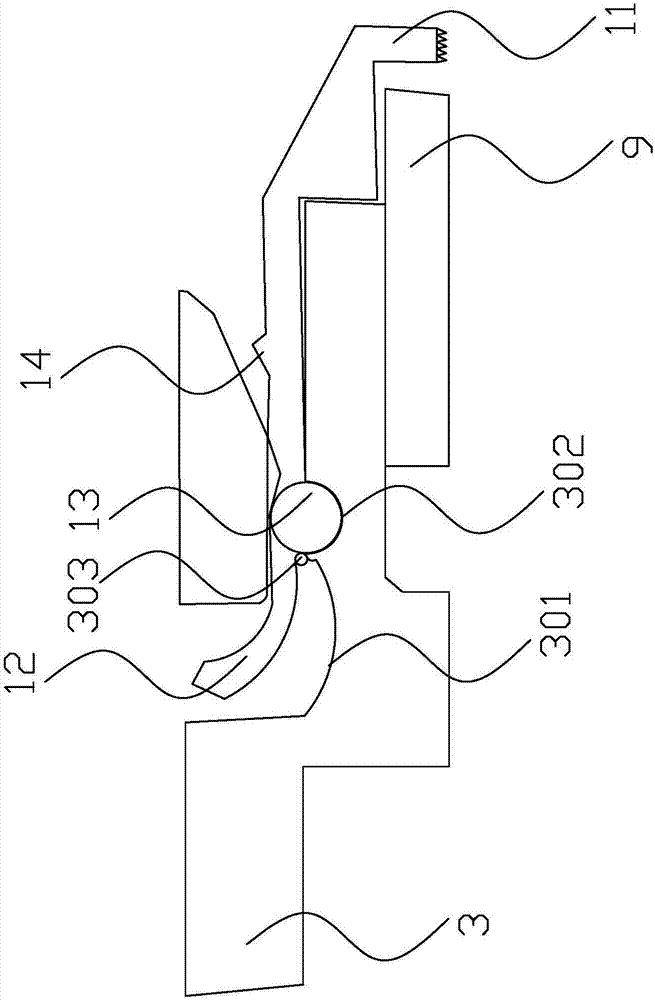

[0025] refer to Figure 5 , the difference from the solution in the first embodiment is that the modeling structure among the moving seat, the fixed frame, the pressing plate and the first jaw mechanism is different, so in the second embodiment only the difference is described and introduced, refer to Figure 5 , the clamping device of the preferred bag opening machine of the present invention includes a controller, a fixed frame 9', a first drive mechanism, a second drive mechanism, a first claw mechanism, a second claw mechanism, a moving seat 3', a fixed Seat, the first connecting rod, the second connecting rod, the third connecting rod and the pressing plate 8', the front part of the first pressing claw mechanism is provided with a pressing claw 11' for stabilizing the cloth, and the rear of the first pressing claw mechanism The part is provided with an upwardly tilted arc portion 12', and the side of the first claw mechanism away from the arc portion 12' is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com