Automated device and method for supplying and discharging oil

A technology of oil unloading pipe and oil supply pump, which is applied in the field of machinery, can solve the problems of complex structure and inconvenient transportation of steam injection boilers in oil fields, and achieve the effects of easy relocation and transportation, easy operation, and avoiding airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

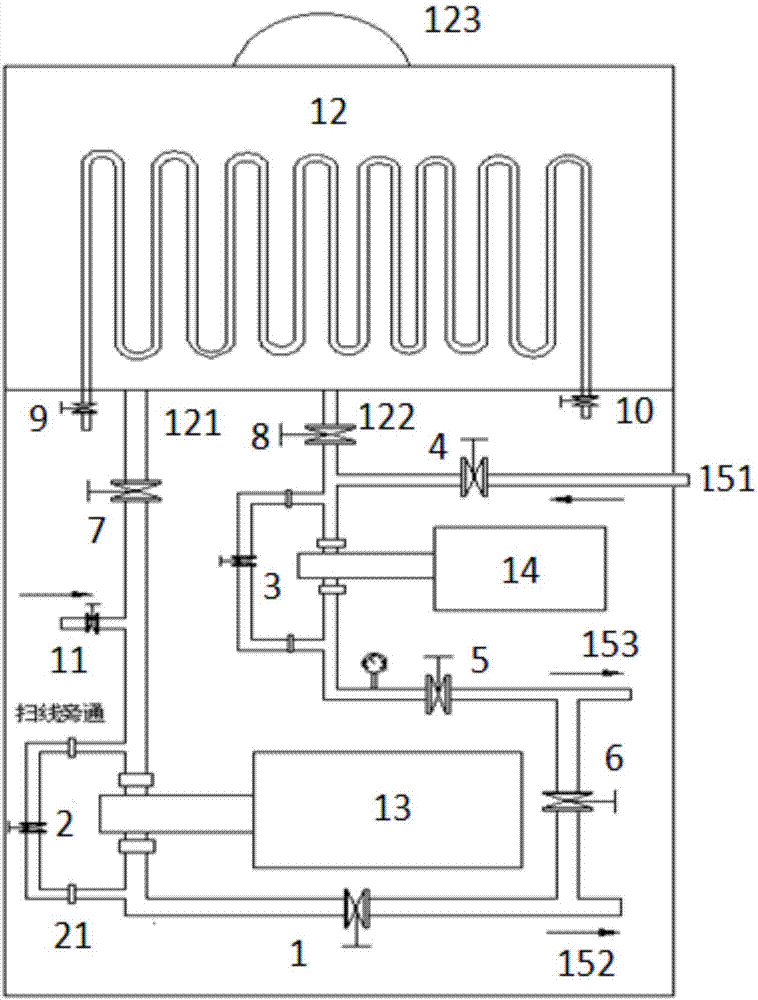

[0025] In order to solve the problem of complex structure of oilfield steam injection boilers in the prior art, the embodiment of the present invention proposes a figure 1 Shown is an automatic oil supply and unloading device for automatic oil supply, oil unloading, and line sweeping for steam injection boilers in oil fields, which includes: oil unloading tank 12, oil unloading pump 13, and oil supply pump 14;

[0026] Wherein the oil unloading tank 12 is provided with an oil unloading tank outlet 121 and an oil unloading tank inlet 122;

[0027] Wherein, the unloading pump 13 is provided with a first three-way, and the first three-way is connected to the outlet 121 of the oil unloading tank through the pipeline provided with the seventh valve 7, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com