Control method for phase change heat storage heating system

A phase-change heat storage and heating system technology, applied in heating systems, heating methods, and central heating, can solve problems such as increasing the complexity of pipeline and equipment layout, and increasing equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

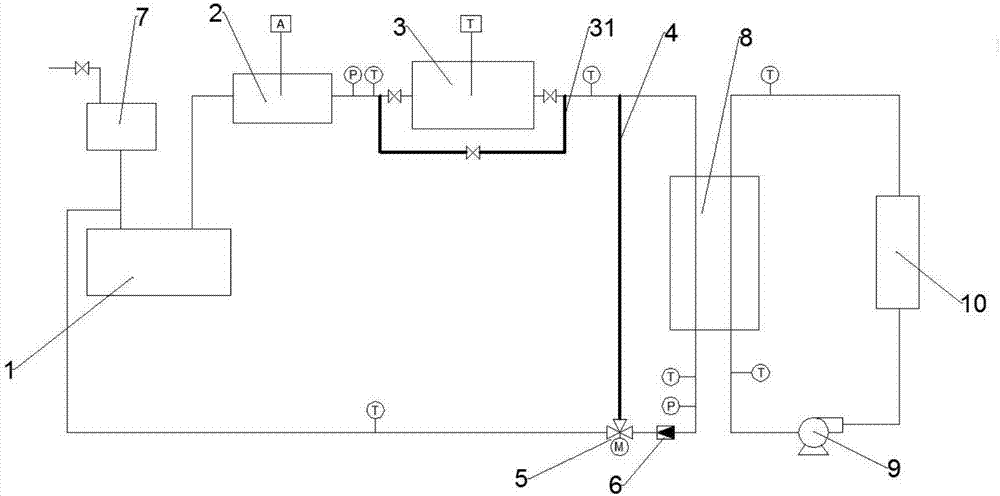

[0050] A phase change thermal storage heating system, including a heat supply cycle system, a load cycle system, heat exchange between the heat supply cycle system and the load cycle system through a heat exchange device 8; the heat supply cycle system includes an electric boiler 1, a heat supply cycle power device 2. Phase-change heat storage heat store 3, shunt pipe 4, the electric boiler 1, heat supply cycle power unit 2, phase-change heat storage heat store 3, and heat exchange device 8 are connected sequentially through heat supply cycle pipelines; 4 is set on the heat supply circulation pipeline and connected in parallel with the heat exchange device 8; the junction of the outlet pipe of the heat exchange device 8 and the branch pipe 4 is provided with a flow diverter regulator 5.

[0051] Wherein, the heat supply cycle system is used as a heat source system, and the heat is transferred to the load cycle system through the heat exchange device 8, and the load cycle system...

Embodiment 2

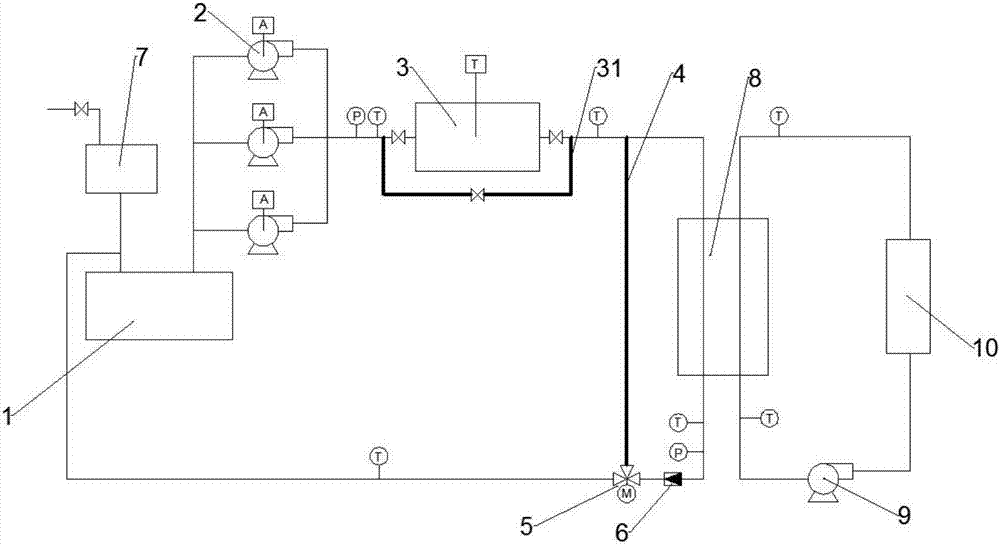

[0059] refer to Figure 2-3 , the heat supply cycle power device 2 has multi-stage output power, and is arranged between the electric boiler 1 and the phase change heat storage heat store 3. The heat supply cycle power device 2 includes at least two heating cycle tubes connected in parallel road pump assembly. This structure can adjust the total power output by the heating cycle power device 2 according to different electricity price periods and external temperature conditions by setting a heating cycle power device 2 with multi-stage output power, and provide cycle power that matches the system demand. Not only is it beneficial to reduce the operating cost of the heating system, but also in the heating process of the electric heating boiler 1, it prevents the boiler from bursting due to untimely circulation and heat accumulation in the electric heating boiler 1.

[0060] At the same time, when any pump assembly in the heating cycle power unit 2 is being maintained, in order ...

Embodiment 3

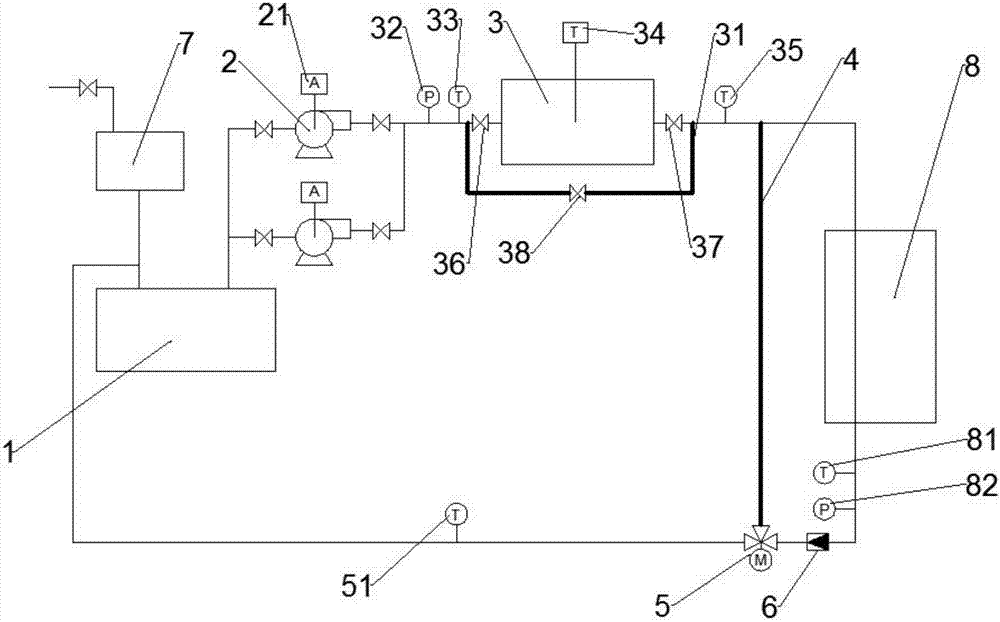

[0066] In order to realize the intelligent control of the entire system, multiple detection devices need to be installed in the system, specifically:

[0067] A heat supply and return water temperature detection device 81, a heat supply and return water pressure detection device 82, and a flow meter 6 are sequentially arranged on the heat supply circulation pipeline between the water outlet of the heat exchange device 8 and the flow divider 5 for measuring the supply and return water pressure. In the heat cycle system, the temperature, pressure and flow of the circulating water after heat exchange by the heat exchange device 8;

[0068] A mixed water temperature detection device 51 is provided on the heat supply circulation pipeline between the splitter regulator 5 and the electric boiler 1, which is used to measure the temperature of the circulating water after heat exchange through the heat exchange device 8 and the circulating water passed through the shunt pipe 4 after mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com