Method for measuring relationship between surveying coordinate system and prism coordinate system of star sensor

A technology for measuring coordinate systems and star sensors. It is used in measurement devices, surveying and navigation, instruments, etc. It can solve the problems of complex on-orbit correction, unclear deviation relationship, and deviation of measurement accuracy, and achieve high reliability and credibility. High degree and high implementability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

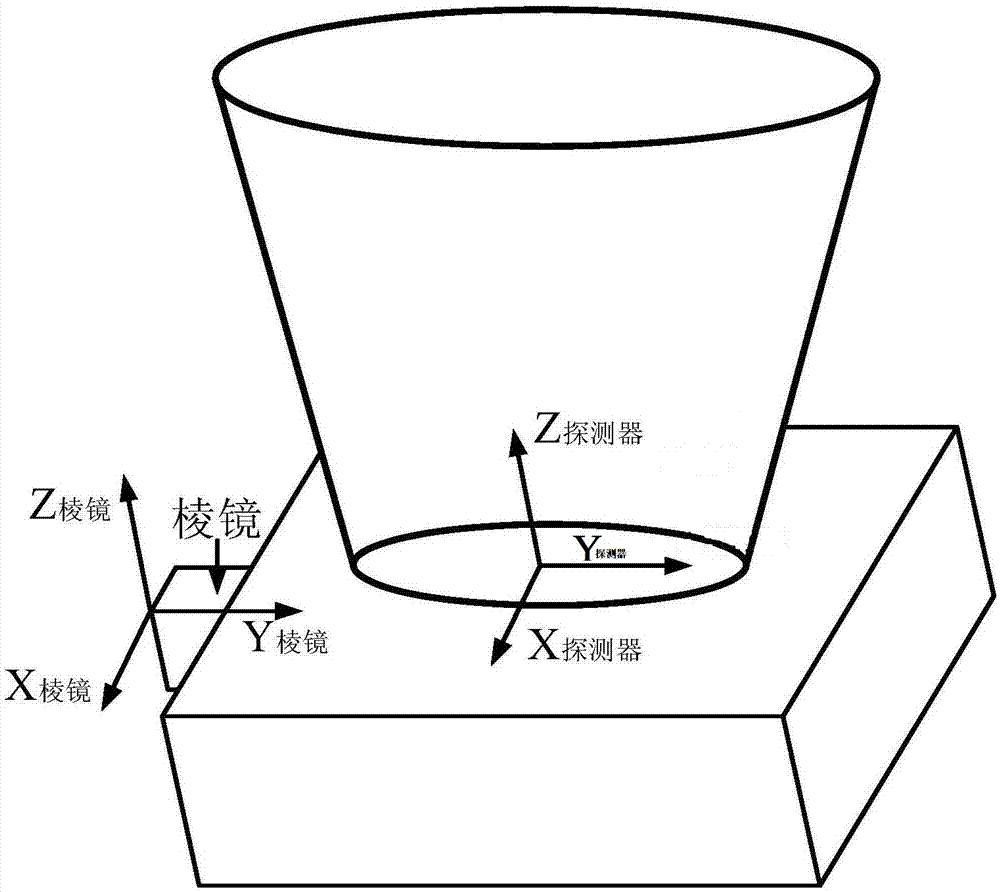

[0033] Such as figure 1 As shown, it is a schematic diagram of the test object of the present invention, and the star sensor includes: a prism, a detector and a housing. o 探测器 is the origin of the measuring coordinate system, X 探测器 is the X axis of the measurement coordinate system, Y 探测器 is the Y axis of the measuring coordinate system, Z 探测器 is the Z axis of the measuring coordinate system, O 棱镜 is the origin of the prism coordinate system, X 棱镜 is the X axis of the prism coordinate system, Y 棱镜 is the Y axis of the prism coordinate system, Z 棱镜 It is the Z axis of the prism coordinate system, and the three axes of the measurement coordinate system and the prism coordinate system point to the same direction, Z 探测器 is the detector optical axis of the star sensor, and the measurement coordinate system and the prism coordinate system of the star sensor satisfy the right-hand rule. The surface of the star sensor installed on the spacecraft or turntable is parallel to X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com