Air tightness test component

A technology for air tightness testing and air tightness detection, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum, and testing of machine/structural components, etc. It can solve the deviation and complexity of test data. Enhancement, decreased work efficiency and other issues, to ensure product quality, accurate parameters, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

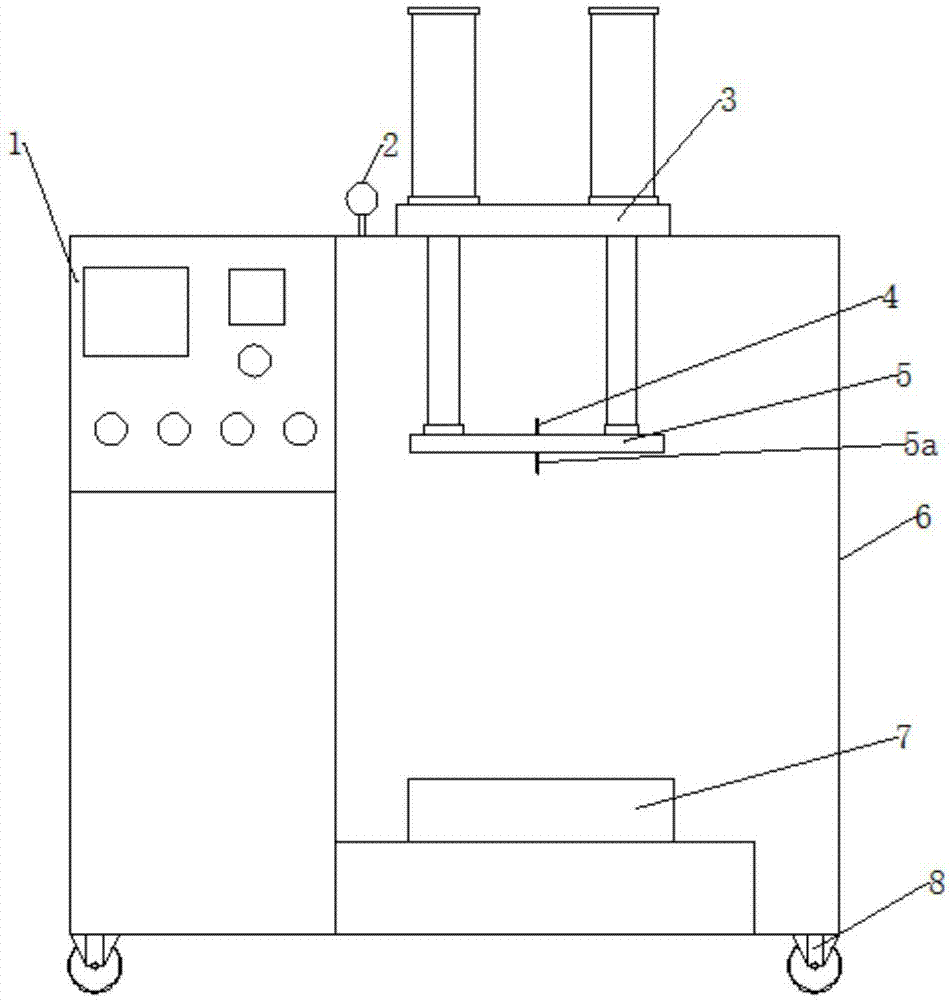

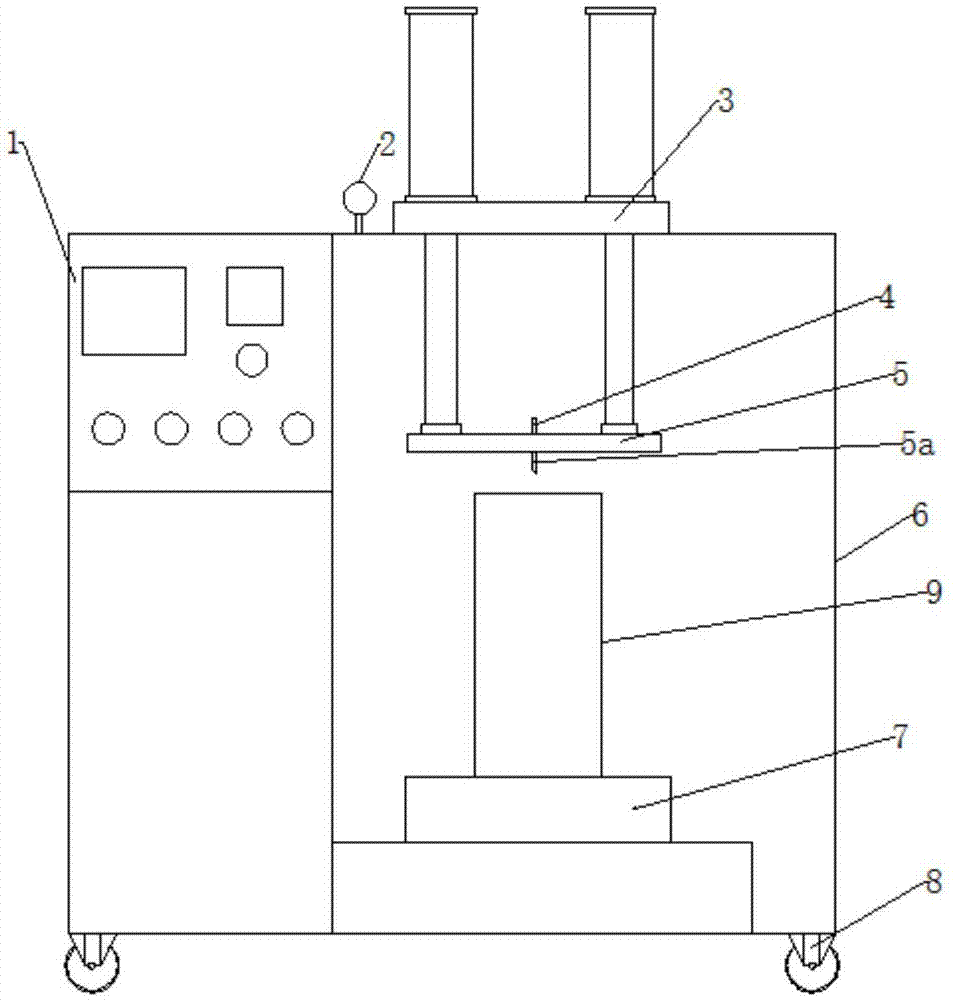

[0016] like figure 1 As shown, an air tightness test assembly includes a control box 1, an operating bracket 6 and an air intake pipe.

[0017] An airtight detection lifting device and a water tank 7 are arranged on the operating support 6 . The airtight detection lifting device comprises a hydraulic air rod 3 and a hollow drill 5, the lower end of the hydraulic air rod 3 is connected with the hollow drill 5, and the hydraulic air rod 3 drives the hollow drill 5 to move in the vertical direction. The lower end of the hollow drill 5 is a hollow cone 5a, and the top of the hollow drill 5 has an air inlet 4, and one end of the air inlet pipe communicates with the air inlet 4, and the other end communicates with the atmosphere. valve. An air inlet is provided on the hollow cone 5a, and an air inlet pipe communicating with the air inlet is provided in the hollow drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com