Multi-jobshop scheduling method and apparatus

A job scheduling and workshop technology, applied in the computer field, can solve problems such as poor convergence ability, low feasibility, easy to fall into local optimum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

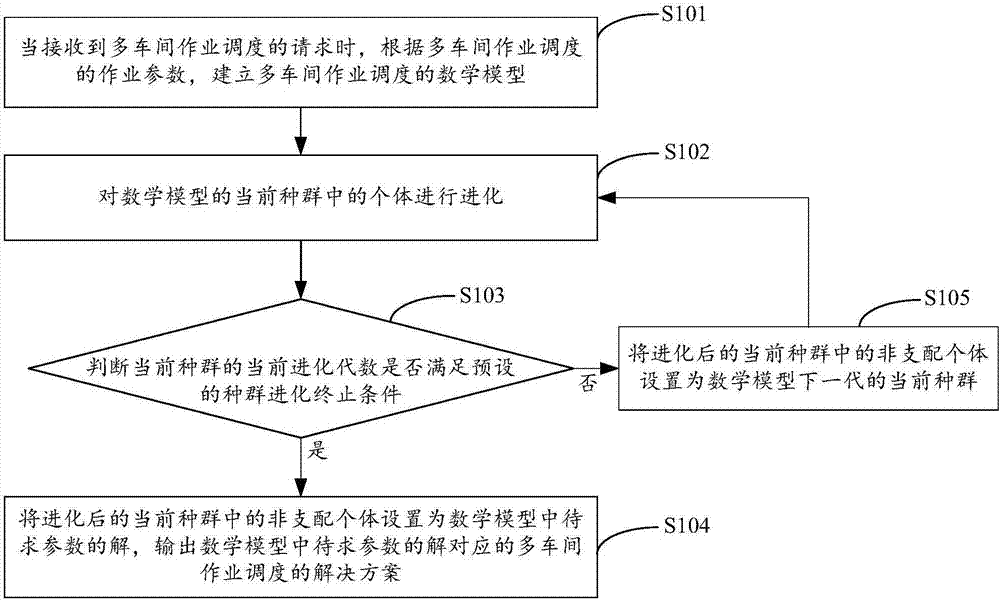

[0028] figure 1 The implementation process of the multi-shop job scheduling method provided by Embodiment 1 of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows:

[0029] In step S101, when a request for multi-job scheduling is received, a mathematical model of multi-job scheduling is established according to job parameters of multi-job scheduling.

[0030] In the embodiment of the present invention, when a request for multi-shop job scheduling is received, the job parameters of the multi-shop job are received for establishing a mathematical model of the multi-shop job scheduling. As an example, the operation parameters of a multi-workshop operation may include the number N of workpieces to be processed, and the number of processes n that each workpiece needs to go through. j , the number M of machines that can be used for processing, and the processin...

Embodiment 2

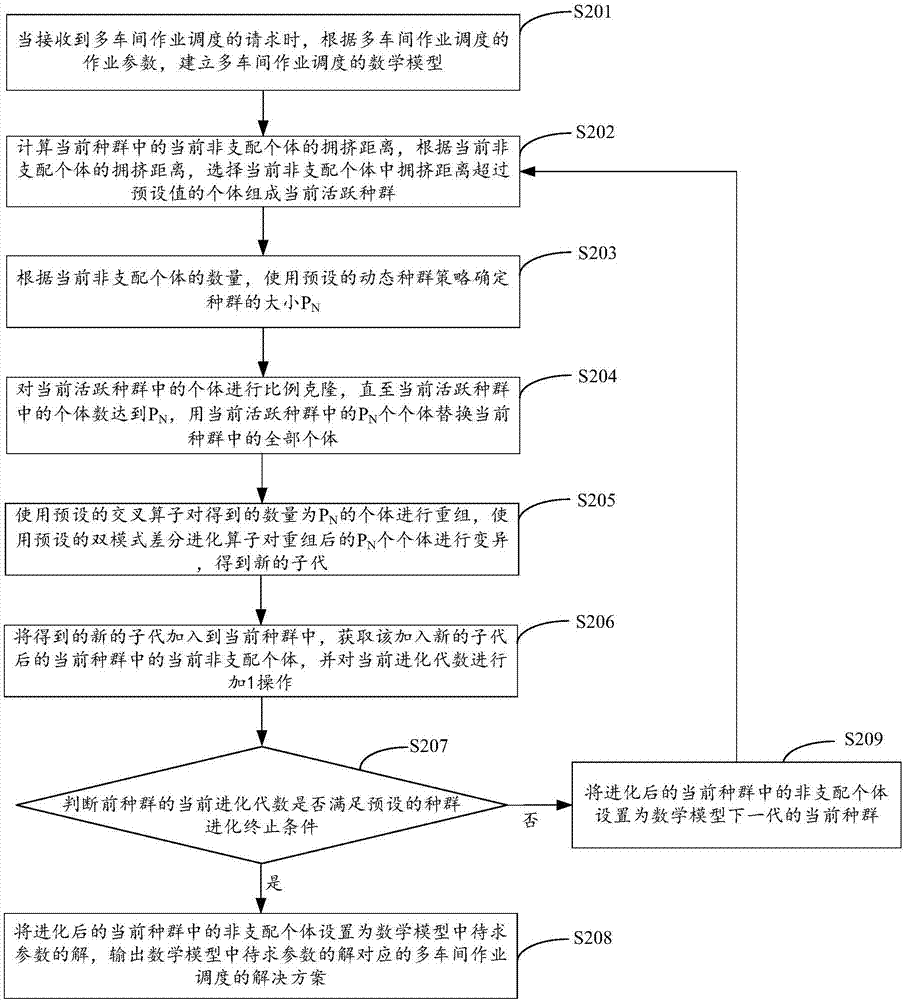

[0041] figure 2 The implementation flow of the multi-shop job scheduling method provided by the second embodiment of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows:

[0042] In step S201, when a request for multi-job scheduling is received, a mathematical model of multi-job scheduling is established according to the job parameters of the multi-job scheduling.

[0043] In step S202, the crowding distance of the current non-dominated individuals in the current population is calculated, and according to the crowding distance of the current non-dominated individuals, individuals among the current non-dominated individuals whose crowding distance exceeds a preset value are selected to form the current active population.

[0044] In the embodiment of the present invention, the crowding distance of the current non-dominated individuals in the current popul...

Embodiment 3

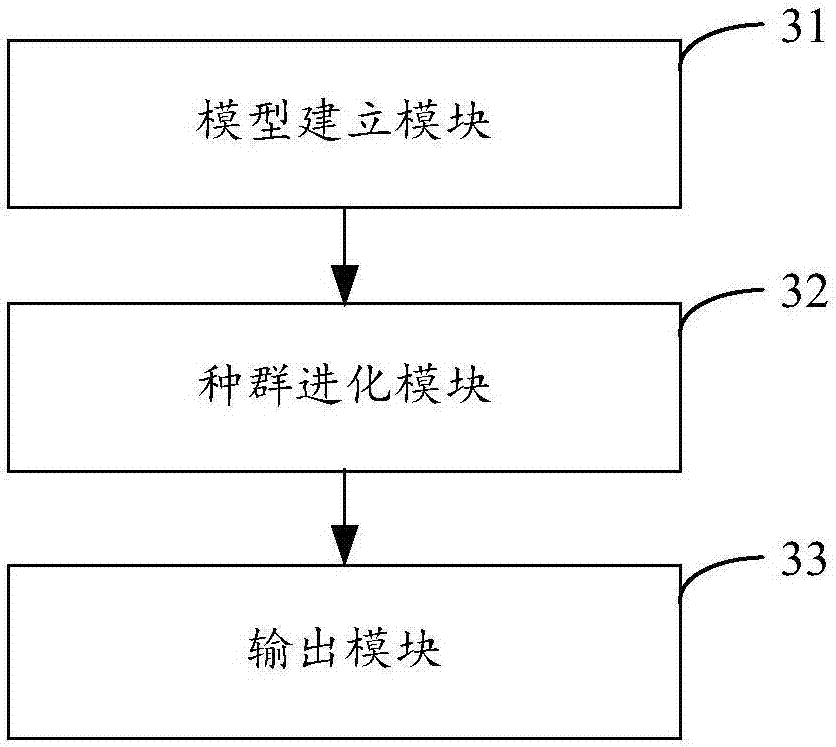

[0060] image 3 The structure of the multi-shop job scheduling device provided by the third embodiment of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown, including:

[0061] The model building module 31 is configured to establish a mathematical model of multi-shop job scheduling according to the job parameters of multi-shop job scheduling when receiving a request for multi-shop job scheduling.

[0062] In the embodiment of the present invention, when a request for multi-shop job scheduling is received, the model building module receives job parameters of the multi-shop job for establishing a mathematical model of the multi-shop job scheduling. As an example, the operation parameters of a multi-workshop operation may include the number N of workpieces to be processed, and the number of processes n that each workpiece needs to go through. j , the number M of machines that can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com