Variable-stiffness flexible bionic fish model based on internal fluid pressure adjustment

A fluid pressure and variable stiffness technology, applied in the field of underwater bionic robots, can solve problems such as large turning radius, lower propulsion efficiency than real fish, and adjustment of fish tail stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

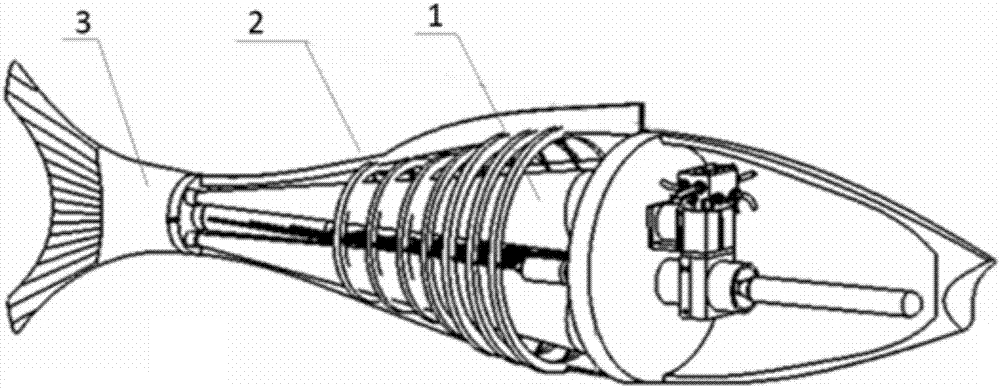

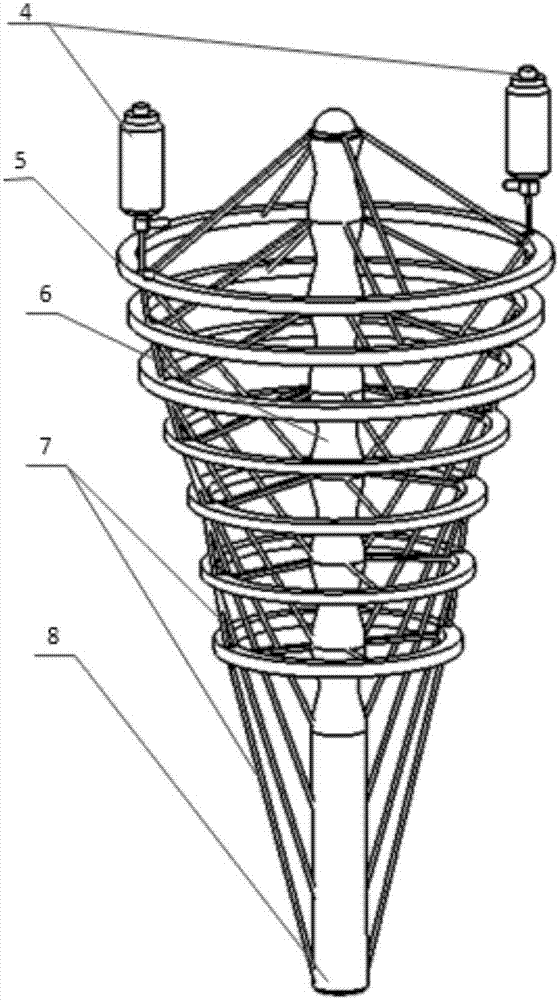

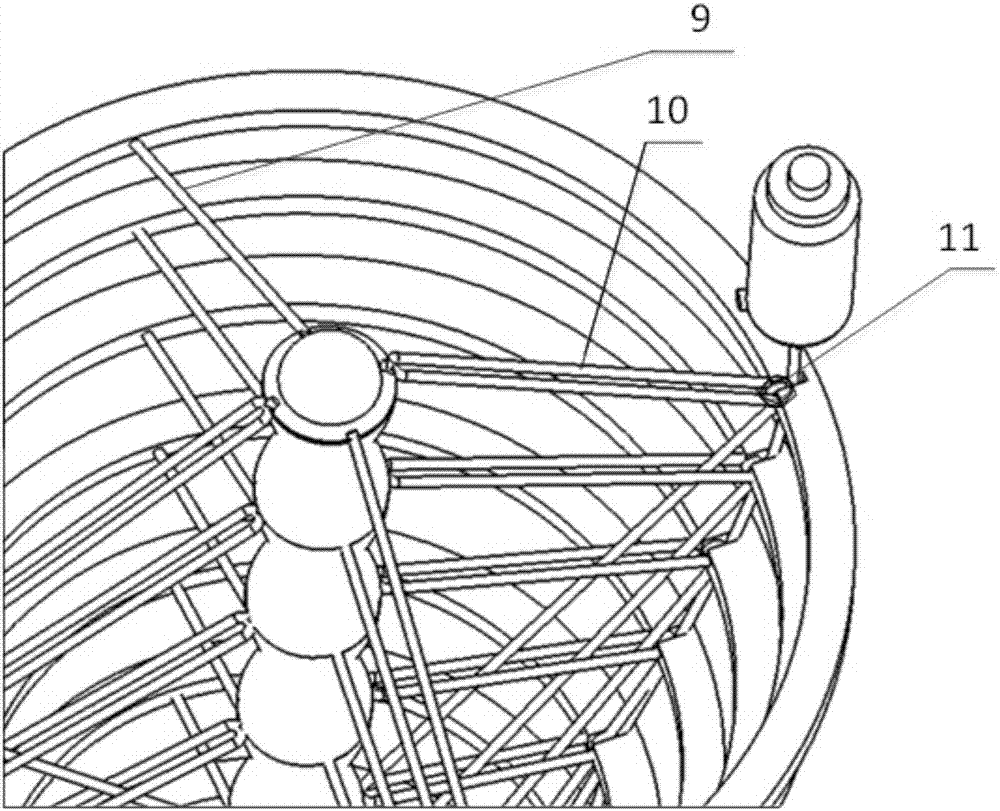

[0021] Such as Figure 1-4 As shown, a flexible bionic fish model with variable stiffness based on internal fluid pressure adjustment, including fish head, fish body 2 and caudal fin 3, the fish head and fish body are wrapped with skin, and the fish head is equipped with aerodynamic power Control unit; the fish body includes four internal conical pneumatic muscles 1 and nested series-parallel units, the nested series-parallel units serve as the spine and skeleton of the bionic fish, and the four internal conical pneumatic muscles 1 are respectively located in the nested Inside the series-parallel unit, the front end of each internal conical aerodynamic muscle 1 is connected to the fish head, and its end is connected to the tail fin through a rigid fixture. The aerodynamic power control unit is connected to the nested series-parallel unit and four internal conical muscles The pneumatic muscle is connected, and the pneumatic power control unit realizes the swing and twist of the...

Embodiment 2

[0028] Such as figure 1 , 4 Shown, present embodiment comprises three parts of fish head, fish body and tail. The fish body is the main moving part. The tail, as the end effector, is a crescent piece made of hard plastic, and the selection of geometric parameters is as close as possible to the size of the tail fin of a fish in reality. One end of the rigid fixture 12 is connected with the conical pneumatic muscle 1 , and the other end of the rigid fixture 12 is connected with the crescent-shaped plastic plate 3 .

[0029] Such as Figure 5-7 As shown, there is a pneumatic power control unit in the head of the fish, which is used as the power source of the whole fish, including power supply, suction pipe, diverter, air pipe, exhaust valve, proportional control valve, mechanical calibrator, and air storage tank. The structure refers to the arrangement of pneumatic components of robotic fish in the article "Autonomous Soft Robotic Fish Capable of Escape Maneuvers Using Fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com