Double-station separation mold for high-density pin integrated circuit and its usage

An integrated circuit and double-station technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as pin circuit failure and pin deformation, and achieve the effect of avoiding insufficient strength and meeting strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

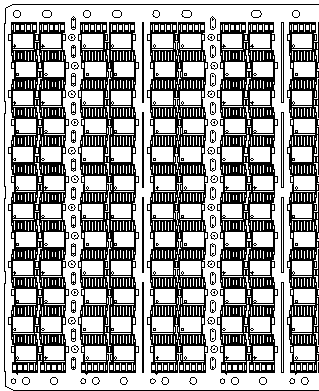

Image

Examples

Embodiment Construction

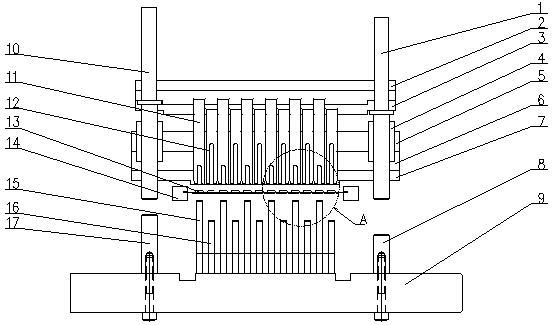

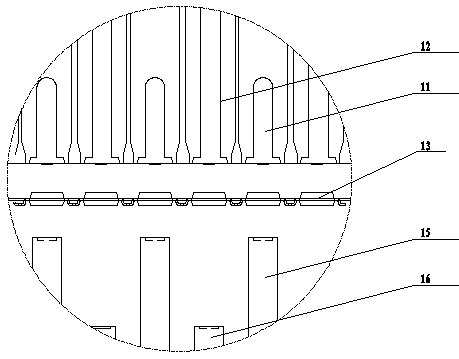

[0015] The present invention will be further described below in conjunction with the drawings.

[0016] Such as figure 2 , image 3 As shown, the dual-station separation mold for high-density pin integrated circuits includes an upper female mold assembly and a lower male mold assembly. The lower male mold assembly includes a lower male mold base 9 and a fixed connection respectively. The first separation station limit post 17 and the second separation station limit post 8 at both ends of the lower punch base, the first separation station limit post is higher than the second separation station limit post, the In the middle of the lower punch base, there are first separating punches 15 and second separating punches 16 alternately distributed along the horizontal direction, and the height of the first separating punches is higher than that of the second separating punches; the upper concave die set The parts include an upper die base 7 and a first vertical guide rod 10 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com