Integrated RGB-LED display

A technology of RGB-LED and display screen, which is applied in the direction of identification devices, instruments, semiconductor devices, etc. It can solve the problems of poor mechanical strength, poor heat dissipation performance, and low production efficiency of RGB LED display screens, and achieve short heat dissipation paths and enhanced electrical conductivity. Performance, the effect of improving the ability to resist external mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

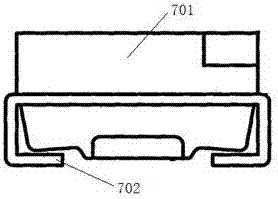

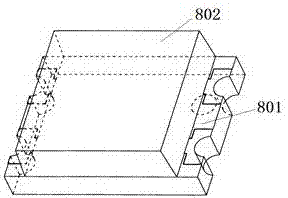

[0034] figure 1 It is a schematic diagram of the structure of the existing PPA+copper pin package bracket. Since this type of package bracket uses the injection molding machine to attach the thermoplastic material to the metal, there is no sticking together. When thermal expansion and cold contraction, it is easy to A gap is generated, and when the end customer is using it, external water and water vapor can easily enter the package through the gap, causing product failure. figure 2 It is a schematic diagram of the structure of the existing CHIP type packaging bracket. It is formed by surrounding and compacting the glass fiber with resin 801, and then dipping copper and platinum etching lines. The gap and moisture absorption rate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com