A LED packaging method based on phosphor powder uniform coating

A technology of LED packaging and phosphor powder, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult mixing of phosphor powder and packaging glue, wide range of particle sizes, inconsistent particle sizes of phosphor powder, etc., to reduce Equipment requirements and operation difficulty, improving the economic benefits of the enterprise, and improving the effect of particle size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

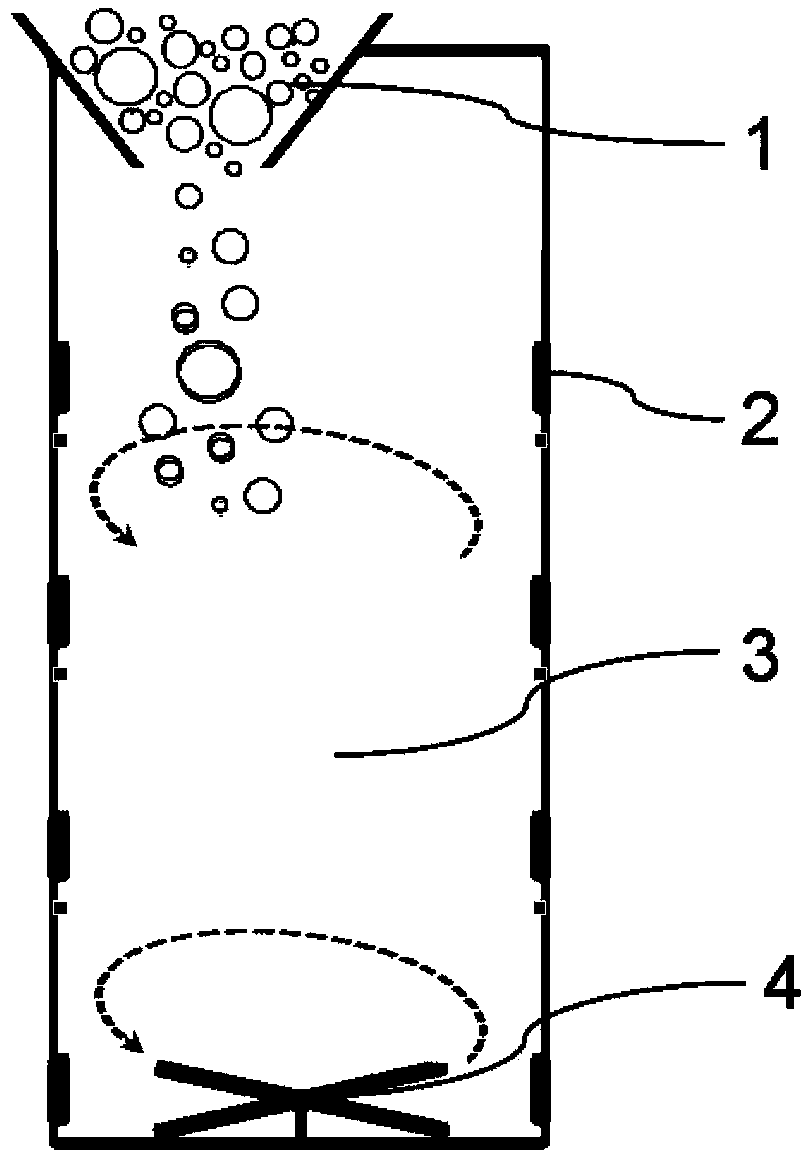

[0044] Embodiment 1 This embodiment discloses a LED packaging method based on uniform coating of phosphor powder (for details, see Figure 1-11 shown), the process steps of the method are as follows:

[0045] 1) Firstly, phosphor powder is screened by a particle size screening device for phosphor powder. A feeding port 1 is provided on the top of the screening device, and an accommodating chamber 3 filled with a dispersion solution is provided inside the device. The feeding port 2 Connected with the accommodating chamber 3, a stirring rotor 4 is provided at the bottom of the accommodating chamber 2; at least one receiving partition 5 is arranged on the outer wall of the device; the receiving partition 5 is connected with the accommodating chamber The bottom of 3 is parallel.

[0046] According to the different falling speeds of phosphors with different particle sizes (weights) in the dispersion liquid, the solution mixed with phosphors is isolated according to the height, so ...

Embodiment 2

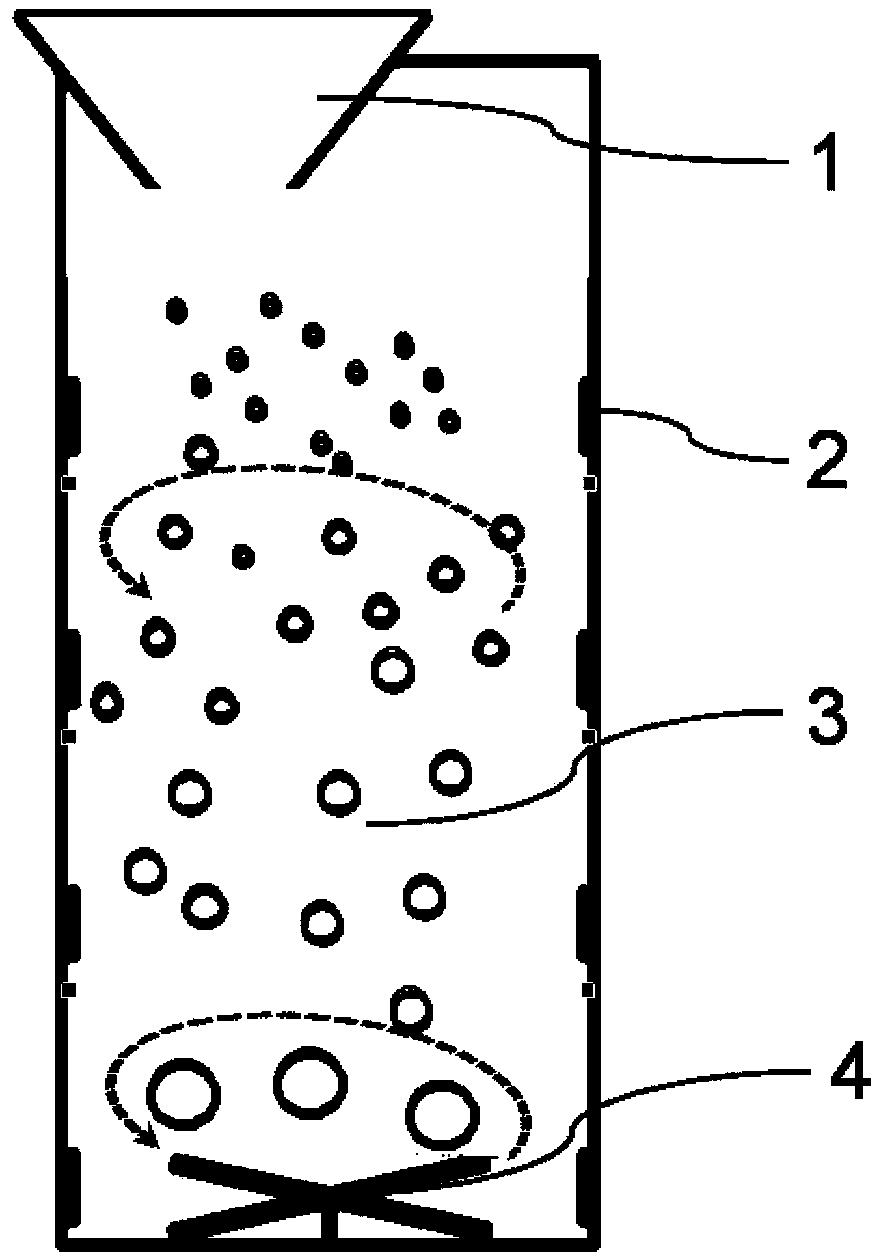

[0059] Embodiment 2 This embodiment discloses a LED packaging method based on phosphor powder uniform coating, and the process steps of the method are as follows:

[0060] 1) Firstly, phosphor powder is screened by a particle size screening device for phosphor powder. A feeding port 1 is provided on the top of the screening device, and an accommodating chamber 3 filled with a dispersion solution is provided inside the device. The feeding port 2 Connected with the accommodating chamber 3, a stirring rotor 4 is provided at the bottom of the accommodating chamber 2; at least one receiving partition 5 is arranged on the outer wall of the device; the receiving partition 5 is connected with the accommodating chamber The bottom of 3 is parallel.

[0061] According to the different falling speeds of phosphors with different particle sizes (weights) in the dispersion liquid, the solution mixed with phosphors is isolated according to the height, so as to realize the screening of the par...

Embodiment 3

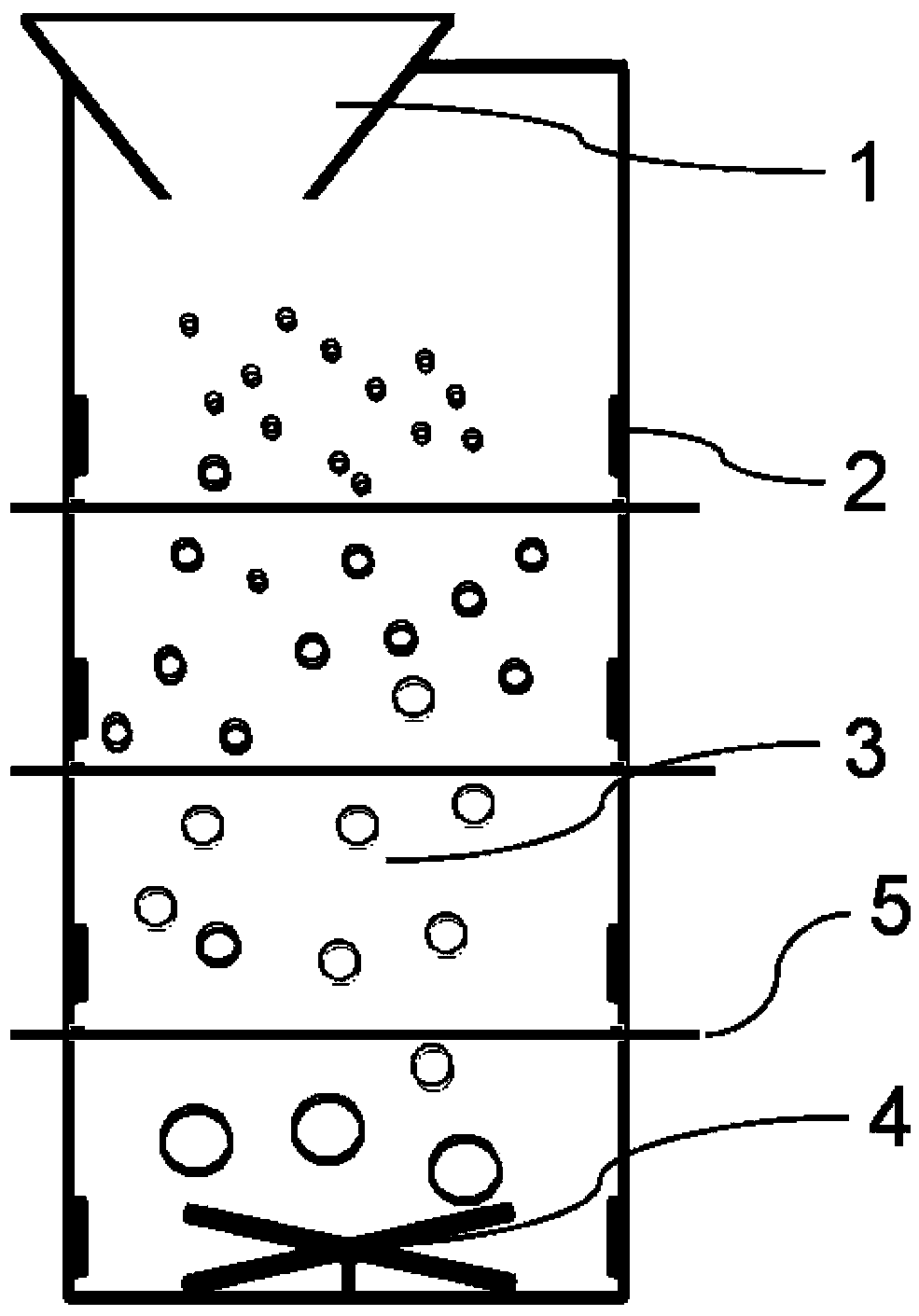

[0074] Embodiment 3 This embodiment discloses a LED packaging method based on phosphor powder uniform coating, and the process steps of the method are as follows:

[0075] 1) A liquid-phase fluorescent powder particle size screening device, including a feed inlet, a drying vent, a dispersion solution, a stirring rotor, and a receiving partition. The stirring rotor is placed in the dispersion solution, and each drying vent is With socket. According to the different falling speeds of phosphors with different particle sizes (weights) in the dispersion liquid, the solution mixed with phosphors is isolated according to the height, so as to realize the screening of the particle size of phosphors. The dispersion solution is an inorganic and organic solution of water, dichlorobenzene, and ethylene glycol monomethyl ether, and the number of drying vents is 13.

[0076] 2) Inject an appropriate amount of dispersion solution into the sieving device, and then take an appropriate amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com