Iron chromium aluminum low electromagnetic radiation heating structure

An electromagnetic radiation, iron-chromium-aluminum technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low service life and fast power attenuation, and achieve the effect of long service life and small power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

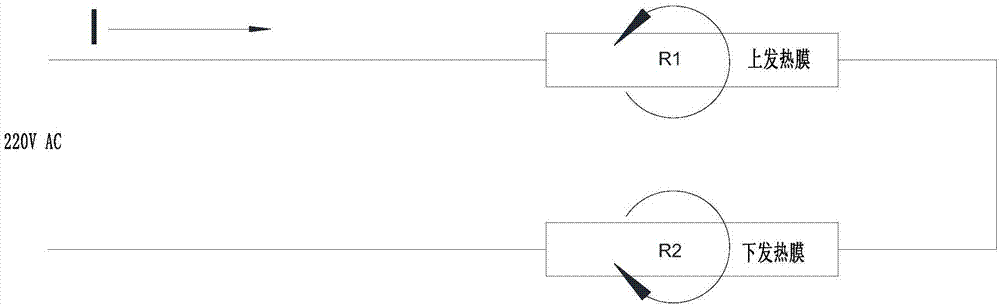

[0017] Such as figure 1 As shown, the iron-chromium-aluminum low electromagnetic radiation heating structure of the present invention includes an electric heating film 500X300-800W / 220VAC, and also includes two heating units. The heating unit includes two mirror-attached electric heating films, and the two electric heating films The circuit structures are mirror images of each other. The two electrothermal films bonded in mirror image are connected in anti-serial connection. Two mirror-fitted electric heating films are connected in reverse series, that is, assuming that the electric heating film has two interfaces, A and B, respectively connected to the positive and negative poles of the power supply. The film B port is connected to the positive pole, so that the currents of the two electrothermal films go in opposite directions, and the generated magnetic fields will also cancel. The electrothermal film adopts iron-chromium-aluminum electrothermal film. FeCrAl is currently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com