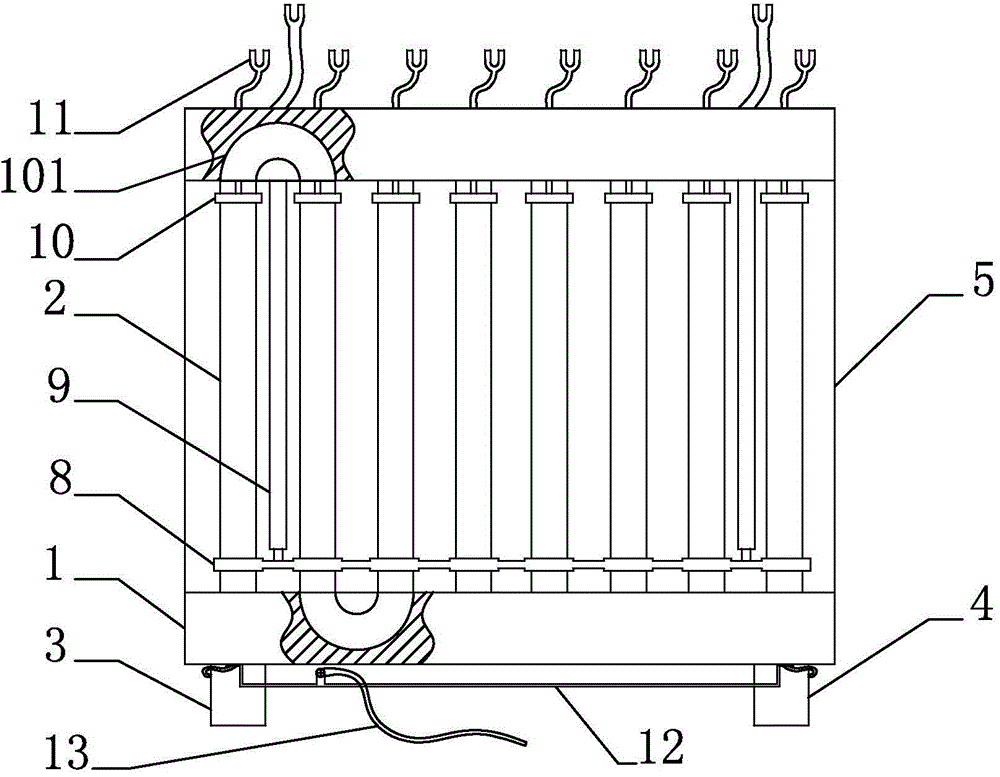

Water tank

A water tank and tank body technology, applied in the field of energy-saving heating, can solve problems such as heat loss, low heat utilization rate, and impact on user health, and achieve the effects of prolonging service life, improving thermal efficiency, and reducing power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

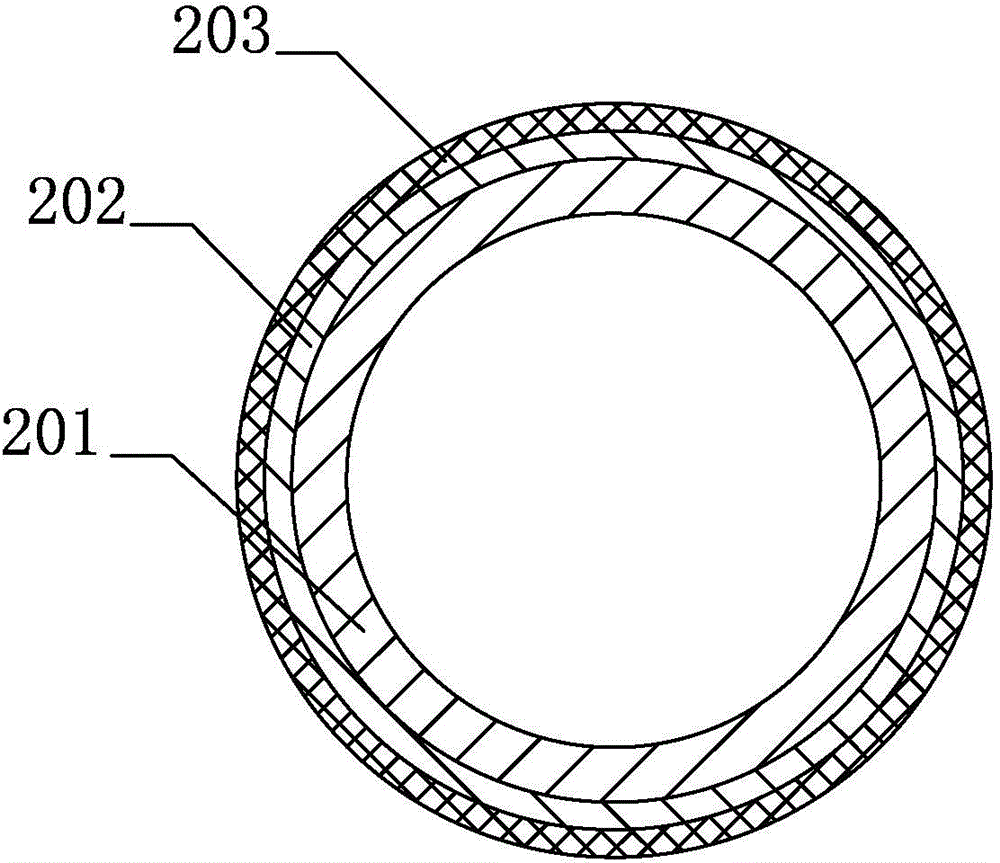

[0020] Example 1, the percentage by weight of each component in the formula of the electrothermal film solution is 41% of tin tetrachloride, 54.5% of alcohol, 0.9% of antimony trichloride, 0.1% of rare earth element, 0.9% of ferric chloride, absolute ethanol 1.8%, titanium tetrachloride 0.75%, boric acid 0.05%.

Embodiment 2

[0021] Example 2, the percentage by weight of each component in the formula of the electrothermal film solution is 44.5% of tin tetrachloride, 51% of alcohol, 0.7% of antimony trichloride, 0.08% of rare earth element, 0.75% of ferric chloride, absolute ethanol 2%, titanium tetrachloride 0.9%, boric acid 0.07%.

Embodiment 3

[0022] Example 3, the percentage by weight of each component in the formula of the electrothermal film solution is 43% of tin tetrachloride, 53% of alcohol, 0.6% of antimony trichloride, 0.09% of rare earth element, 0.6% of ferric chloride, absolute ethanol 1.95%, titanium tetrachloride 0.7%, boric acid 0.06%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com