Constant-temperature co-fired ceramic heating base plate and preparation method thereof

A technology of ceramic substrates and co-fired ceramics, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of burning components or auxiliary devices, unstable product performance, etc., and achieve long service life, simple structure, and high temperature. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

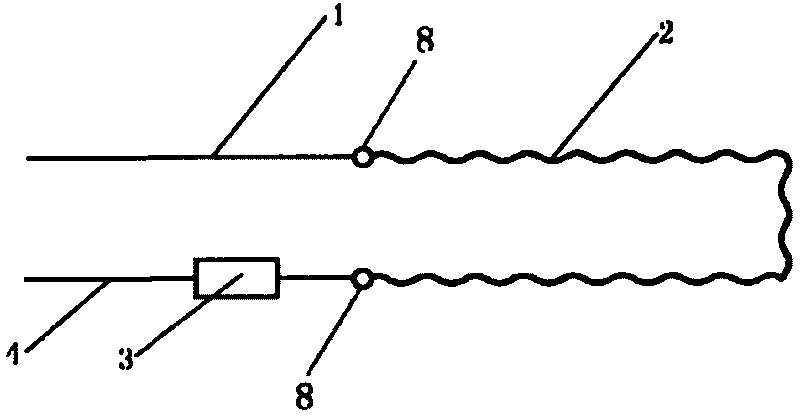

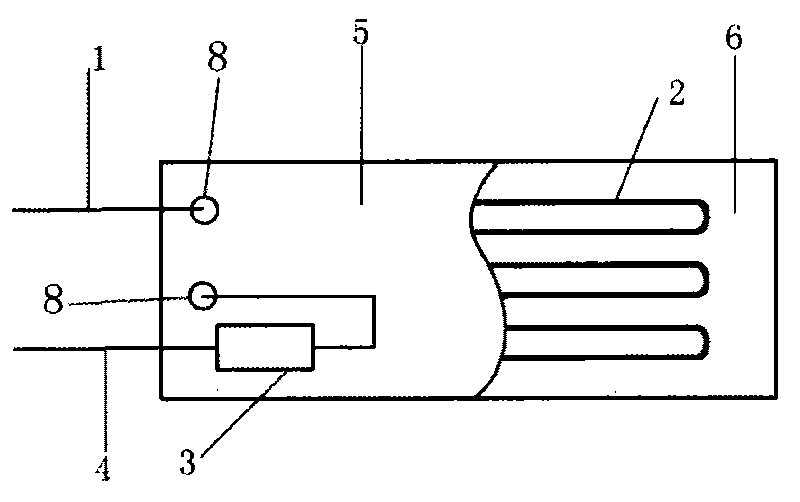

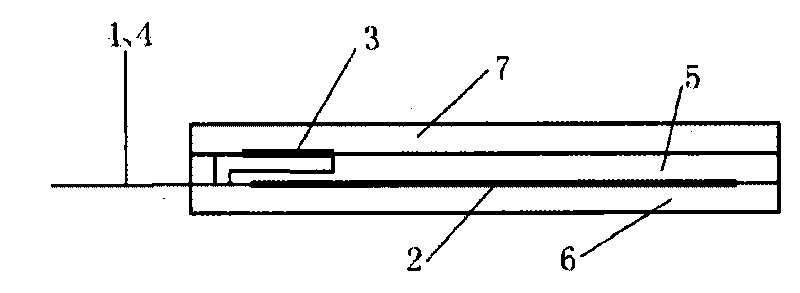

[0020] Such as figure 1 , 2 , 3, the constant temperature fired ceramic heating substrate and the preparation method thereof according to the present invention are characterized in that: the constant temperature co-fired ceramic heating substrate comprises two or three laminated ceramic substrates 5, 6 or 7, 5, 6. The ceramic substrates 7, 5, and 6 are carriers, and the laminated layer is packaged with a resistance heating circuit board 2 printed with resistance paste;

[0021] The laminated layer of the ceramic heating substrates 5 and 7 is packaged with a constant temperature resistance plate 3 printed with a constant temperature resistance paste; the two ends of the resistance heating circuit board 2 are respectively welded with silver and copper sheets 8, and the silver and copper sheets at one end are Metal leads 1 are directly brazed on 8; metal leads 4 are brazed on the silver copper sheet 8 at the other end, and constant temperature resistance plates 3 are connected b...

Embodiment 2

[0022] Embodiment two: if figure 1 , 4 , as shown, ( Figure 4 The ceramic substrate 5 is not shown in the figure), the ceramic substrate 5 or 6 is used as the carrier, and the resistance heating circuit board 2 and the constant temperature resistance board 3 are printed on one side of the carrier, and the two ends of the resistance heating circuit board 2 are respectively connected to the silver copper sheet 8 Among them, the silver-copper sheet 8 at one end is directly welded with a metal lead 1, and the metal lead 4 welded on the silver-copper sheet 8 at the other end is connected to the two ends of the constant temperature resistance plate 3, and the ceramic substrate 6 and the ceramic substrate 5 are stacked. Press-packed resistance heating wire version 2, constant temperature resistance version 3.

[0023] Of course, the above-mentioned embodiment is a preferred solution, if one end of the resistance heating circuit board 2 printed on the carrier is welded with silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com