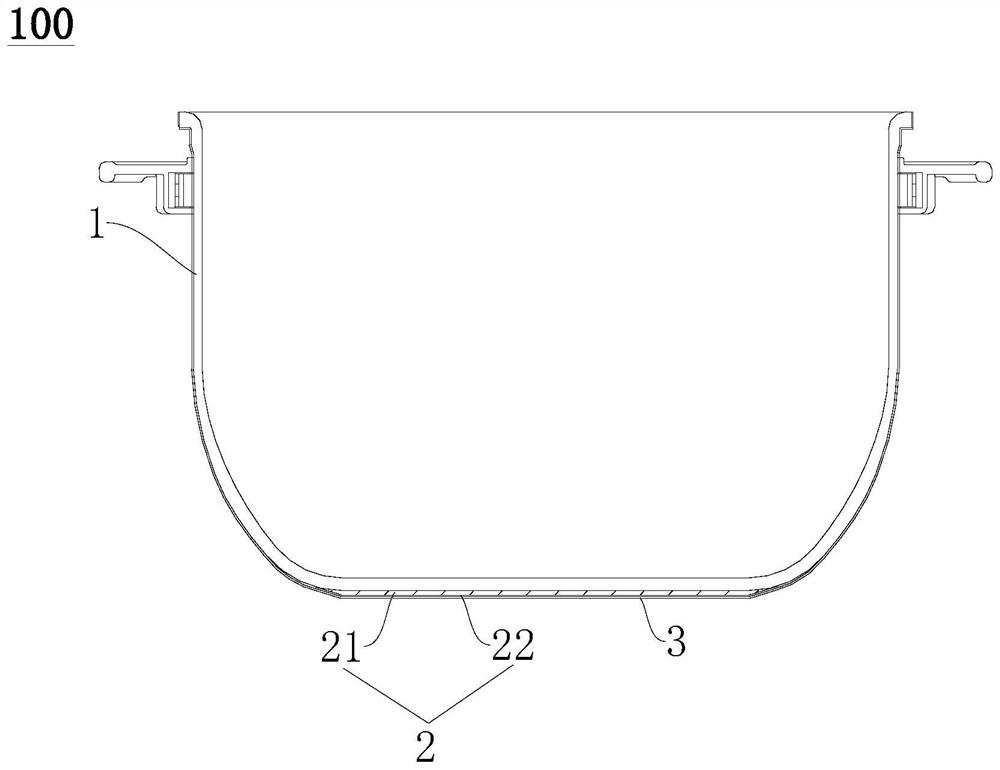

Container, cooking utensil and manufacturing method of container

A manufacturing method and container technology, which is applied in the manufacture of cooking utensils and containers, and in the field of containers, can solve the problems of container heating power attenuation, heat loss, and high heating noise, and achieve small power attenuation, less heat loss, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

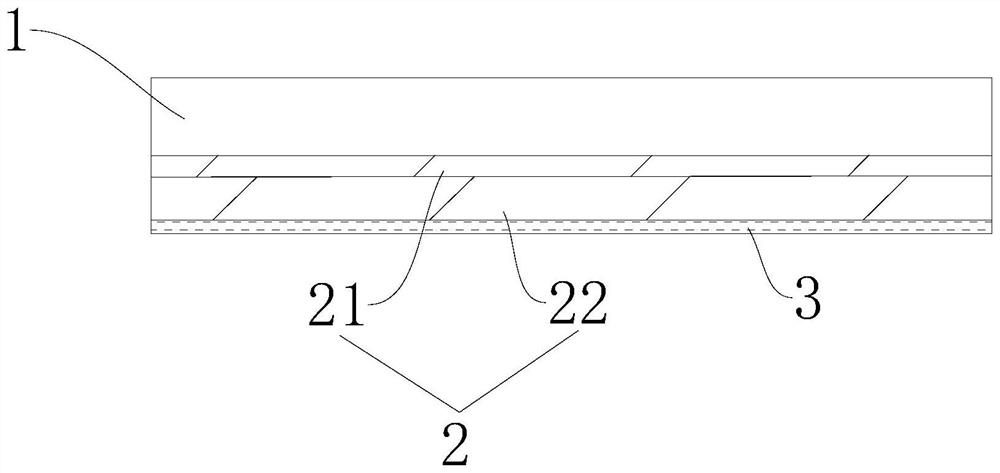

[0087] Step 1, the body 1 is formed by press molding, degreasing treatment, and outer surface sand blasting;

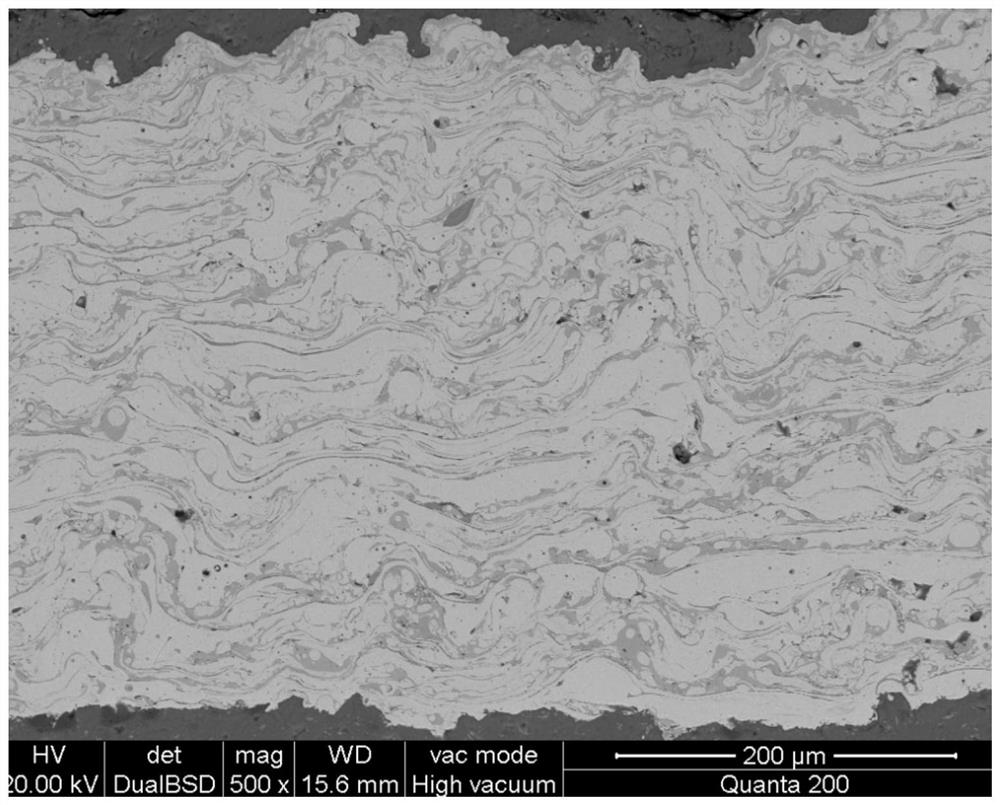

[0088] Step 2, using a cold spray process to spray the first conductive magnetic layer 21 in the outer surface of the body 1, the raw material of the first conductivity magnetic layer 21 is purged with a purity of 99%, the cold spray process parameters are: the spray gun temperature 850 ° C, adopts Nitrogen gas is used as a working gas and the nitrogen pressure is 4 MPa, the spray distance is 20 mm, the powder distribution rate is 100 g / min, the spray angle is 90 °, and the first conductivity magnetic layer 21 having a thickness of 300um is prepared;

[0089] Step three, using the arc spray process to spray the second conductivity magnetic layer 22 on the surface of the first conductive magnetic layer 21, the raw material of the second conductivity magnetic layer 22 uses a ferrome alloy wire, the spray process parameters are: spray pressure 0.6MPa, spray distance 200mm,...

Embodiment 2

[0093] Step 1, the body 1 is formed by press molding, degreasing treatment, and outer surface sand blasting;

[0094] Step 2, using a cold spray process to spray the first conductive magnetic layer 21 in the outer surface of the body 1, the first conductivity magnetic layer 21 raw material is purified from 99%, the cold spray process parameters are: spray coating temperature 900 ° C, nitrogen As the working gas and the nitrogen pressure 4.5MPa, the spray distance is 15mm, the powder distribution rate is 150 g / min, the spray angle is 92 °, the first conductivity magnetic layer 21 having a thickness of 200 um is prepared;

[0095] Step three, using a cold spray process to spray the second conductive magnetic layer 22 on the surface of the first conductive magnetic layer 21, the second conductivity magnetic layer 22 raw material is purged with a purity of 99%, the cold spray process parameter pressure is: the gun temperature 600 At ° C, air is used as a protective gas and the air p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com