Fully-automatic FOG bonding machine Teflon plate clamping mechanism

A clamping mechanism and binding machine technology, applied in optics, instruments, electrical components, etc., to save adjustment time, ensure continuity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

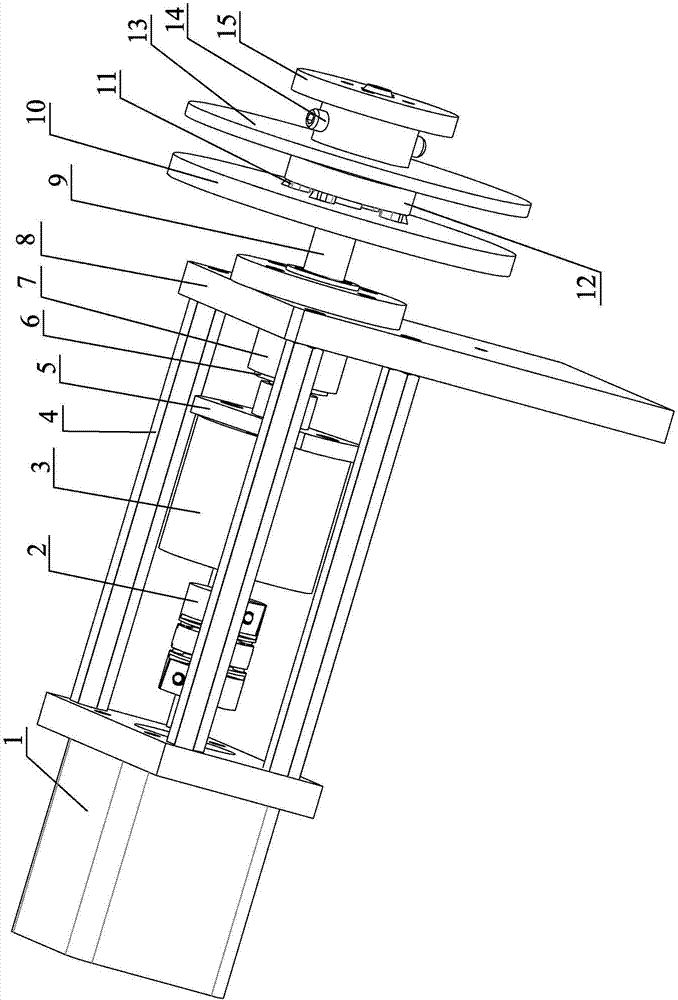

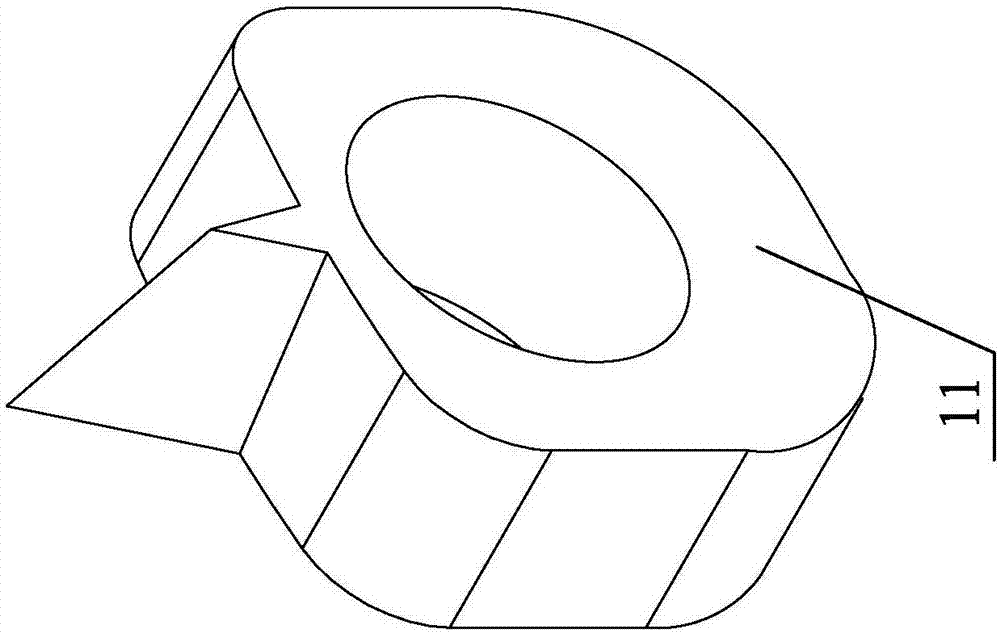

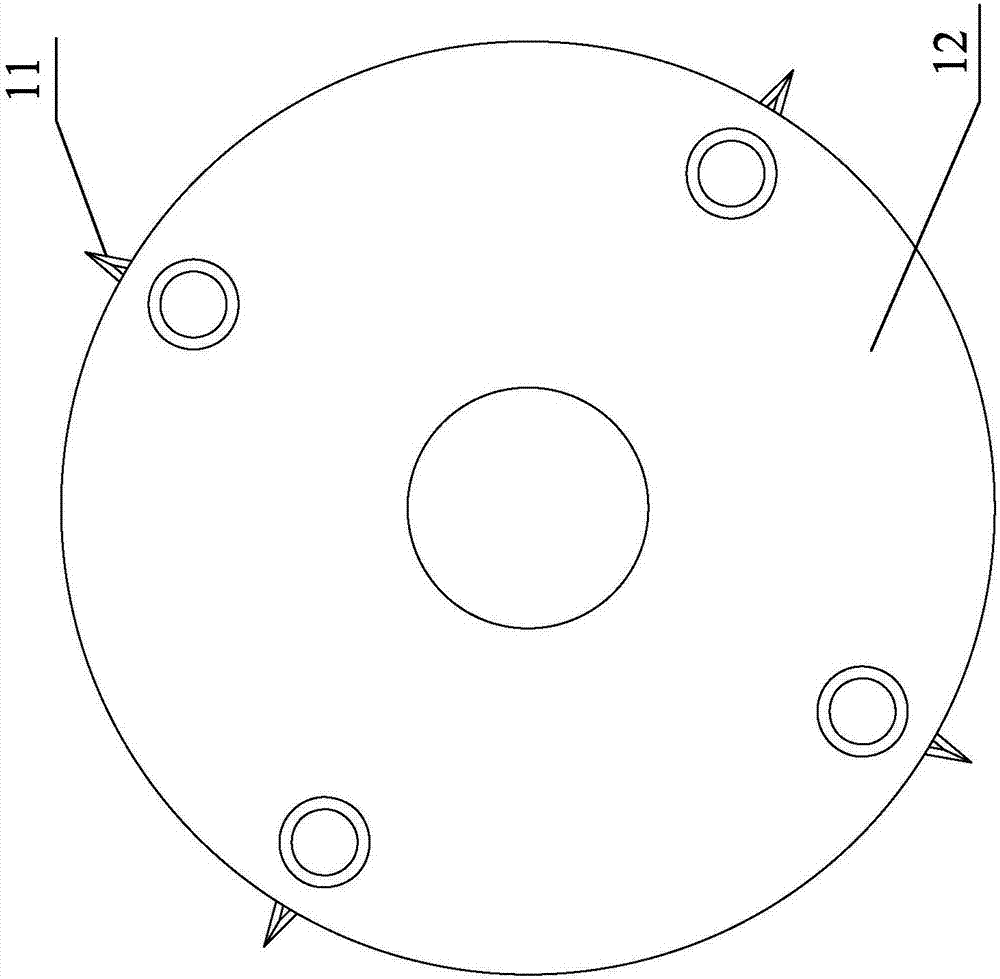

[0013] The invention discloses a Teflon material tray clamping mechanism for a fully automatic FOG binding machine. The structural components include a motor 1, a shaft coupling 2, a damper 3, a hexagonal column 4, a damper mounting plate 5, a bearing 6, and a bearing Mounting part 7, support plate 8, rotating shaft 9, rear material tray baffle plate 10, clamping material tray part 11, material tray guide 12, front material tray baffle plate 13, ball plunger 14, hand clasp 15.

[0014] Such as figure 1 As shown, the motor 1 drives the coupling 2, and transmits the rotation to the front damper mounting plate 5 through the damper 3, and the damper mounting plate 5 transmits the rotation to the rotating shaft 9 through the top screw, passing through the bearing 6 and the bearing mounting part 7 And the support of the support plate 8 enables the whole mechanism to be installed in a suitable position so that the overall structure can operate normally. Install the rear tray baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com