A method for self-adaptive calibration of anesthesia machine ip valve

An anesthesia machine and self-adaptive technology, applied in the field of anesthesia machines, can solve the problem of not being able to automatically adapt to the electrical characteristics of different IP valves, and achieve the effect of accurate and reliable calibration, avoiding uncertainty, and improving the degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described now in conjunction with accompanying drawing.

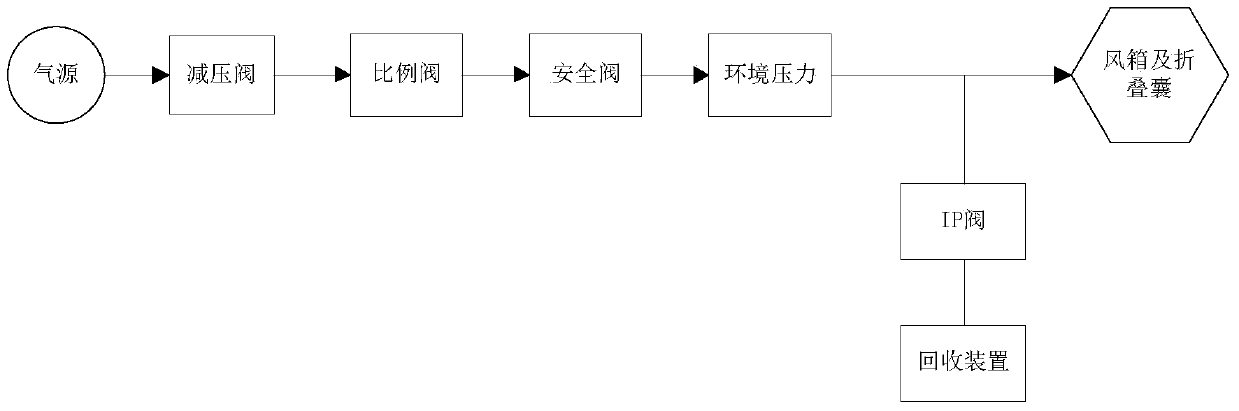

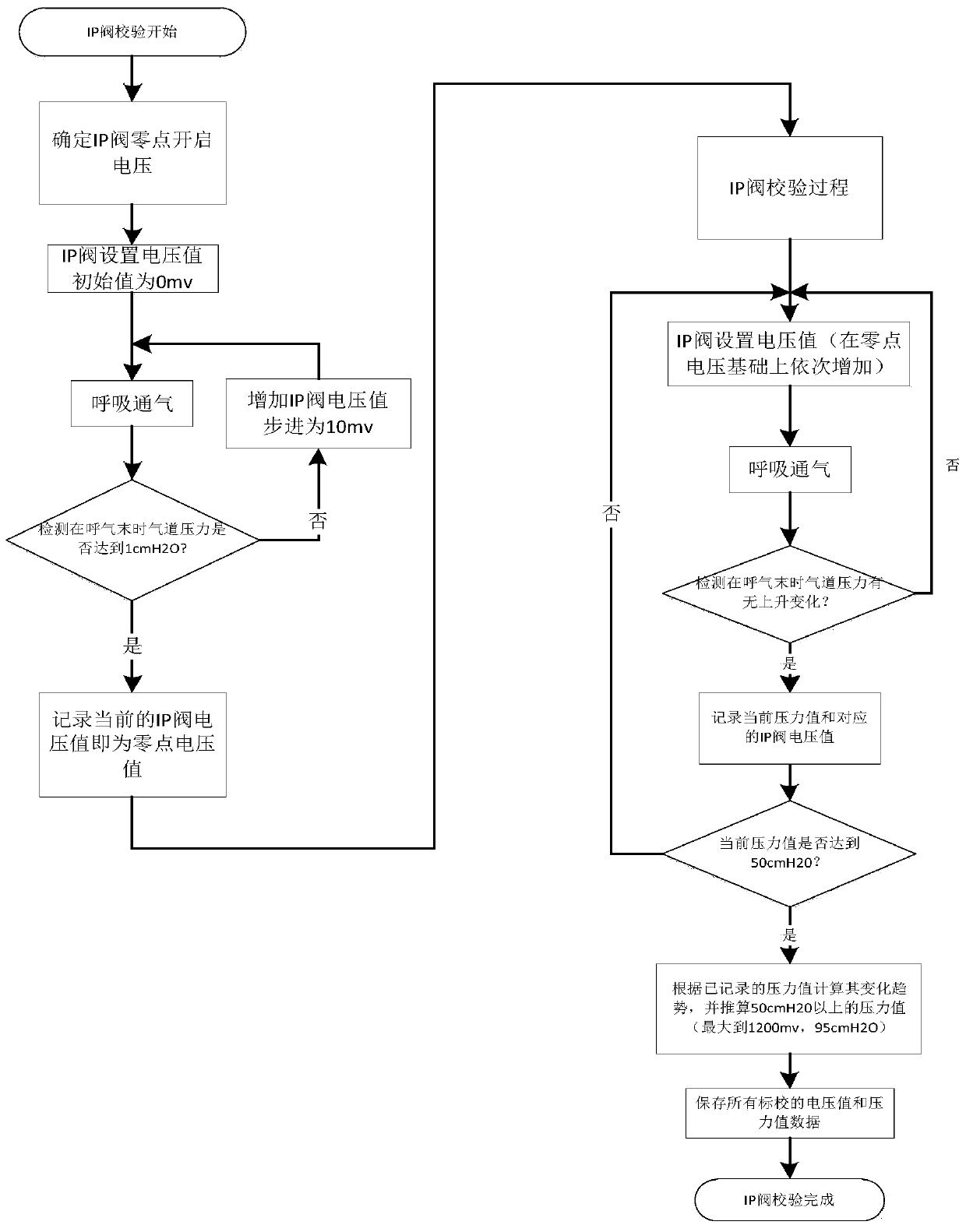

[0028] figure 1 The position and function of the IP valve in the anesthesia machine system are shown. When the anesthesia machine is working, when the gas from the gas source enters the bellows folding bag through the pressure reducing valve, proportional valve, safety valve and other components, a certain airway pressure will be generated, and the IP valve will play a certain role in the airway pressure. restrictions and adjustments. The purpose of calibrating the IP valve is to ensure that it can adjust the pressure accurately and effectively, that is, how much pressure the IP valve wants to control, and how much voltage will be passed to it. The control pressure and corresponding voltage value of the IP valve are determined when the IP valve is calibrated. The control pressure and voltage value can form a data relationship curve between the control pressure and voltage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com