Tangential introducing spiral-flow type gas-liquid mixing efficient atomization nozzle

A gas-liquid mixing and atomizing nozzle technology, which is applied in the field of gas-liquid mass transfer, can solve the problems of insufficient mixing of gas and liquid, miniaturization of atomized particles, and reduced work efficiency, etc., so as to improve the atomization effect and prevent gas Good effect of leakage and atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

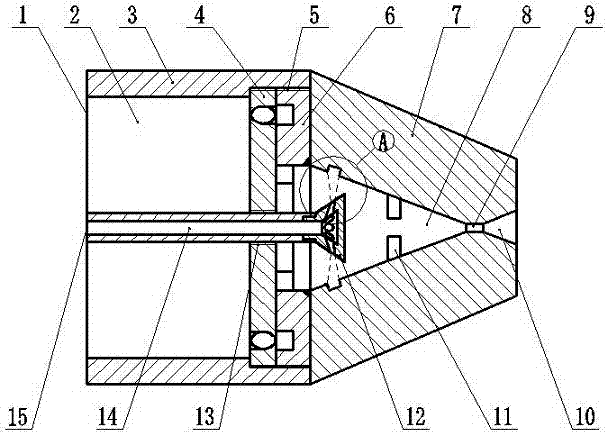

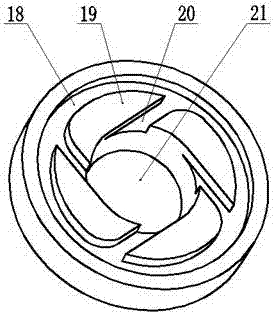

[0028] figure 1 It shows a structure of tangentially introducing swirl type gas-liquid mixing high-efficiency atomizing nozzle. A tangentially introduced swirl type gas-liquid mixing high-efficiency atomizing nozzle, including a feed chamber 3, a swirl chamber 6, and a spray head 7. The feed chamber 3 includes a gas channel 14, a flange body 4, and a gas channel 14 Interference fit with the conical air injection device 12 to prevent the air flow from being exposed. The feed chamber 3 and the swirl chamber 6 are assembled through the first thread 5. The swirl chamber 6 is provided with a guide body 19. The main body of the swirl chamber 6 and the nozzle 7 are connected together by welding.

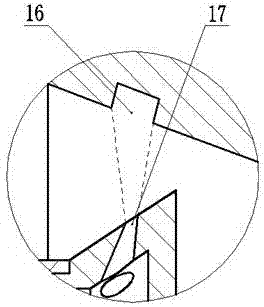

[0029] figure 2 Shown is the main atomization area, when the liquid arrives there from the swirl chamber 6, a low pressure area will be created in the central area, so that it is easier to introduce the gas, and at the same time, there are The evenly distributed eight tapered holes 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com