Magnetorheological fluid flexible support method for thin-wall slab

A magnetorheological fluid and support method technology, which is applied in the direction of support, clamping, positioning devices, etc., can solve the problems that have not been mentioned about the flexible support method of thin-walled plate magnetorheological fluid, and achieve good clamping flexibility and restrain processing Good deformation and magnetic field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

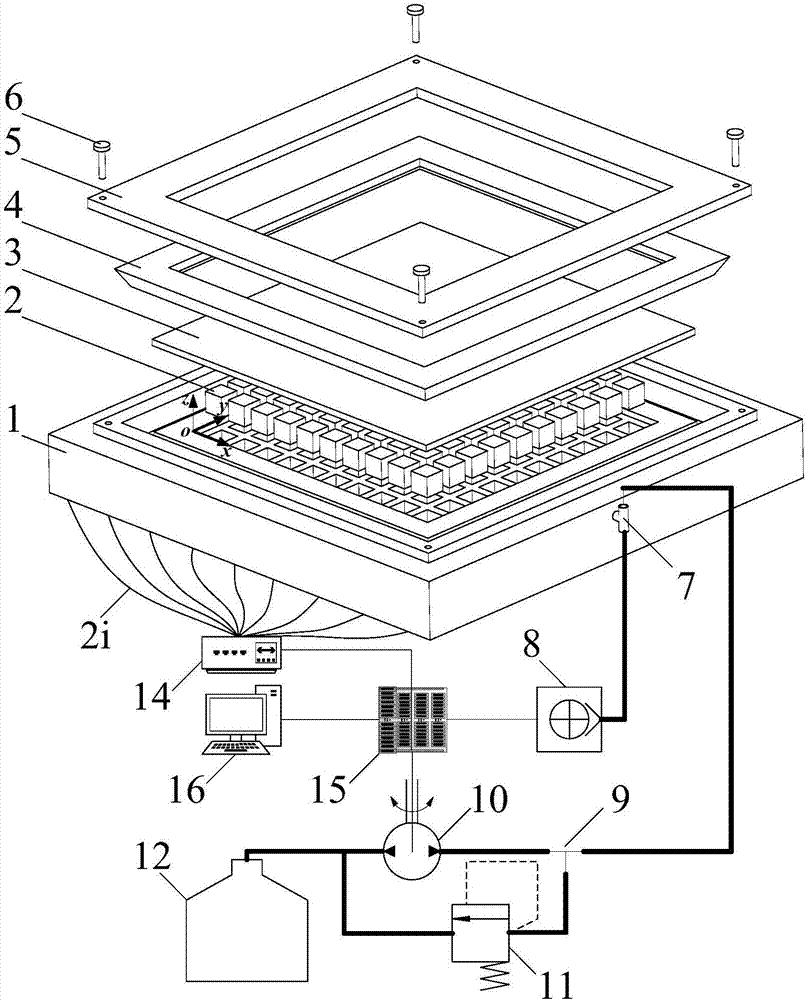

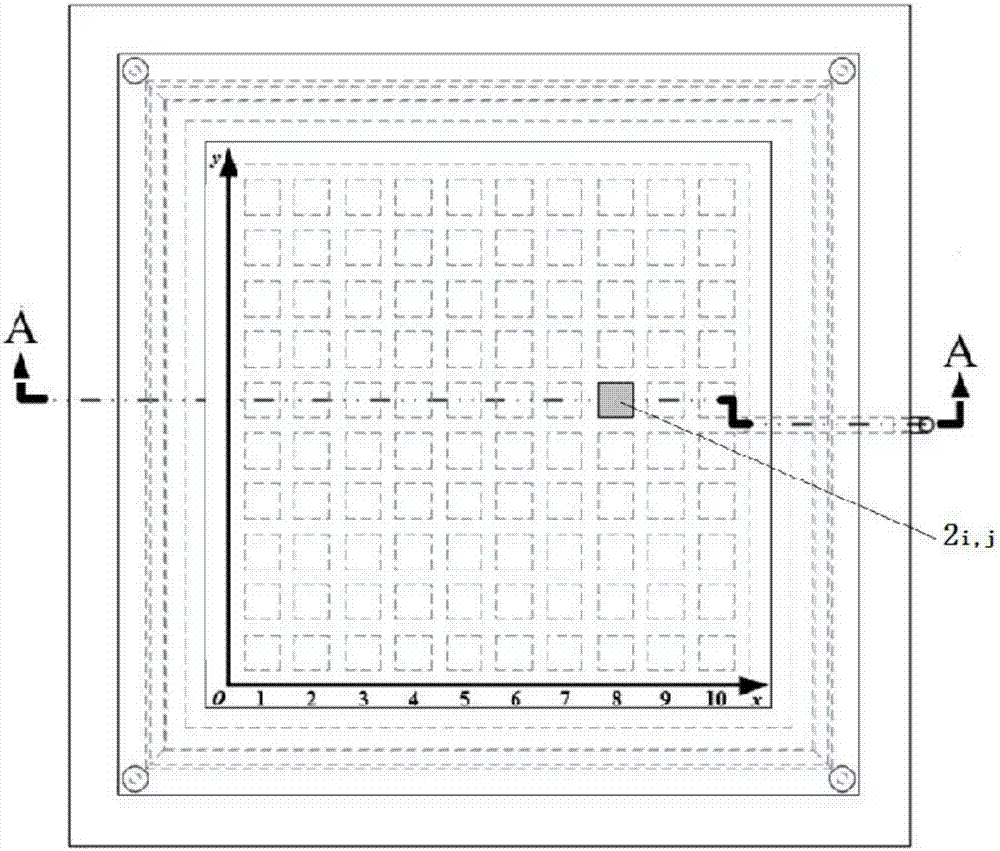

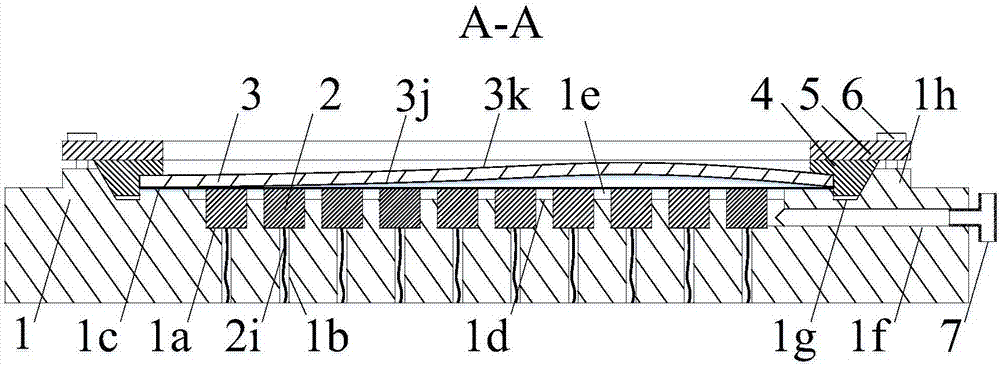

[0028] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions.

[0029] The thin-walled flat plate 3 used in this embodiment is made of aluminum alloy, the surface shape error after roll forming is 0.1-0.2mm, the thickness is 1mm, and the size is 1000mm×1000mm; the excitation unit array is 10×10; figure 1 , 2 shown. Carbonyl iron powder magnetorheological fluid is made of 40% volume fraction of carbonyl iron powder and 60% volume fraction of silicone oil, with a density of 3.55g / ml. The milling force is 100N, the diameter of the milling cutter is 8mm, the maximum thickness of the magnetorheological fluid is 4mm, the viscosity of the magnetorheological fluid is 0.69Pa·s, the extrusion speed is 1mm / s, and the coefficient C related to the medium of the magnetorheological fluid is 0.95. The particle volume fraction is 0.40, and the relative magnetic permeability of magnetorheological fluid is 17.

[0030]In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com