Platen for flat linear motor

A technology of linear motor and platen, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, electrical components, etc. Big losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

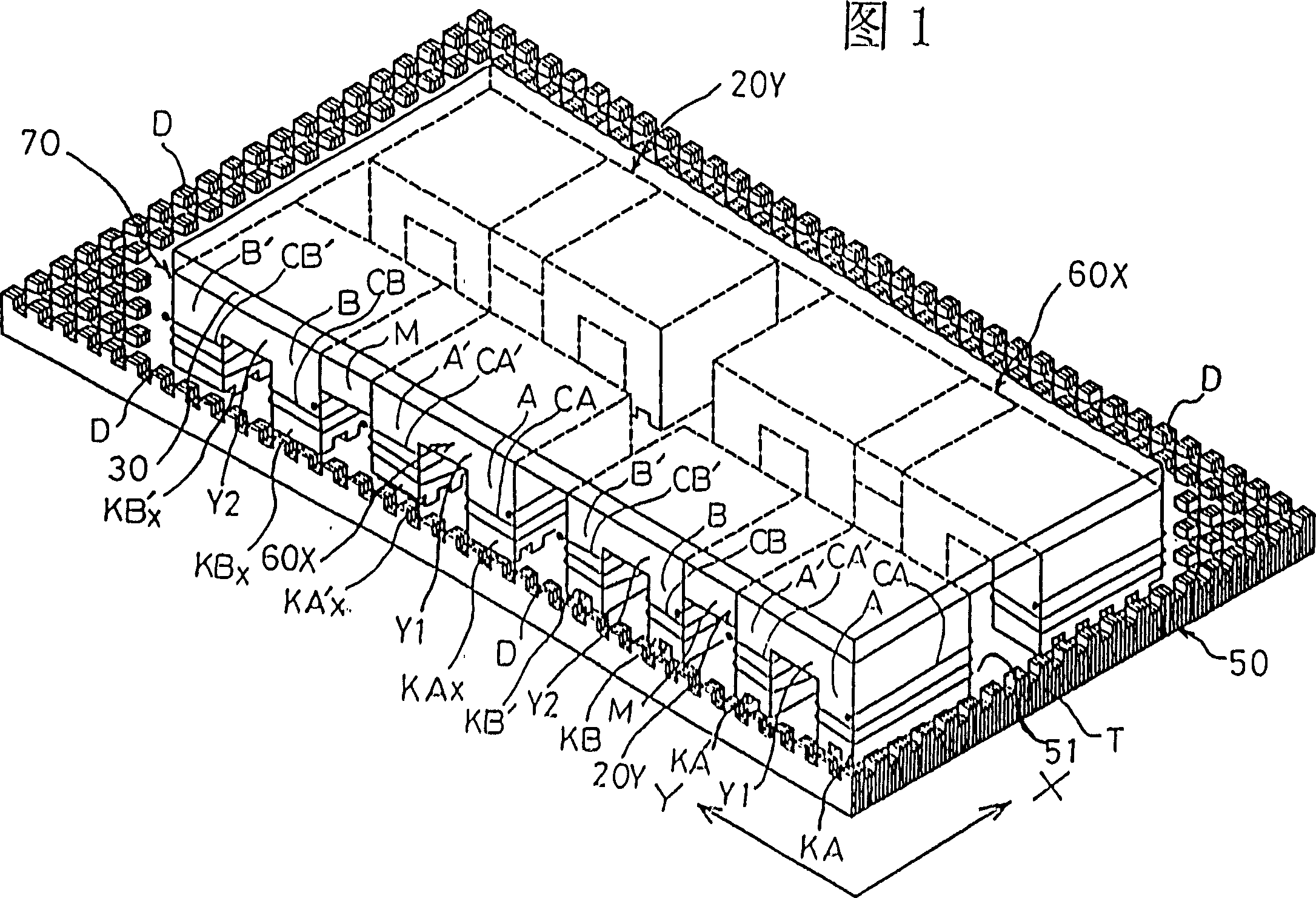

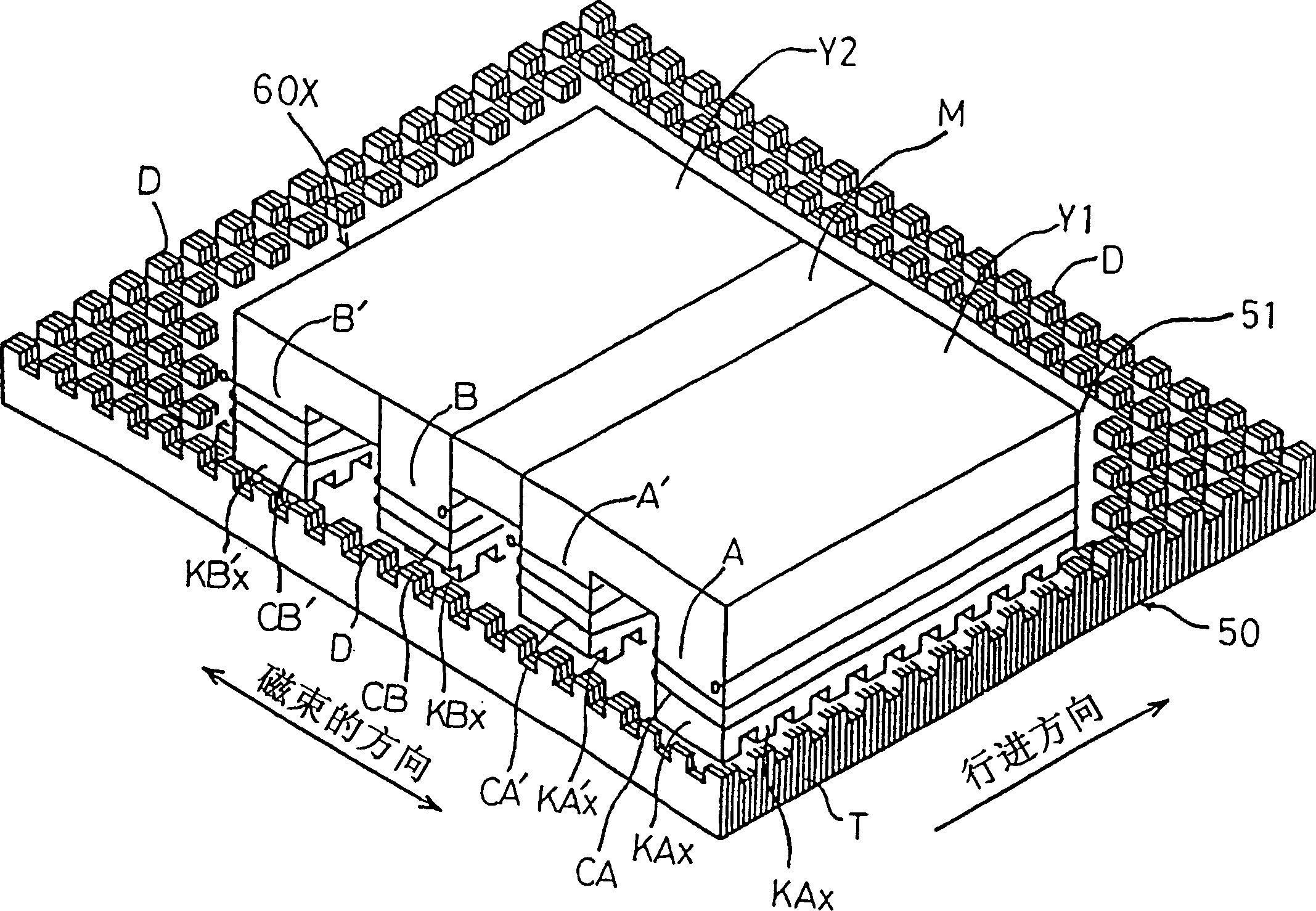

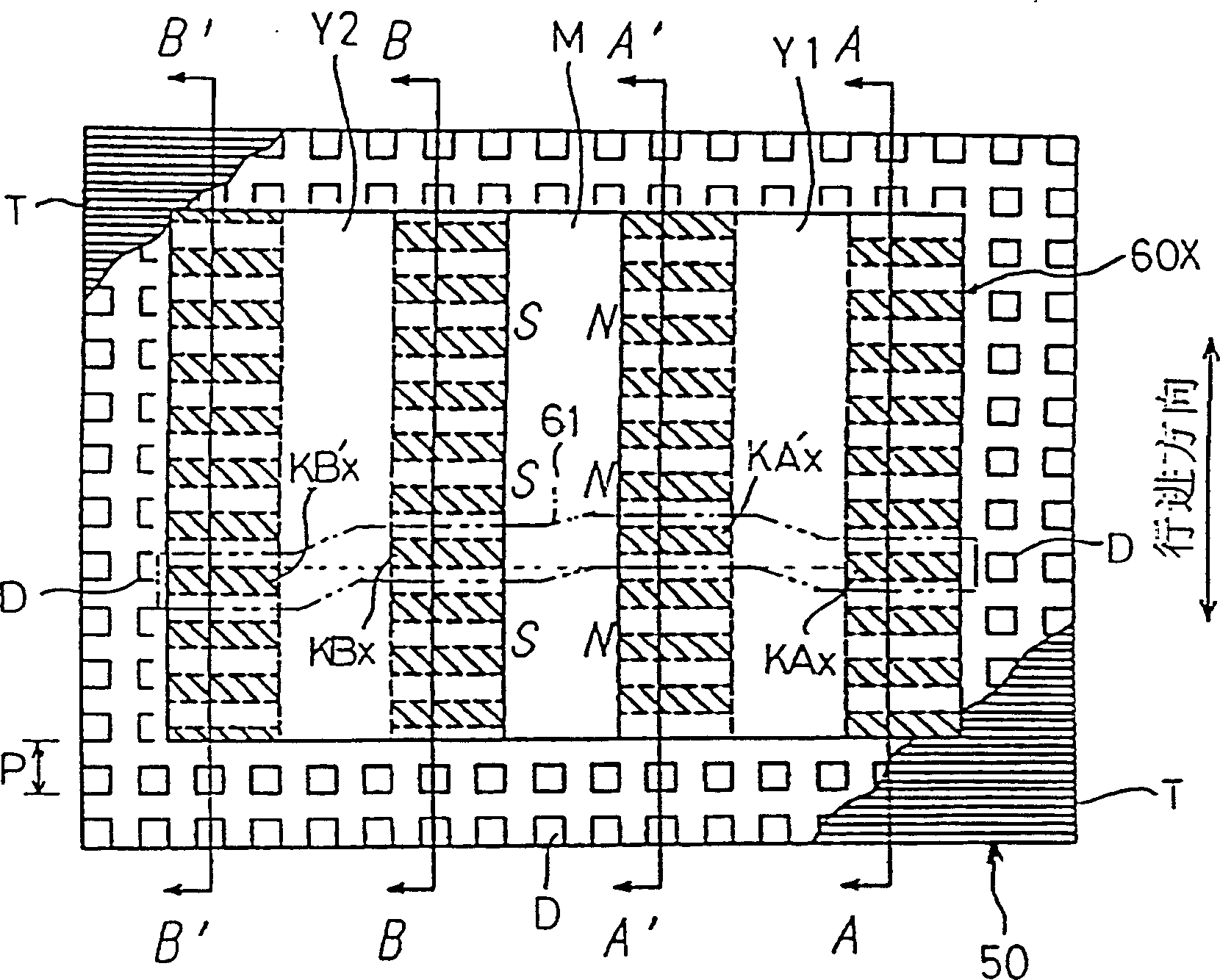

Method used

Image

Examples

Embodiment 1

[0081] Figure 7 is a perspective view showing the platen described in Example 1, Figure 8 is its front view, Figure 9 is its side view. The platen main body 90 has a backing plate 92 overlapping the inner side of the laminated body 91, that is, the parallel surface of the ribs, and the back side of the backing plate 92 is supported by a plurality of connecting beams 93 having a U-shaped cross section. The connecting beams 93 are provided at each discrete position in the direction of the slab, such as Figure 8 As shown, the connecting beams 93 vibrating right and left with the center of the laminated body 91 as a boundary face each other in opposite directions. The connecting beam 93 has an end portion 94 on the upper folded side, and the end portion 94 on the upper folded side is as Figure 9 As shown, extending in a direction perpendicular to the direction of the rib, along the upper bending side end portion 94, it is injected into the upper bending side end portion 9...

Embodiment 2

[0085] 12 is a perspective view showing the platen according to the second embodiment, Figure 13 is its front view, Figure 14 is its side view. In this example, the same reference numerals are used for the same parts as those in Embodiment 1, and the descriptions thereof are omitted.

[0086] The platen main body 90 of this example does not have the backing plate 92 as in the first embodiment, and directly connects the beams 93 to support the laminated body 91 . This example also has the same stitching member and seam 100A of fluid hardening material as in Example 1, but as Figure 15 As shown, there is no through-hole 92a of the backing plate 92 as in the first embodiment, and an embedded joint portion 102A having a short length of the pin shaft is formed. The joint 100A of the fluid hardening material has a stitching function and a connecting function, but since the backing plate 92 is not provided in this example, the outer frame 81 can be used (refer to Image 6 ) co...

Embodiment 3

[0089] Figure 17 It is a perspective view showing the stapling structure described in Example 3. FIG. In this stitching structure, the opening of the through hole 94b on the upper bending side end portion 94 of the connecting beam is formed into a tapered shape, and the joint 100B of the fluid hardening material is embedded in the upper bending side end portion 94 of the joint portion 102B. A dish-shaped thumbtack head with a flat underneath. The dish-shaped thumbtack head of the embedded joint portion 102B has excellent fracture resistance, and can improve the clamping joint strength with the connecting beam 93 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com