Error calibration method based on genetic algorithm for six-degree-of-freedom series robot

A genetic algorithm and error calibration technology, which is applied to manipulators, genetic models, program-controlled manipulators, etc., can solve the problems of increased measurement difficulty and time for the accuracy of data sets, large error parameters, etc., to achieve simplicity and strong applicability , good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

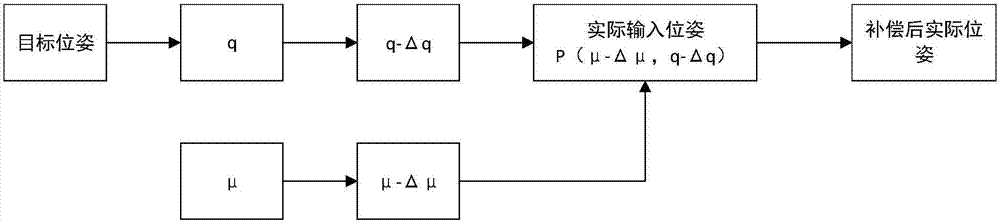

[0050] Specific implementation mode one: combine Figure 1 to Figure 3 and Figure 6 , Figure 7 The error calibration method for a six-degree-of-freedom serial robot based on a genetic algorithm in this embodiment is specifically prepared according to the following steps:

[0051] Step 1, establish the D-H error model of the robot, and introduce the parallel error angle β to establish the actual model of the robot;

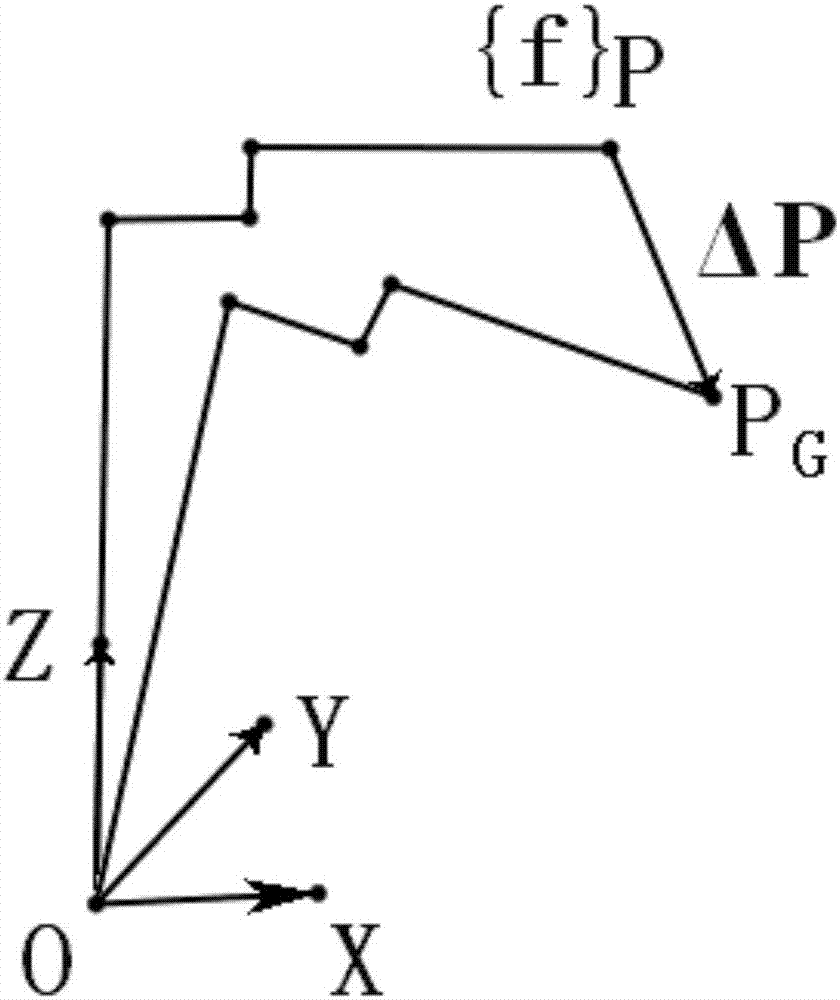

[0052] Step 2. Calculate the actual position P of the tool center of the robot according to the actual model of the robot G , according to P G and the theoretical position point P at the end of the robot arm (P G Theoretical position P) Calculate the robot error model of the robot, that is, the deviation △P:

[0053] ΔP=M θ △θ+M α △α+M a △a+M d △d+M β Δβ;

[0054] Among them, M θ is the joint angle coefficient matrix; M α is the torsion coefficient matrix; M a is the joint offset coefficient matrix; M d is the connecting rod offset coefficient matr...

specific Embodiment approach 2

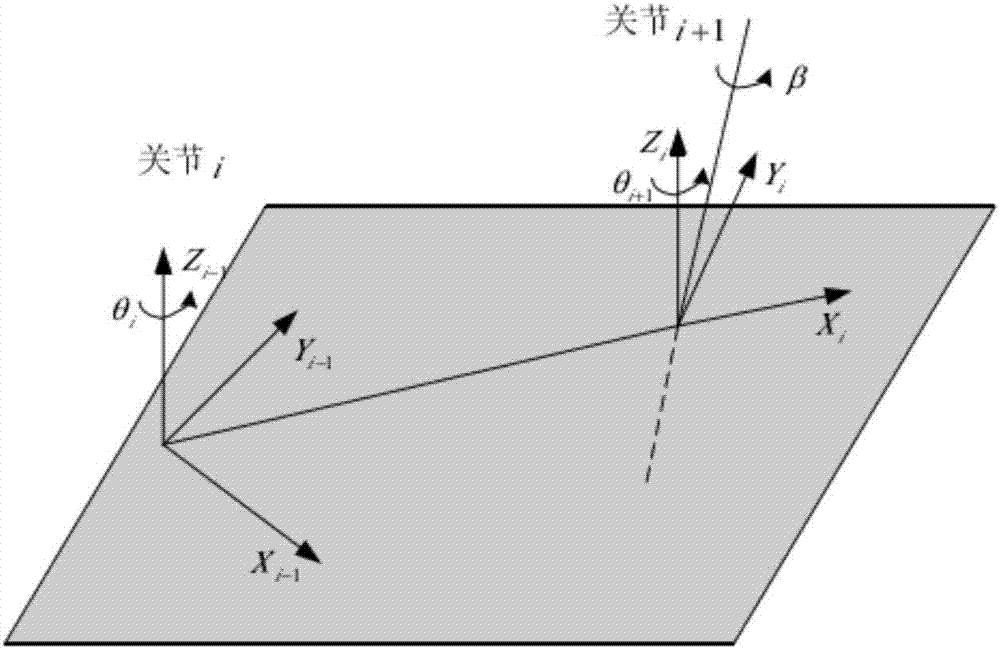

[0086] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the D-H error model of the robot is established in step one, and the actual model of the robot is established by introducing the parallel error angle β, which is specifically:

[0087] Step 11. Establish the D-H error model of the robot, specifying that the axes of the two connected connecting rods are respectively i and i-1; the common normal of the connecting rod axes i and i-1 is set as the length of the connecting rod a i-1 , the angle formed by the two connecting rods is set as the torsion angle αi-1 ; When the two axes i and i-1 are parallel, α i-1 =0; two common normals a i-1 and a i link offset d i , a i-1 and a i The angle between is set as the joint angle θ i ; among them, α i-1 The direction of is defined as the direction from the axis i-1 around the common perpendicular to i;

[0088] Step 12: In the robot D-H error model, add the parallel error angle β...

specific Embodiment approach 3

[0092] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two, calculate the actual position P of the robot tool center according to the actual model of the robot G , according to P G and the theoretical position point P at the end of the robot arm (P G The theoretical position P) calculates the robot error model of the robot, that is, the deviation △P is specifically:

[0093] Step 21. Calculate the actual position P of the tool center of the robot according to the actual model of the robot G , the P G and the theoretical position point P at the end of the robot arm (P G Theoretical position P) represents the deviation △P of the robot:

[0094] P G =P+△P

[0095] Among them, P G is the actual position of the end of the robot arm relative to the robot base coordinate system {O}, which is directly obtained by the laser calibration instrument, {O} is the base coordinate system where the robot is located, point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com