Bentonite slurrying device and slurrying method thereof

A technology of bentonite and preparation equipment, which is applied in the direction of clay preparation equipment, control equipment, clay mixing equipment, etc., can solve the problems of a large amount of manpower, material resources, poor work efficiency, low efficiency, etc., and achieve the improvement of equipment utilization and save temporary construction Low cost and good slurry quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

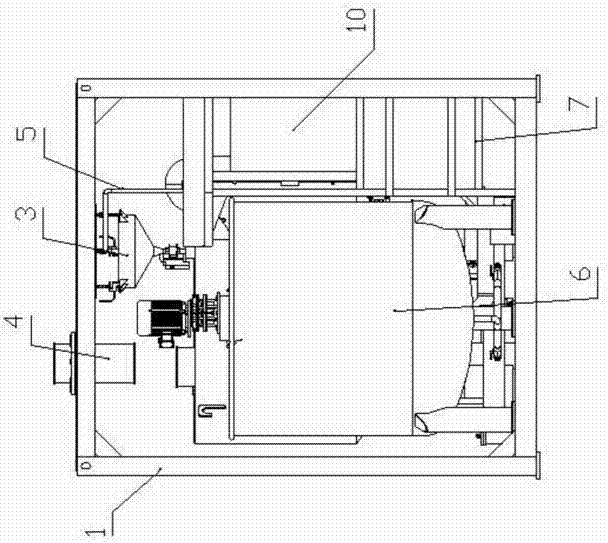

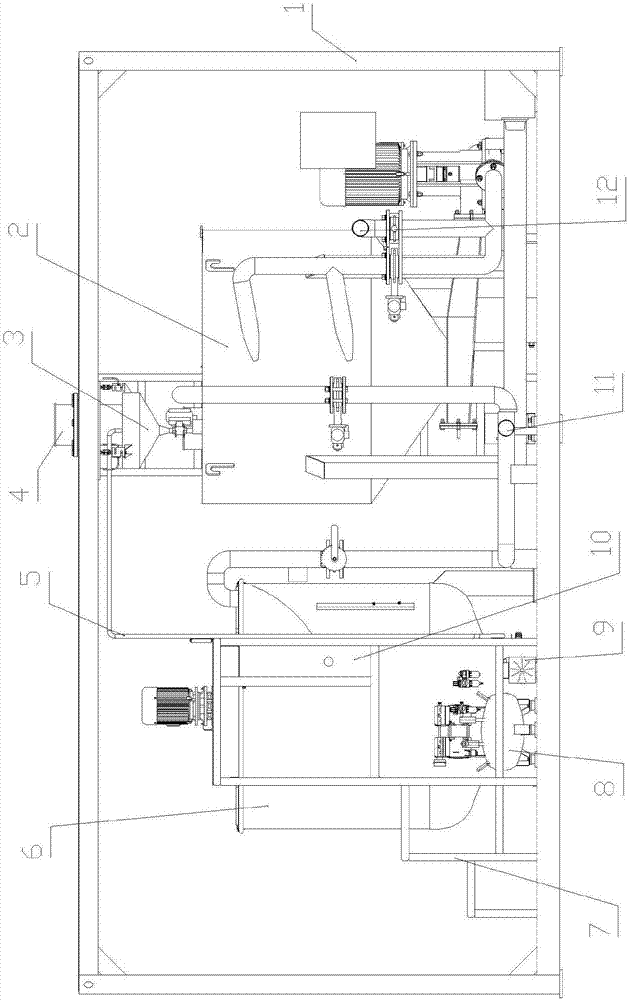

[0033] Such as figure 1 with figure 2 A kind of bentonite pulping device shown comprises: a control terminal, an outer frame 1, and the outer frame 1 has played a role in protecting internal components, and the outer frame 1 is provided with: an alkali preparation device 6, which is used for preparing bentonite slurry The required lye is pretreated. Specifically, water and alkaline materials can be added in the lye preparation device 6, and stirred to obtain the processed lye. The lye preparation device 6 main body described here is hollow The container is not only a place for preparing lye but also can store lye; the slurry mixing device 2 is a key device for preparing bentonite slurry, which can stir water, bentonite, and lye in it to finally obtain bentonite slurry; this implementation Example also includes the lye container 3 that links to each other with the slurry mixing device 2; Also includes the lye delivery pipe 5 that is used to transport the lye in the lye prepar...

Embodiment 2

[0044]Based on the equipment described in Embodiment 1, the specific method of pulping is as follows: water is placed in the lye preparation device 6 and alkaline materials are added, and the stirring device on the lye preparation device 6 is stirred to obtain lye, and the obtained lye The lye is transported to the lye container 3 through the lye delivery pipe 5 under the action of the lye delivery pump 9, and the load cell A arranged on it detects the amount of lye, and when the preset value is reached, the control terminal controls the lye delivery pump 9 Stop transporting lye, the lye in the lye container 3 flows into the slurry mixing device 2, and water and bentonite also enter the slurry mixing device 2 through the water inlet pipe 11 and the feed port 4 respectively, and the load cell B detects the slurry in real time The quality of the solution in the mixing device 2 is stirred by the stirring device on the slurry mixing device 2 to finally obtain bentonite slurry, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com