Mildew-proof and water-proof coil and preparation method

A waterproof membrane and anti-mildew technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of waterproof membranes that have not been reported and are not environmentally friendly, and achieve excellent waterproof and anti-corrosion effects , Good waterproof effect, easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

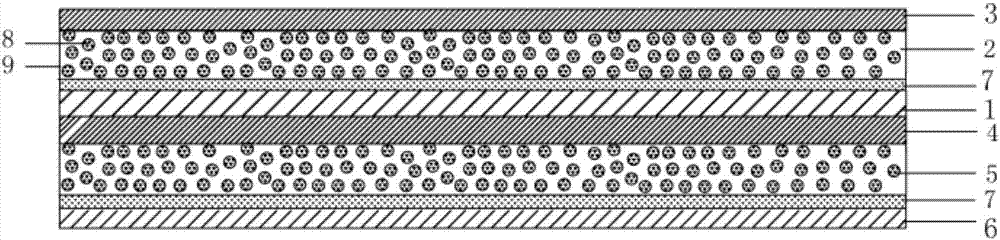

[0028] Such as figure 1 Shown, a kind of mildew-proof waterproof roll material and preparation method of the preferred embodiment of the present invention;

[0029] The mildew-proof and waterproof roll material includes a base material layer 1, which is a glass fiber felt layer, and also includes a first mildew-proof layer 2 arranged on the upper surface of the glass fiber felt layer, the first mildew-proof layer The upper surface of the layer 2 is provided with a first self-adhesive waterproof layer 3, the lower surface of the glass fiber felt is provided with a second self-adhesive waterproof layer 4, and the lower surface of the second self-adhesive waterproof layer 4 is provided with a second anti-mildew layer 5 , the lower surface of the second anti-mold layer 5 is provided with a release layer 6, wherein the glass fiber felt layer 1 and the first anti-mold layer 2 and the second anti-mold layer 5 and the release layer 6 are all bonded Junction layer 7 is connected.

[...

Embodiment 2

[0035] A mildew-proof and waterproof membrane and its preparation method according to the preferred embodiment of the present invention;

[0036]The mildew-proof and waterproof coiled material includes a base material layer, the base material layer is a glass fiber felt layer, and also includes a first mildew-proof layer arranged on the upper surface of the glass fiber felt layer, and the upper surface of the first mildew-proof layer is A first self-adhesive waterproof layer is provided, a second self-adhesive waterproof layer is provided on the lower surface of the glass fiber felt, a second mildew-proof layer is provided on the lower surface of the second self-adhesive waterproof layer, and the second mildew-proof layer A release layer is provided on the lower surface, wherein the glass fiber felt layer is connected to the first anti-mold layer and the second anti-mold layer to the release layer through an adhesive layer.

[0037] Both the first anti-mildew layer and the sec...

Embodiment 3

[0042] The structure of the anti-mildew and waterproof coiled material of the present invention is the same as embodiment 1, and the difference is its preparation method, specifically as follows:

[0043] A layer of graphene-modified EVA foam glue bonding layer is coated on the upper surface of the glass fiber mat, and then the first anti-mildew layer is bonded on the upper surface of the bonding layer. The thickness of the first anti-mildew layer is 1.0 mm, and then A graphene-modified epoxy resin layer is coated on the upper surface of the mildew-proof layer, and the thickness of the modified epoxy resin layer is 0.4 mm; the lower surface of the glass fiber mat is coated with a graphene-modified epoxy resin layer, and the thickness is 0.6 mm, and then Bond the second anti-mildew layer on the lower surface of the epoxy resin layer, the thickness of the second anti-mildew layer is 0.5mm, then coat the glue bonding layer on the lower surface of the second anti-mildew layer, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com