Comb-type polyether sulphone material containing long side group structure and preparation method of comb-type polyether sulphone material

A polyarylethersulfone and membrane material technology is applied in the field of comb-type polyarylethersulfone membrane material containing long side group structure and its preparation, which can solve the problems of molecular chain degradation, difficulty in accurately regulating the molecular structure and performance of polymers, and the like. Achieve the effect of simple preparation process, good gas separation performance, and good dissolution and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

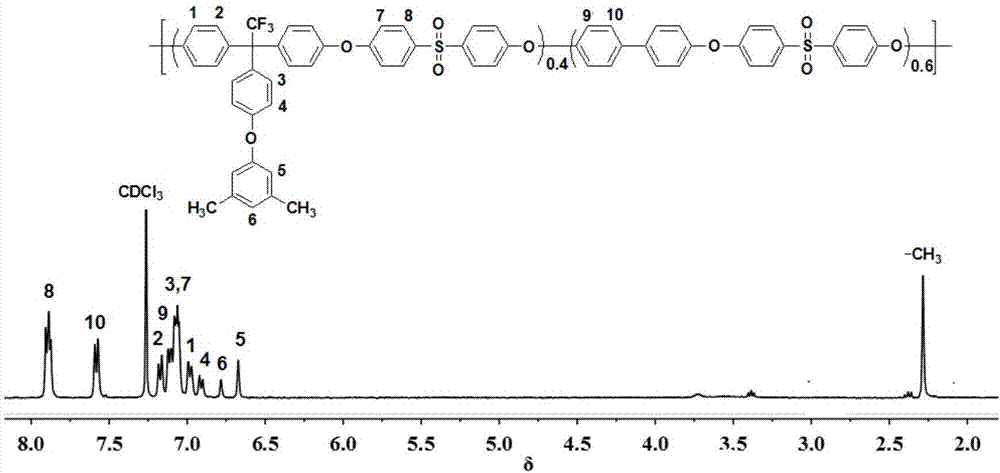

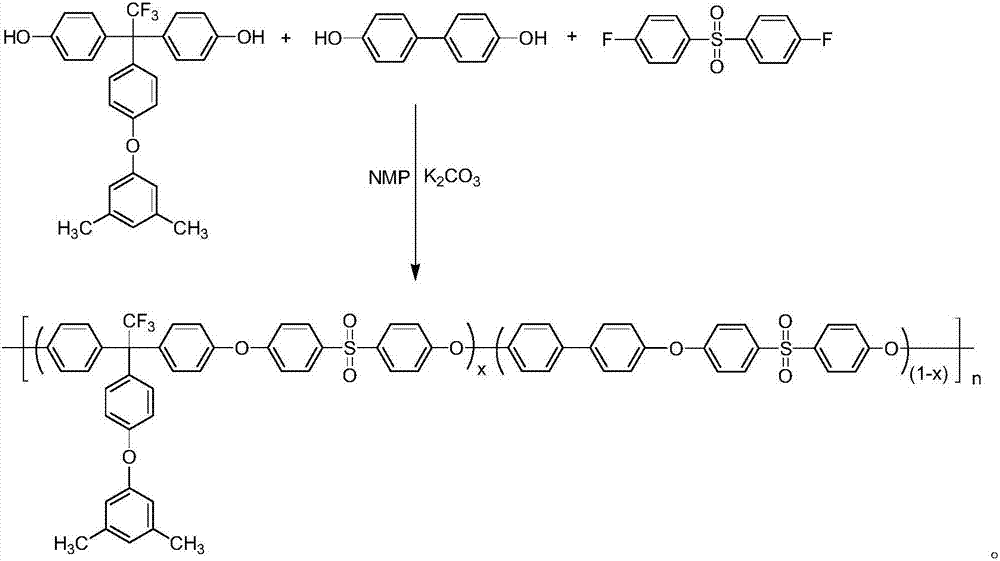

[0020] (1) In a 100ml dry three-necked flask equipped with mechanical stirring, nitrogen protection and water separator, add 1.8579g (4mmol) of 1,1-bis(4-hydroxyphenyl)-1-(4-(3 ,5-Dimethyl)phenoxy)phenyl-2,2,2-trifluoroethane (taking x = 0.4 as an example for the content of large substituted side group structural units in sparse shape), 1.1173g (6mmol) of biphenyl Diphenol, 2.5425g (10mmol) of 4,4'-difluorodiphenylsulfone monomer, 1.3821g (10mmol) of potassium carbonate, 11ml of N-methylpyrrolidone and 5ml of toluene, azeotropic dehydration at 110°C for 4h Afterwards, the temperature was further raised to 150° C. for co-condensation reaction for 10 h, the reaction was terminated, and the reaction solution was poured into ethanol to obtain a fibrous comb-type polyarylethersulfone resin with a long side group structure, with a yield of 99%; 1 H NMR (CDCl 3 ,400MHz) as attached figure 1 shown.

[0021] (2) Further dissolve the comb-type polyarylethersulfone resin containing lo...

Embodiment 2

[0023] (1) In a 100ml dry three-necked flask equipped with mechanical stirring, nitrogen protection and water trap, add 2.7869g (6mmol) of 1,1-bis(4-hydroxyphenyl)-1-(4-(3 ,5-Dimethyl)phenoxy)phenyl-2,2,2-trifluoroethane (taking x = 0.6 as an example for the content of large substituted side group structural units in sparse shape), 0.7448g (4mmol) of biphenyl Diphenol, 2.5425g (10mmol) of 4,4'-difluorodiphenylsulfone monomer, 1.7967g (13mmol) of potassium carbonate, 23ml of N-methylpyrrolidone and 6ml of toluene, azeotropic dehydration at 140°C for 2h Afterwards, the temperature was further raised to 170° C. for 5 hours of co-condensation reaction, and the reaction was terminated. The reaction solution was poured into ethanol to obtain a fibrous comb-type polyarylethersulfone resin with a long side group structure, with a yield of 99%.

[0024] (2) Further dissolve the comb-type polyaryl ether sulfone resin containing long side group structure in N-methylpyrrolidone solution t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap