A garment ironing and setting machine

A technology for ironing and setting machine and setting machine, which is applied in the fields of sales and clothing production, can solve the problems of clothing ironing loss, clothing odor, easy failure of thermal switches, etc., so as to improve ironing quality, prevent clothing from discoloration, and eliminate clothing discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

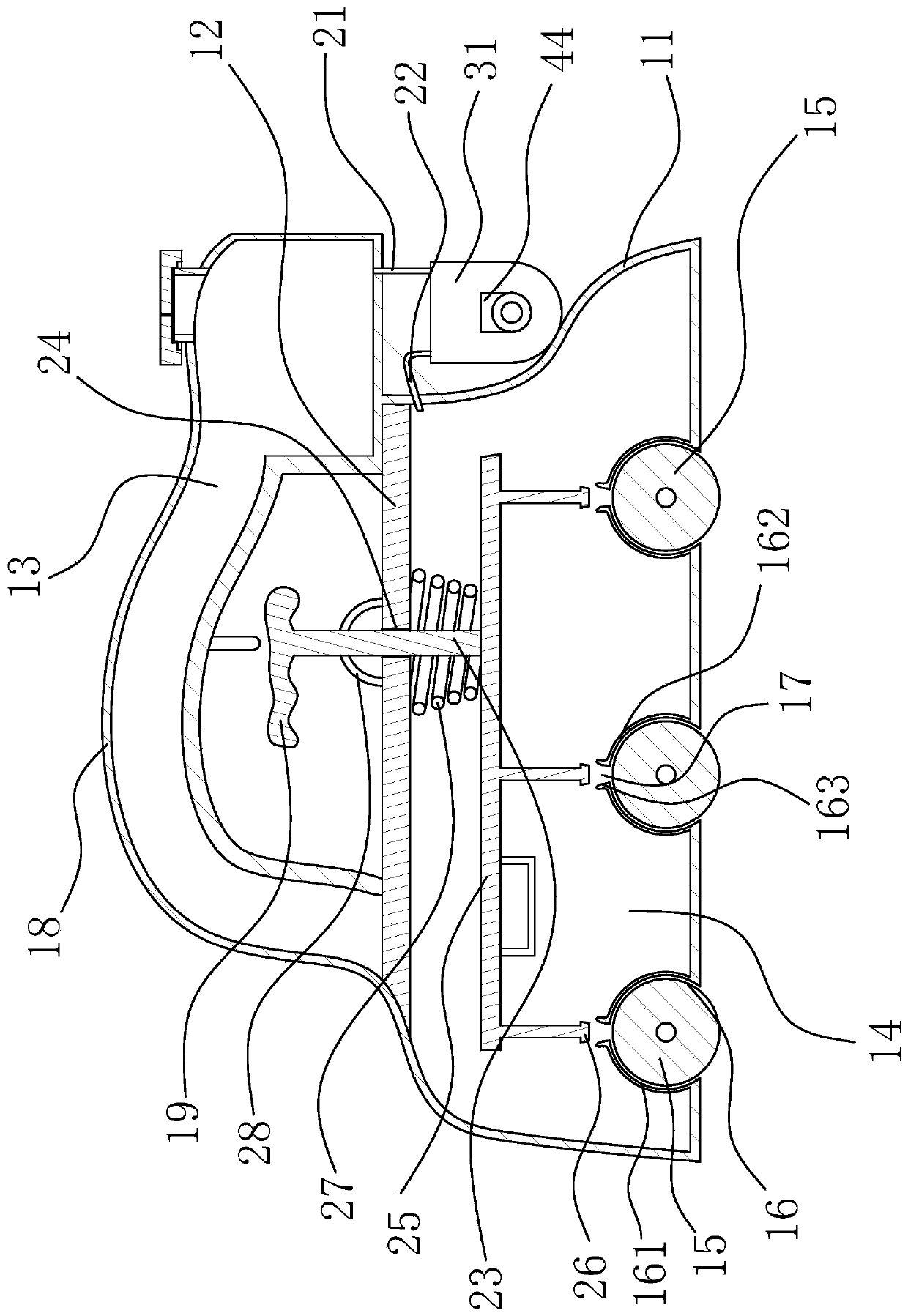

[0049] Such as figure 1 As shown, the ironing and setting machine includes a setting machine body 11. The setting machine body 11 is a hollow structure. A partition 12 is arranged inside the setting machine body 11. The partition 12 divides the inner cavity of the setting machine body 11 into upper liquid storage. Cavity 13 and the atomizing chamber 14 of the lower part, the lower end of the sizing machine body 11 is provided with several rollers 15, and the roller 15 part protrudes from the lower end surface of the sizing machine body 11, and the bottom of the sizing machine body 11 is provided with rollers 15 outer contours. And the avoidance groove 16 sunken in the atomization chamber 14, the top of the avoidance groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com