A kind of polyurethane bridge shock-absorbing support and shock-absorbing method thereof

A technology of shock-absorbing bearings and polyurethane, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of high cost of bridge piers, achieve the effects of small structural size requirements, flexible rotation, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

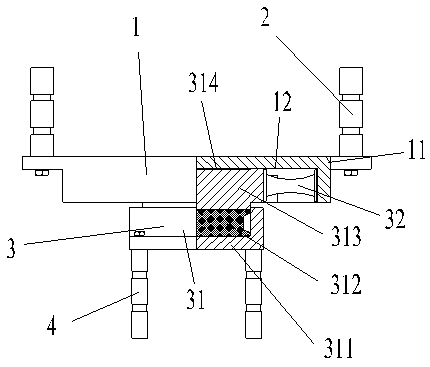

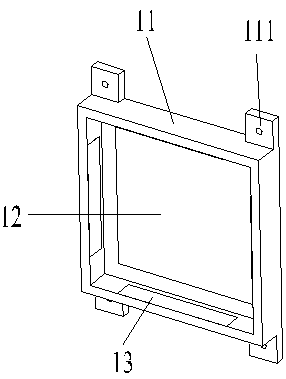

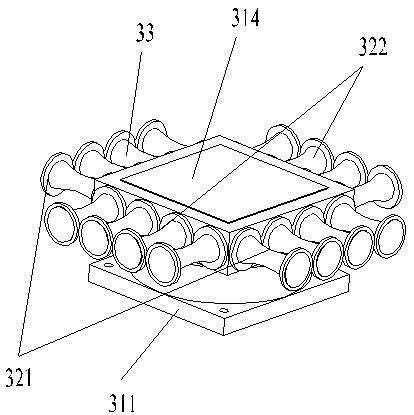

[0036] Such as Figure 1-Figure 4 As shown, a polyurethane bridge shock-absorbing support includes an upper seat plate assembly 1 and a lower seat plate assembly 3, the upper seat plate assembly 1 is arranged directly above the lower seat plate assembly 3, and the lower seat plate assembly 1 includes a support member 31 and a slide The moving part 32 and the supporting part 31 are located in the middle of the entire lower seat plate assembly 3, and are mainly used to bear the vertical load. The fulcrum; the sliding part 32 is arranged around the upper end of the supporting part 31, used to alleviate the vibration generated during horizontal sliding or rotation, and together with the upper seat plate assembly 1 constitutes a horizontal shock absorbing part.

[0037] Further, the sliding part 32 includes a horizontal sliding body 321 and a longitudinal sliding body 322,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com