Automatic transmission and vehicle

An automatic transmission and brake technology, which is applied to vehicle parts, vehicle gearboxes, transmission elements, etc., can solve the problems of increasing the difficulty of processing and manufacturing the automatic transmission case, increasing the volume and weight of the automatic transmission, and increasing the strength of the case. Achieve the effect of improving the load condition, reducing the loss of oil churning, and reducing processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0043]The object of the present invention is to provide an automatic transmission and a vehicle with the automatic transmission. The automatic transmission can be equipped with six forward gears and one reverse gear by changing the connection modes of planetary gear sets, brakes and clutches. Under the premise of reducing the number of brakes and increasing the number of clutches, the structure of the automatic transmission is more compact and the transmission efficiency is higher.

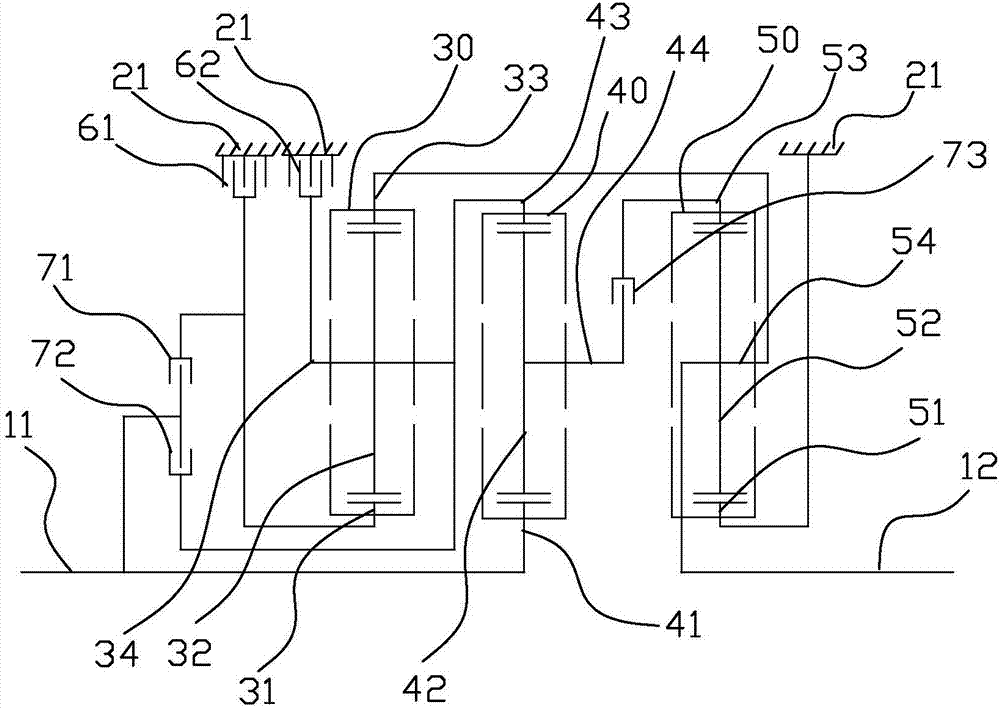

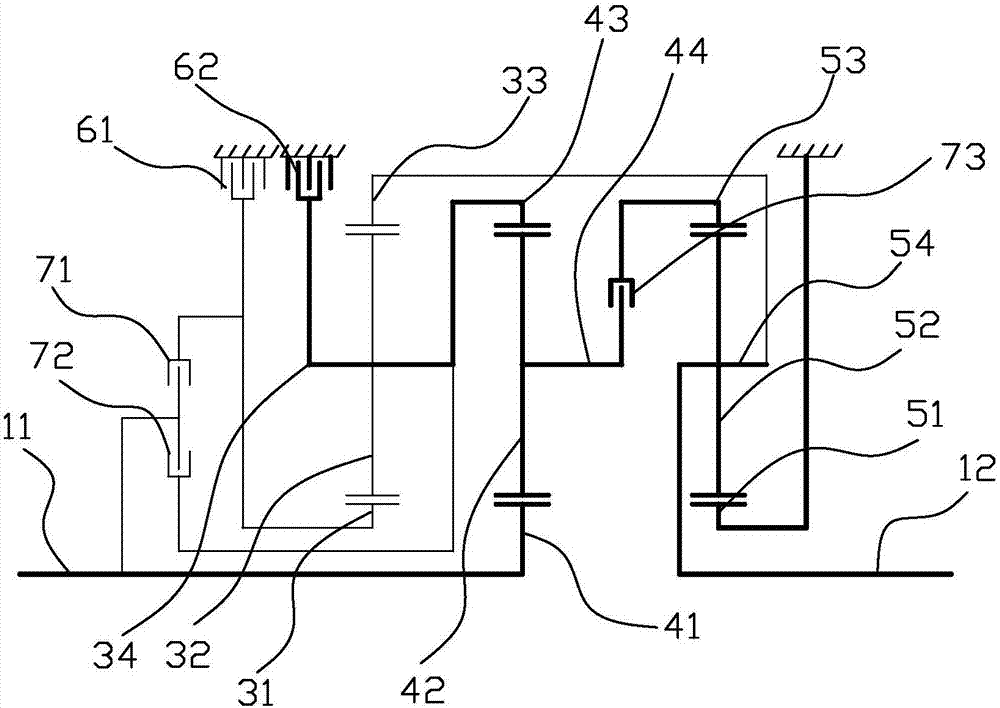

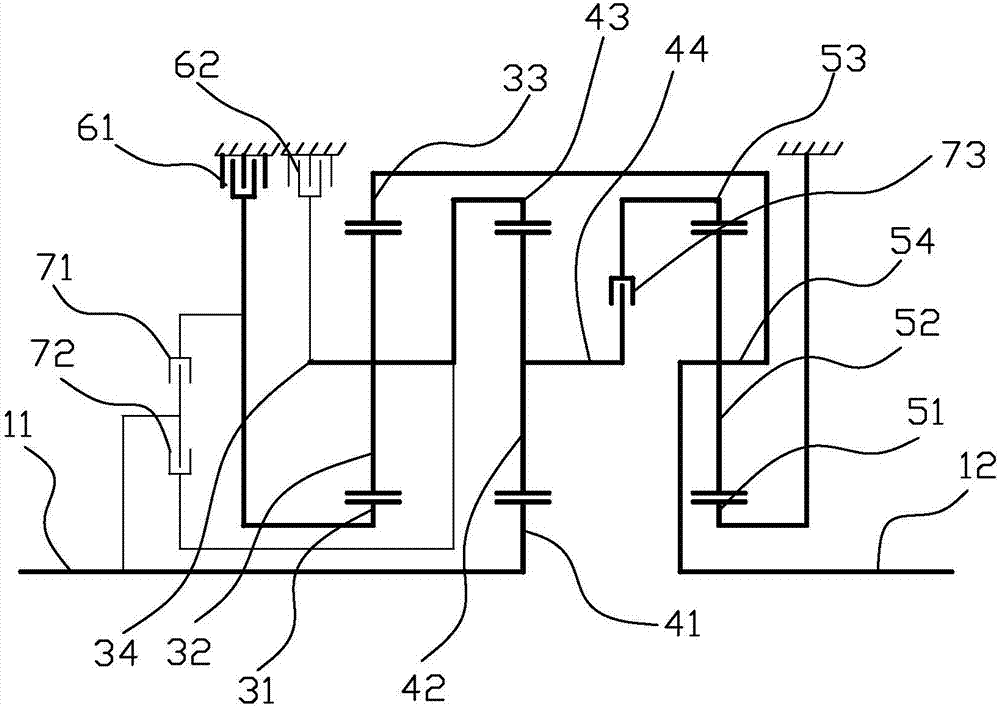

[0044] figure 1 It is a schematic structural diagram of the automatic transmission provided by the first embodiment of the present invention. Such as figure 1 As shown, the automatic transmission provided by the first emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com