A film-sealed piezoelectric-driven micro-spray lubrication device

A piezoelectric-driven, spray-lubricated technology, applied in the direction of engine lubrication, engine components, bearing components, etc., can solve problems such as mechanical failure of spacecraft precision parts bearings, improve energy utilization, increase the scope of application, and increase pressure The effect of wave strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

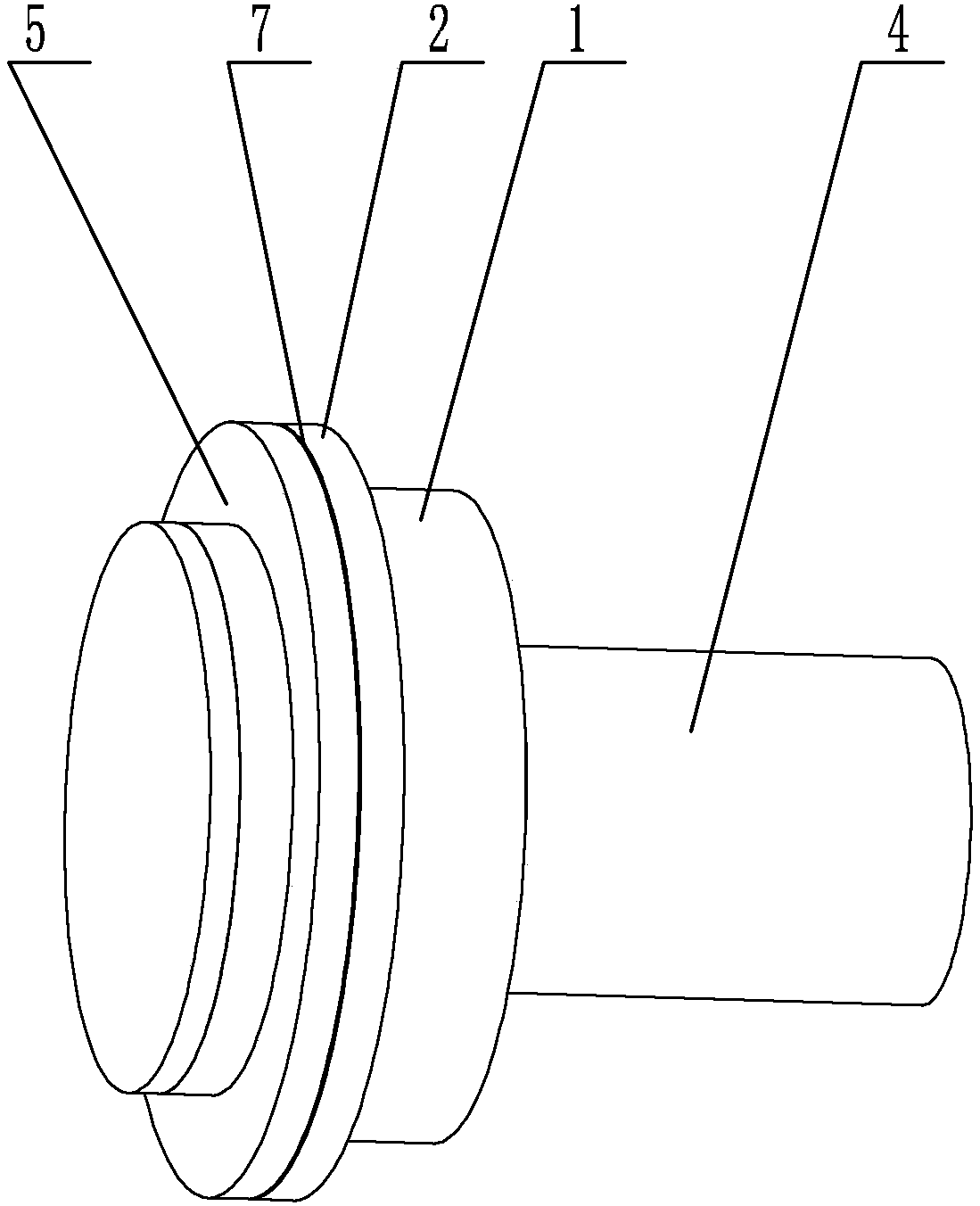

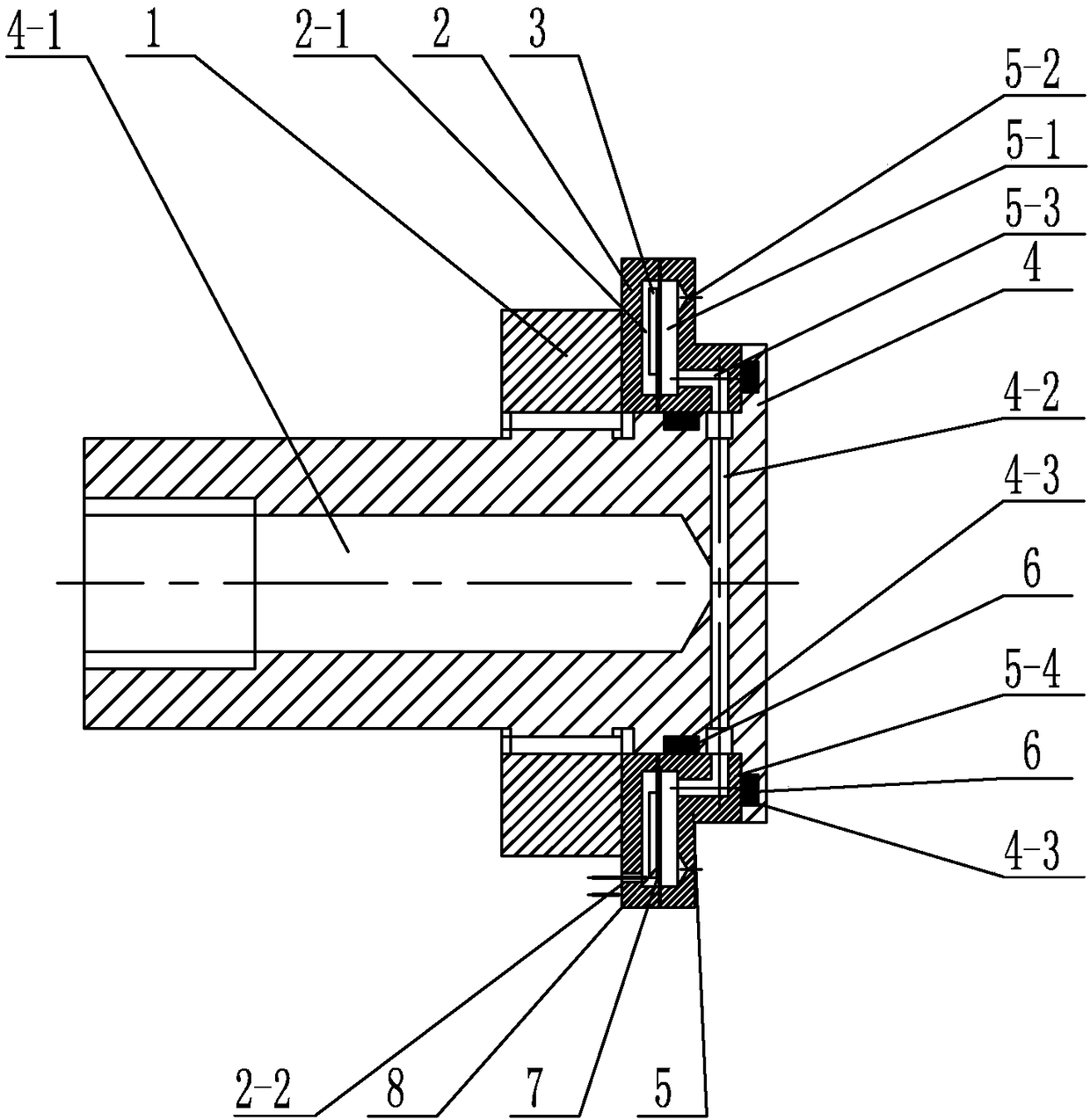

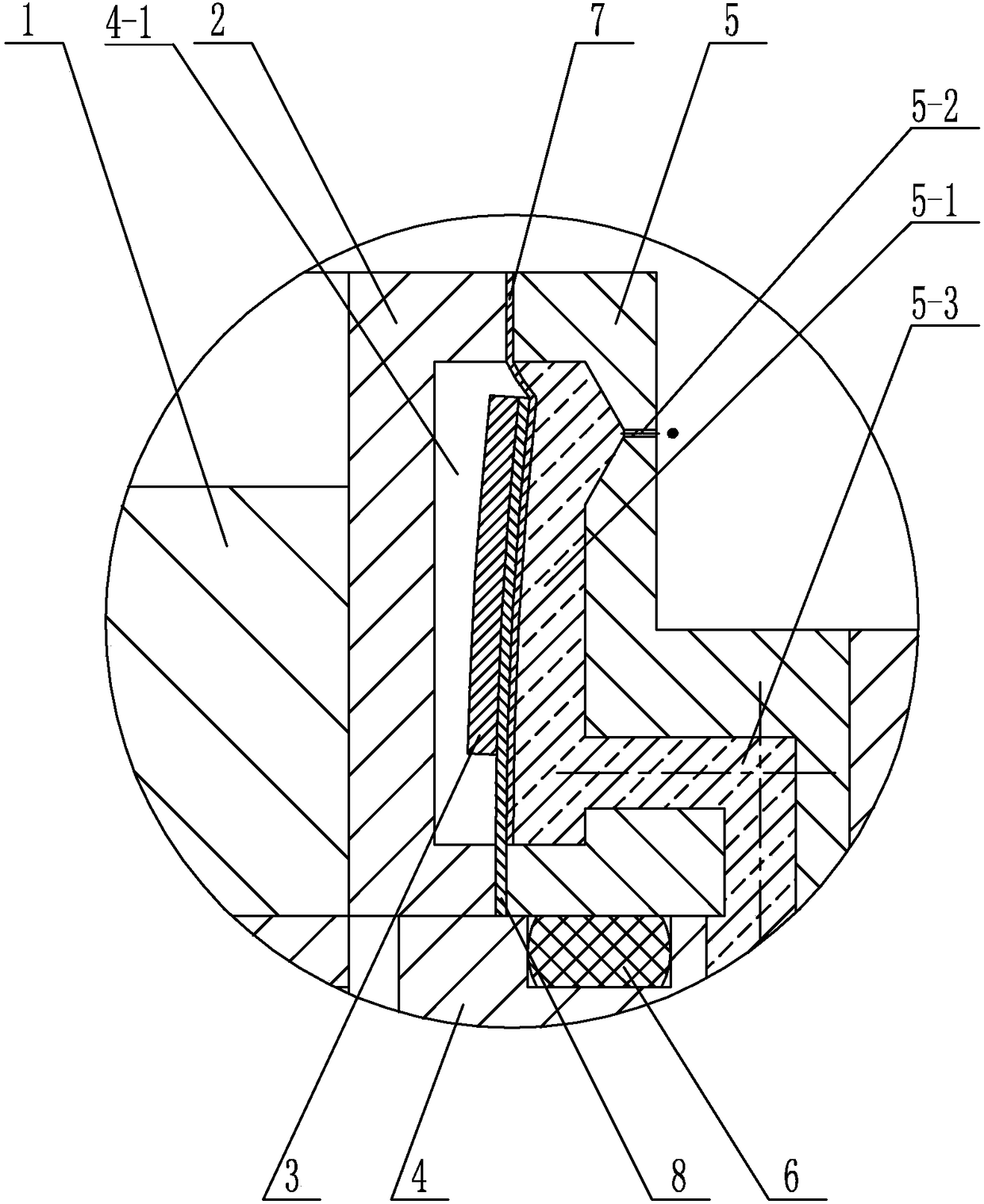

[0024] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, a film-sealed piezoelectric-driven micro-spray lubrication device described in this embodiment includes a lock nut 1, a micro-spray rear cover 2, an oil supply mandrel 4, a micro-spray front cover 5, and a piezoelectric vibrator , the middle part of the rear end of the oil supply mandrel 4 is provided with an oil supply chamber 4-1 along the axial direction, and the front end of the oil supply chamber 4-1 is symmetrically provided with a plurality of oil supply passages 4-2 along the radial direction, and the oil supply passage 4 -2 communicates with the oil supply chamber 4-1, the micro-spray rear cover 2 and the micro-spray front cover 5 are set on the outside of the oil supply mandrel 4, the micro-spray front cover 5 is fixedly connected to the oil supply mandrel 4, and after micro-spray Cover 2 is arranged on the rear end of micro-spray front cover 5, and the rear end of micro...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 1 to Figure 5 Describe this embodiment, the elastic film 7 described in this embodiment is fixed on the front end surface of the copper sheet 8, the piezoelectric ceramic sheet 3 is fixed on the middle part of the rear end surface of the copper sheet 8, and the inner side of the copper sheet 8 is fixed on the front end surface of the copper sheet 8. The inner side between the cover 2 and the micro-spray front cover 5, the outer side of the copper sheet 8 is arranged in the annular groove 2-1, and the outer side of the elastic film 7 is fixed on the outer side between the micro-spray rear cover 2 and the micro-spray front cover 5 , The inner side of the elastic film 7 is set in the injection chamber 5-1. Other compositions and connection methods are the same as those in Embodiment 1.

[0031] In this embodiment, the elastic film 7 is fixed on the front end surface of the copper sheet 8 , the inner diameter of the cop...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 2 Describe this embodiment, the rear end surface of the micro-sprayed back cover 2 described in this embodiment is provided with through hole 2-2, and the positive electrode lead wire of driving power is connected with piezoelectric ceramic chip 3, and draws out from through hole 2-2, drives The negative electrode lead wire of the power supply is connected with the back cover 2 of micro-spraying. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com