Apparatus for endothermic process with improved burners arrangement

一种燃烧器、端部燃烧的技术,应用在燃烧方法、燃烧设备、燃烧器等方向,能够解决加热缺乏均匀性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

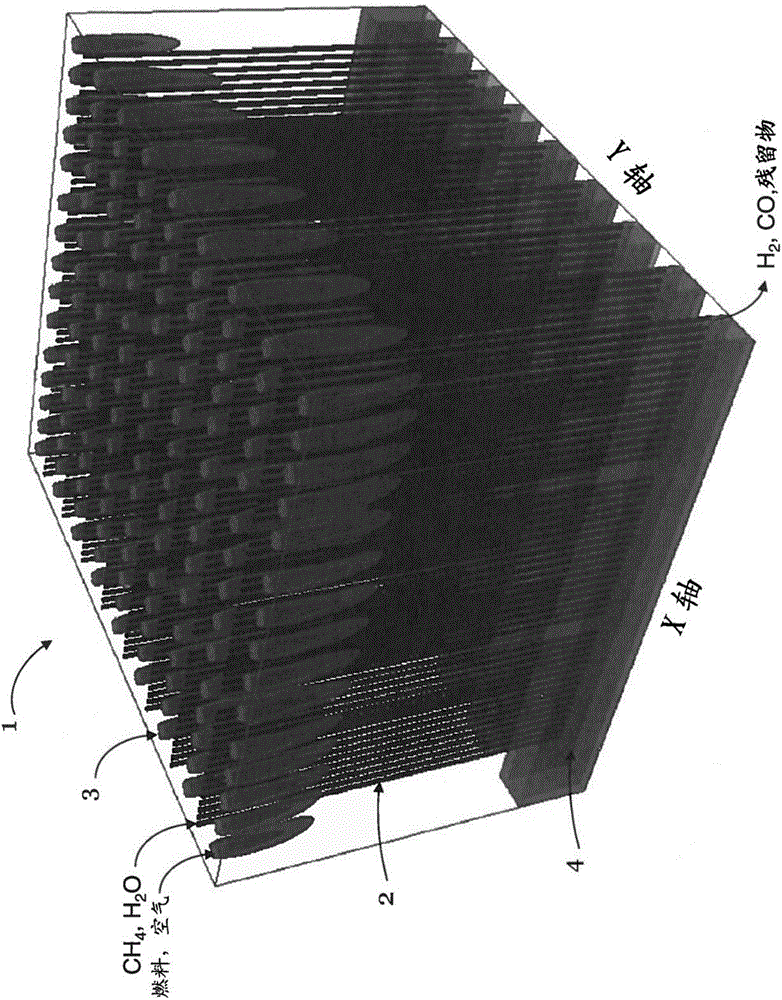

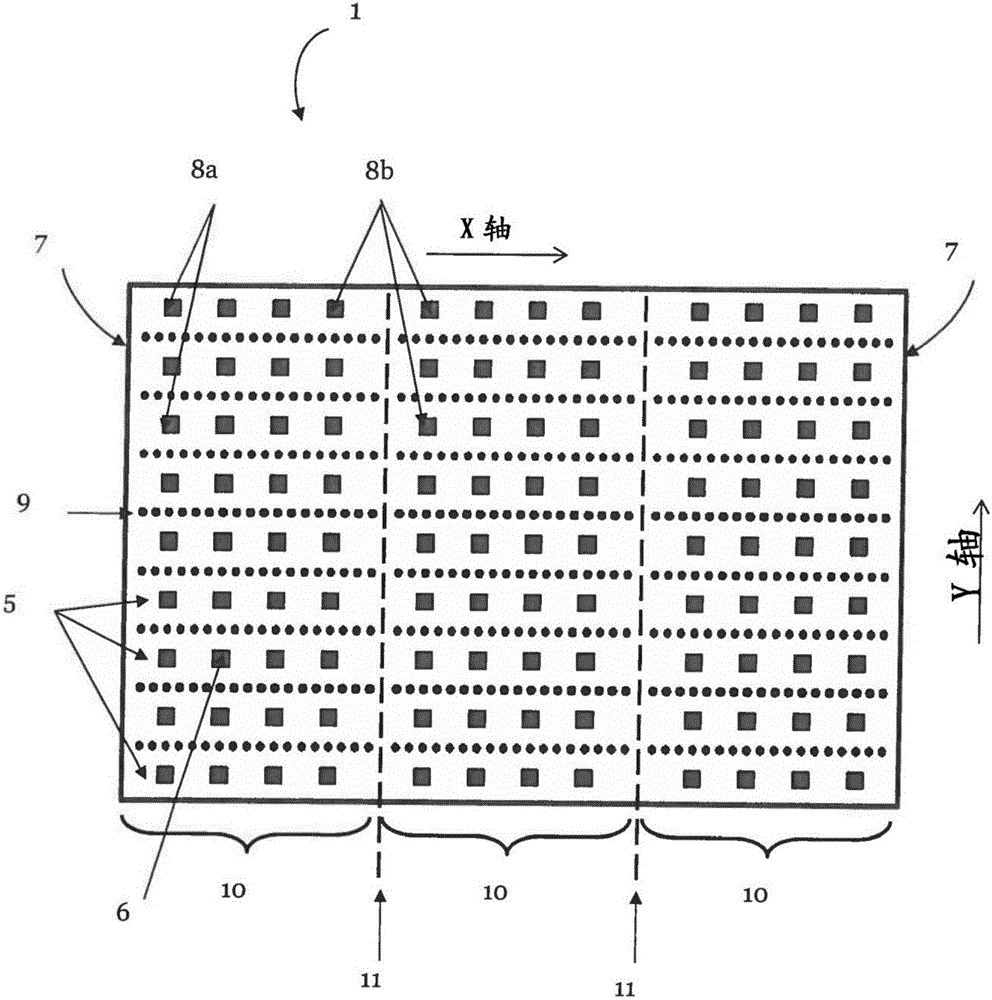

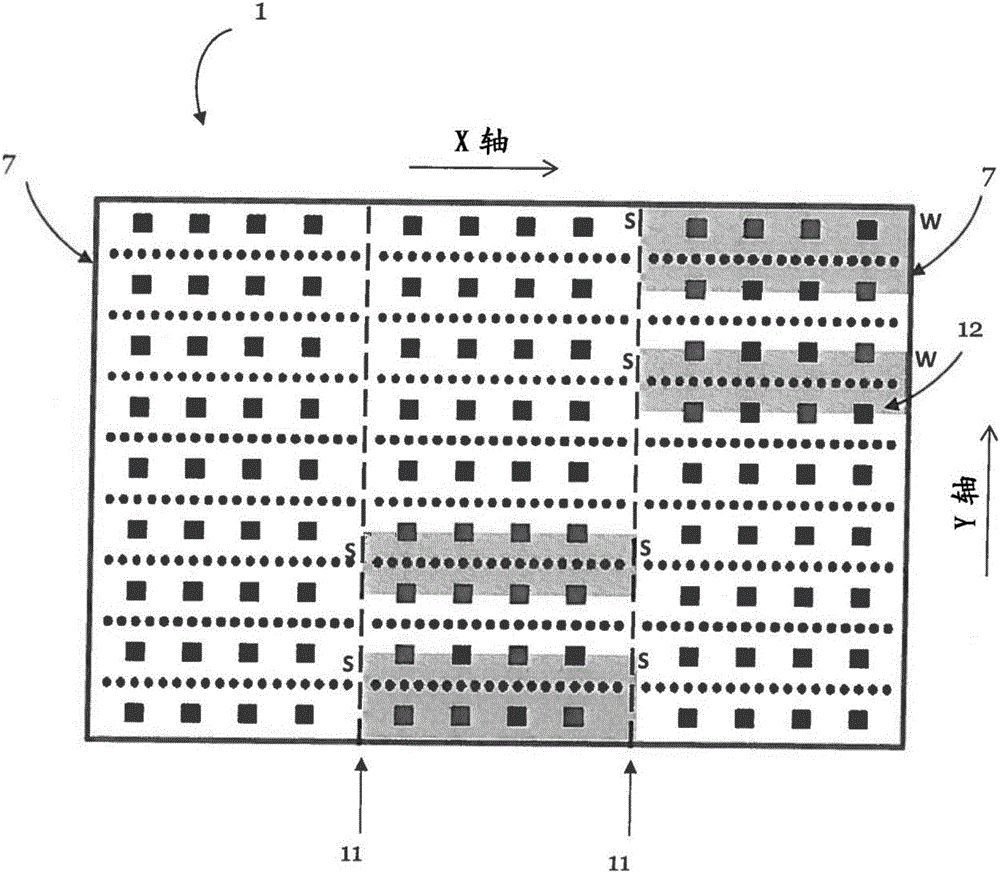

[0068] As stated above, the present invention aims at proposing a top-fired or bottom-fired furnace for performing endothermic methods / processes / procedures - these furnaces operate in figure 1 The improved design of - shown in ; the purpose is to alleviate the temperature variation along the row of burners parallel to the tube row - along the X axis - due to the improved arrangement of the burners along the row of Subdivided to have the same power.

[0069] In order to be able to recognize and propose an optimal arrangement of burners along a row, many simulations have been performed for different arrangements of burners of the same power along a row of burners for multiple SMR plants.

[0070] The tool used to identify the optimal subdivision of the burner in the "typical span" is the tool used above to address the lack of uniformity in flame jet and tube temperature caused by existing designs.

[0071] A numerical simulation of a typical span of a top-fired SMR was performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com