Super surface-based small-scale microwave frequency-reconfigurable coupler

A microwave frequency and coupler technology, used in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of small tuning range, high cost, and high loss, reducing loss, increasing frequency tuning range, and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

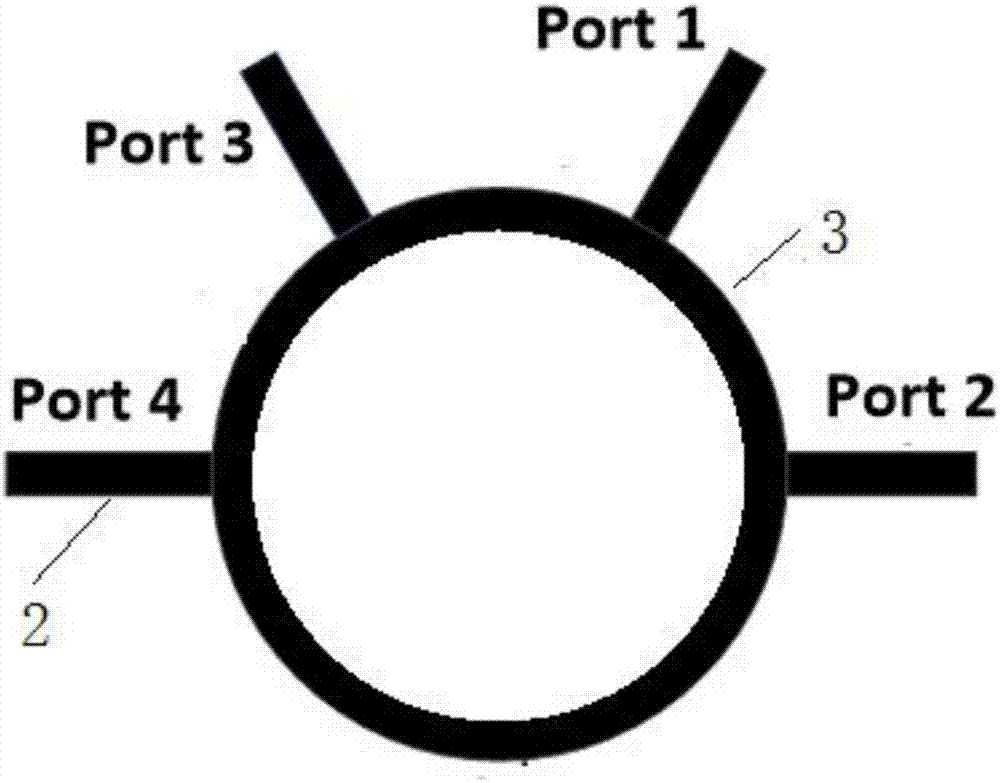

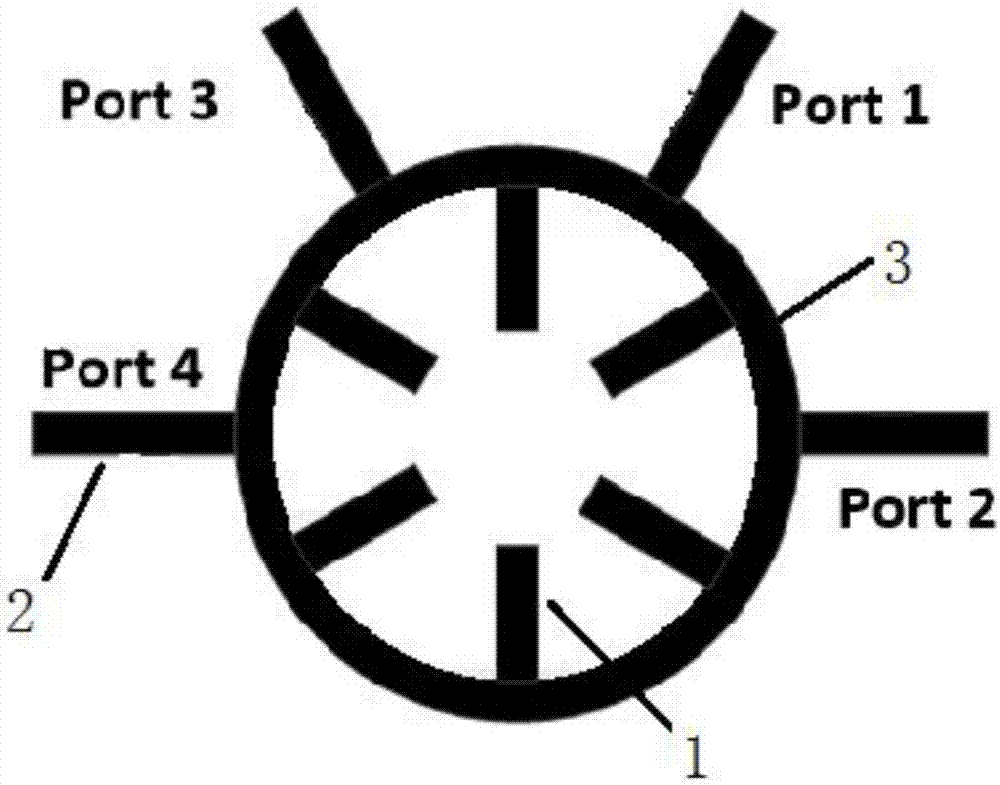

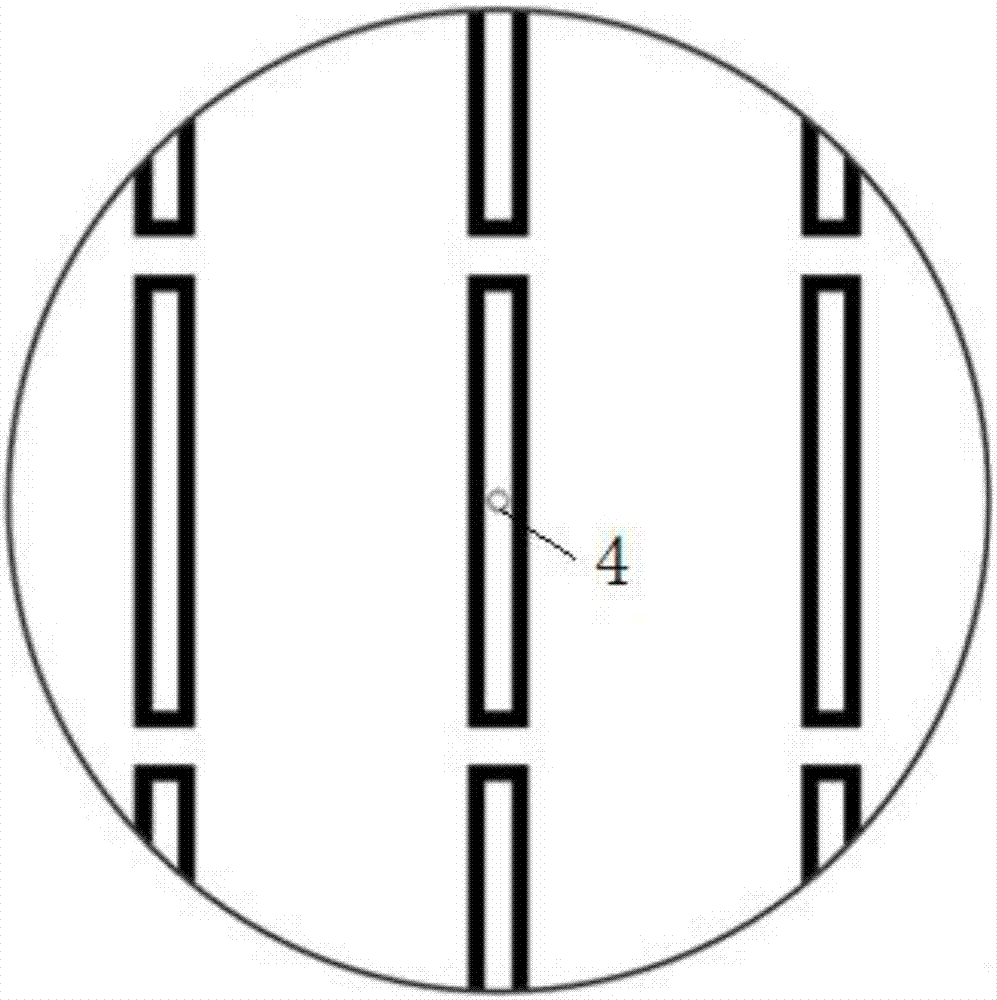

[0039] This implementation provides a small microwave frequency reconfigurable coupler based on metasurfaces, including an upper circular structure with equal radius and thickness, a lower circular structure, and the upper circular structure and the lower circular structure pass through the center of the circle set at the center of the circle The hole 4 and the metal rod set through the center hole 4 realize structural fixation and relative angle tuning; the upper surface of the upper circular structure is a metasurface; the upper surface of the lower circular structure is fixed with a ring coupler, and the lower surface is a contact ground. Such as image 3 , the metasurface consists of periodically distributed rectangular metallic ring structures. The specific structure of the rectangular metal ring structure is as follows Figure 4 .

[0040] To analyze the tunable properties of the metasurface, this embodiment adopts the classical analysis method of metamaterials, assumi...

Embodiment 2

[0053] In this embodiment, on the basis of Embodiment 1, the ring coupler part in the lower circular structure of the small microwave frequency reconfigurable coupler is further optimized.

[0054] On the basis of Embodiment 1, a microstrip stub line is added to the ring coupler. Such as Figure 5 , the center of the microstrip branch line 2 is provided with a microstrip stub line for impedance matching, which is used to improve the degree of freedom of impedance matching. The microstrip stub line is located at the microstrip branch line 2, and all the microstrip stub lines are distributed in one direction, which can be distributed counterclockwise or clockwise at the same time. By setting the microstrip stub line for impedance matching, the standing wave coefficient of the ring coupler is smaller and the energy loss is less.

[0055] Preferably, when the microstrip branch lines 2 are equal, the impedance of the two branch lines is equal, and the matching effect is better. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com