Tea frying roller with multiple frying blades

A drum and stir-frying technology, which is applied in the field of stir-frying tea drums with multiple oars, can solve the problems of uneven quality of fried tea, inability to stir-fry tea evenly, and affect the effect of tea leaves, so as to maintain the aroma and flavor of the wok , Stir-frying effect is better, and the effect of increasing the sticking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

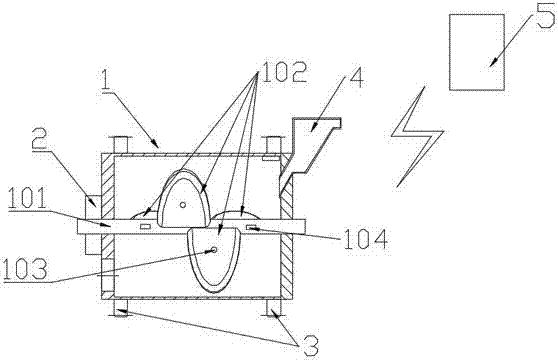

[0029] Such as figure 1 As shown, the present invention provides a multi-paddle stir-fried tea drum, which includes a horizontally placed drum 1, a first driving device 2 and a second driving device 3, and the outside of the right end surface of the drum 1 is provided with a The hopper 4 is provided with the first driving device 2 on the outside of the left end surface, and a rotating shaft 101 is arranged on the axis of the drum 1, and the rotating shaft 101 is connected with the first driving device 2, and the first driving device 2 drives the rotating shaft 101 spins. The drum 1 is driven to rotate by the second drive device 3, the second drive device 3 is a plurality of sets of gear pairs, and the drum 1 is rotated around its axis through gear transmission. The teeth in the figure are 2 groups, They are respectively close to the left and right ends of the drum 1 and located on the outer wall of the drum 1 .

[0030] A plurality of arc-shaped stirrer paddles 102 are alter...

Embodiment 2

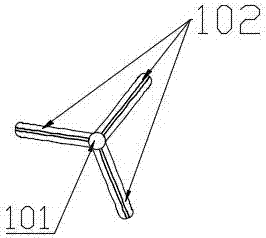

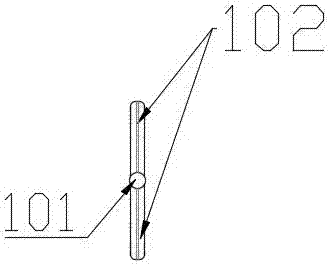

[0035] This embodiment provides a stir-frying drum with multiple paddles, and the included angle between two adjacent stir-frying paddles 102 is 120° or 180°. figure 2 It is an axial schematic diagram with an included angle of 120°. Around the rotating shaft 101 clockwise or counterclockwise, the stir-frying paddles 102 rotate 120° sequentially, that is, there are three stir-frying paddles 102 viewed from the axial direction. image 3 It is an axial schematic diagram with an included angle of 180°, and the stir-frying paddles 102 rotate 180° sequentially, that is, there are two stir-frying paddles 102 on the same plane viewed from the axial direction. The arc edge of the stir-fry paddle 102 is provided with a buffer layer 105, such as Figure 4 , the buffer layer 105 can avoid the increase of broken leaves caused by too much force when the stirrer paddle 102 is in contact with the tea leaves.

Embodiment 3

[0037] Such as Figure 5~6 As shown, in order to better control the humidity in the drum, the end face of the drum provided with the first driving device 2 is also provided with an air outlet device 6 and a fan, and the air outlet device 6 is fixedly connected with the fan. The air outlet device 6 is used to supply air to the tea leaves in the drum 1 to avoid moisture accumulation in the drum 1 ; the air volume of the air outlet device 6 is adjustable and regulated by the integrated control panel 5 . The purpose of setting up the fan is to promote the water evaporation of the tea leaves in the drum 1, and the wind power can be adjusted as required. The fan and the air outlet device 6 are convenient for the tea pot to remove moisture, fully dry, increase the aroma and taste, and make the color of the finished product reach the quality characteristics of gray green and oily; Control fan operation.

[0038] The end face of the drum provided with a hopper is provided with a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com