Integrated device for treating industrial waste gas based on multilayer plate and method for treating industrial waste gas

A technology for industrial waste gas and multi-layer boards, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of damage to the dielectric layer, energy loss, easy breakdown, etc., to avoid corrosion, small wind resistance, and ozone generation. low volume effect

Pending Publication Date: 2017-06-27

ZHEJIANG UNIV

View PDF9 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, the electrode wire tip discharge of the dielectric barrier discharge of this device is easy to break down and damage the dielectric la

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

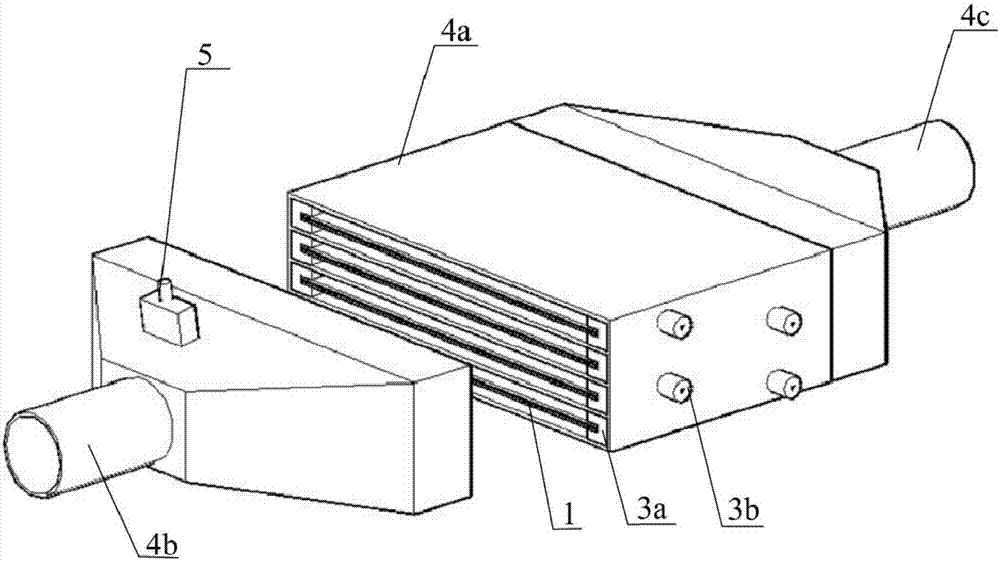

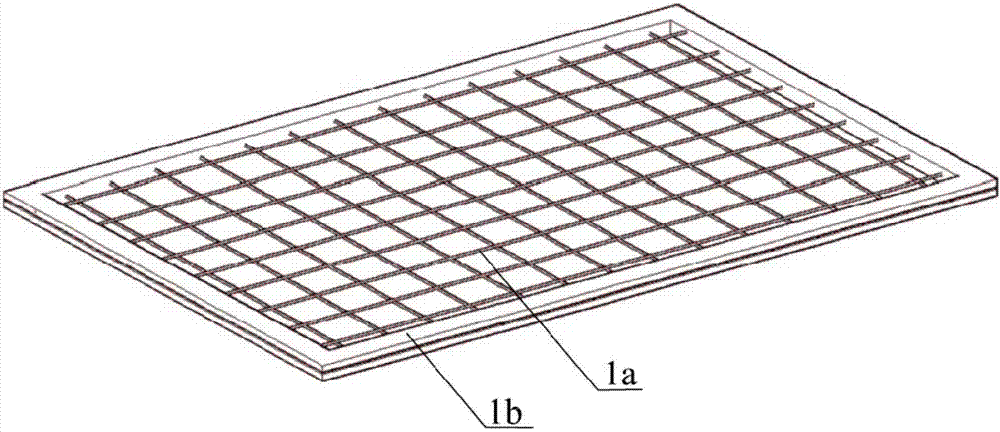

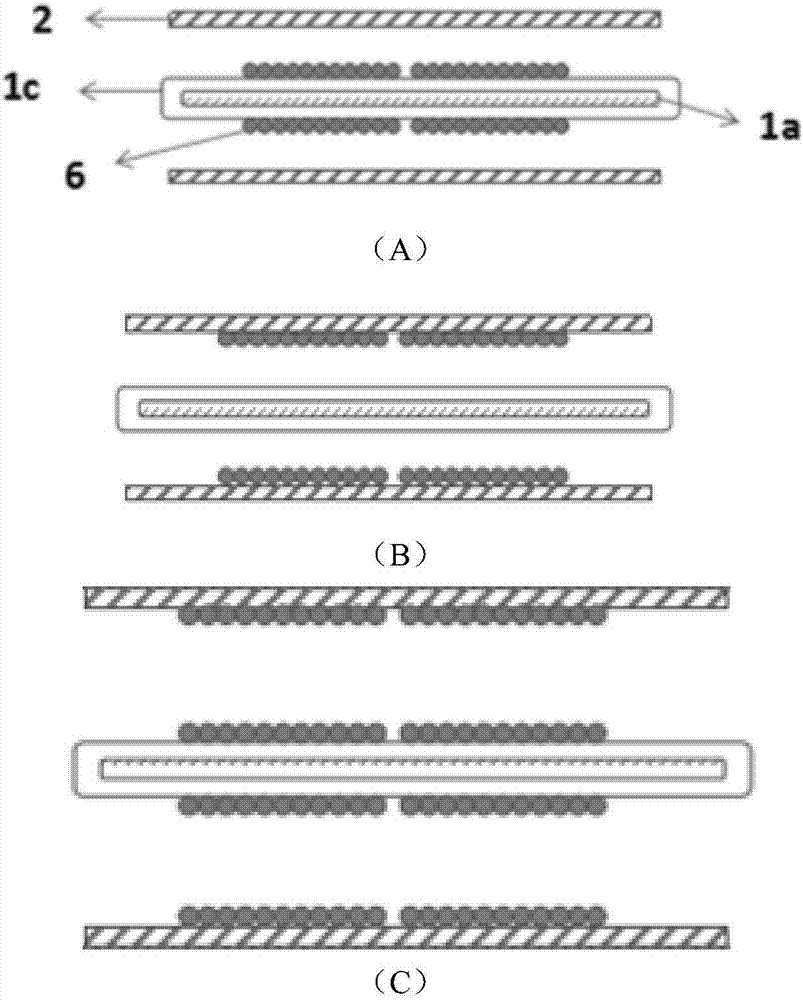

The invention discloses an integrated device for treating industrial waste gas based on a multilayer plate and a method for treating industrial waste gas. The device comprises a casing, an air inlet, an outlet and a multilayer discharge space, wherein the air inlet and the outlet are arranged on the casing; and the multilayer discharge space is disposed in the casing. Each layer of discharge space comprises a grid-shaped high-voltage electrode, dielectric barrier plates arranged on the two sides of the grid-shaped high-voltage electrode and a catalytic material layer arranged between the grid-shaped high-voltage electrode and the dielectric barrier plates. The method for treating industrial waste gas through the integrated device for treating industrial waste gas based on the multilayer plate is adopted. The integrated design method for purification and removal of multiple industrial gaseous pollutants by collaboration of dual dielectric plasma discharge, microwave radiation and catalytic oxidation is implemented.

Description

technical field [0001] The invention relates to the field of industrial waste gas treatment equipment, in particular to a multilayer plate-based integrated device for treating industrial waste gas and a method for treating industrial waste gas. Background technique [0002] Gaseous pollutants emitted by industry are one of the important sources of air pollution, especially the pollution of toxic and odorous gaseous pollutants emitted by the fine chemical industry has become increasingly serious, and it is one of the most typical pollution sources of my country's atmospheric environment. Due to its small footprint and the ability to treat multiple pollutants at the same time, low-temperature plasma technology has been applied in the field of environmental governance since the 1980s. It is one of the frontier topics currently used to deal with VOCs (volatile organic compounds) research. One, it is attracting more and more attention. [0003] Low-temperature plasma technology ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/86B01D53/72B01D53/48B01D53/52B01D53/58B01D53/54

CPCB01D53/8606B01D53/8612B01D53/8621B01D53/8634B01D53/8668B01D2259/806B01D2259/818B01D2257/7027B01D2257/70B01D2258/02

Inventor 王向前李伟徐佩伦任翔宇

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com