Sealant coating device and self-cleaning method

A gluing device and self-cleaning technology, applied in the directions of cleaning methods and utensils, cleaning methods using gas flow, spraying devices, etc., can solve problems such as troublesome cleaning work, difficulty in cleaning glue materials, uneven gluing, etc., to avoid problems such as Affect follow-up operations and equipment safety, reduce cleaning workload, and avoid the effect of plastic blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

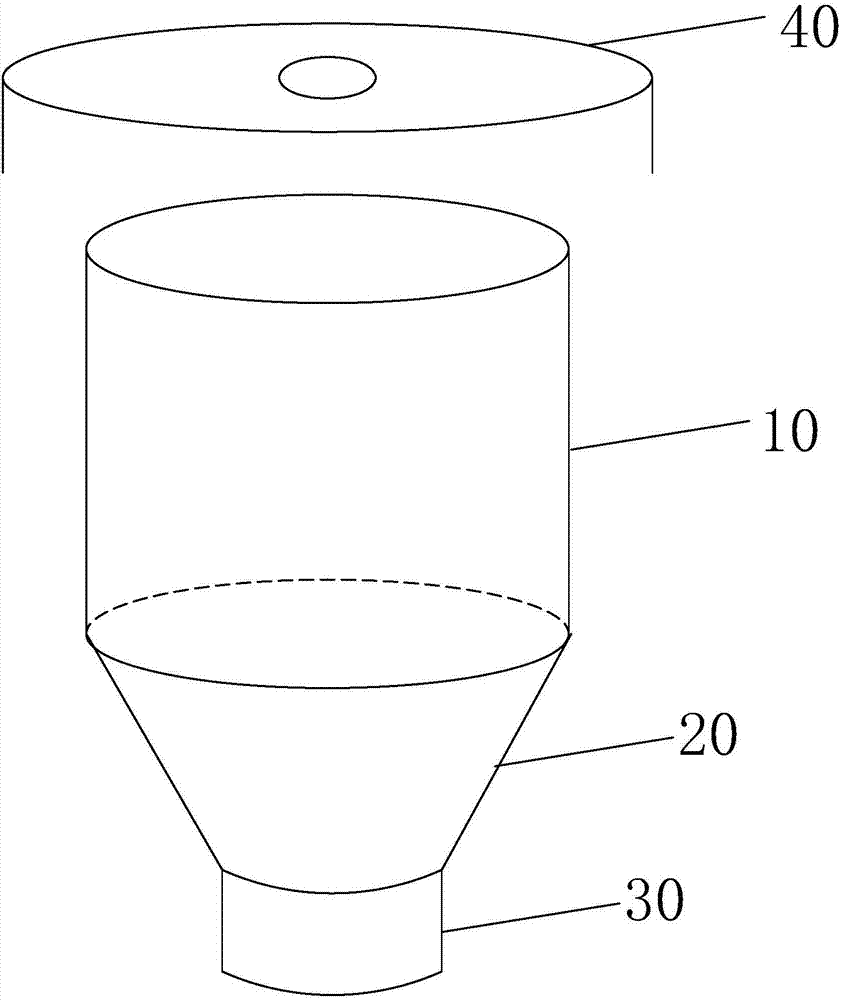

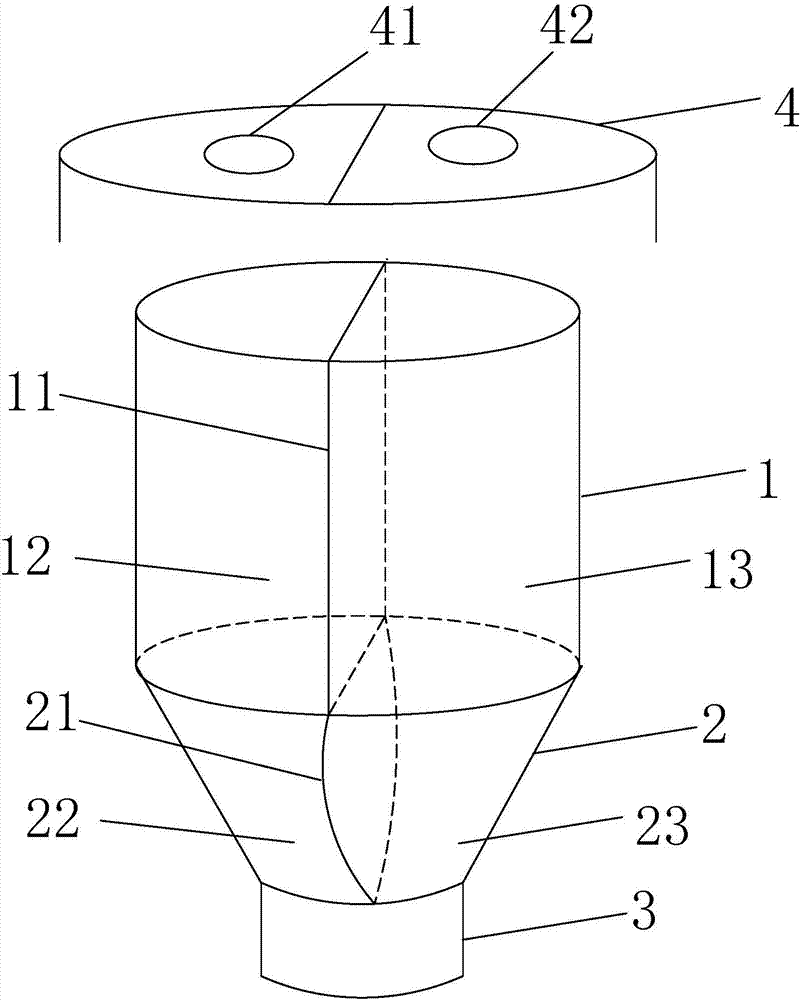

[0031] Please also see Figure 2 to Figure 5 , the present invention firstly provides a kind of gluing device, comprises: glue pipeline 1, the gluing pipeline 2 that is connected with described gluing pipeline 1, the gluing nozzle 3 that is connected with described gluing pipeline 2, and cover is arranged on The gas control unit 4 above the glue pipeline 1 .

[0032] The glue pipeline 1 is provided with a fixed partition 11, and the fixed partition 11 separates the glue pipeline 1 into a glue storage pipeline 12 and a first gas pipeline 13;

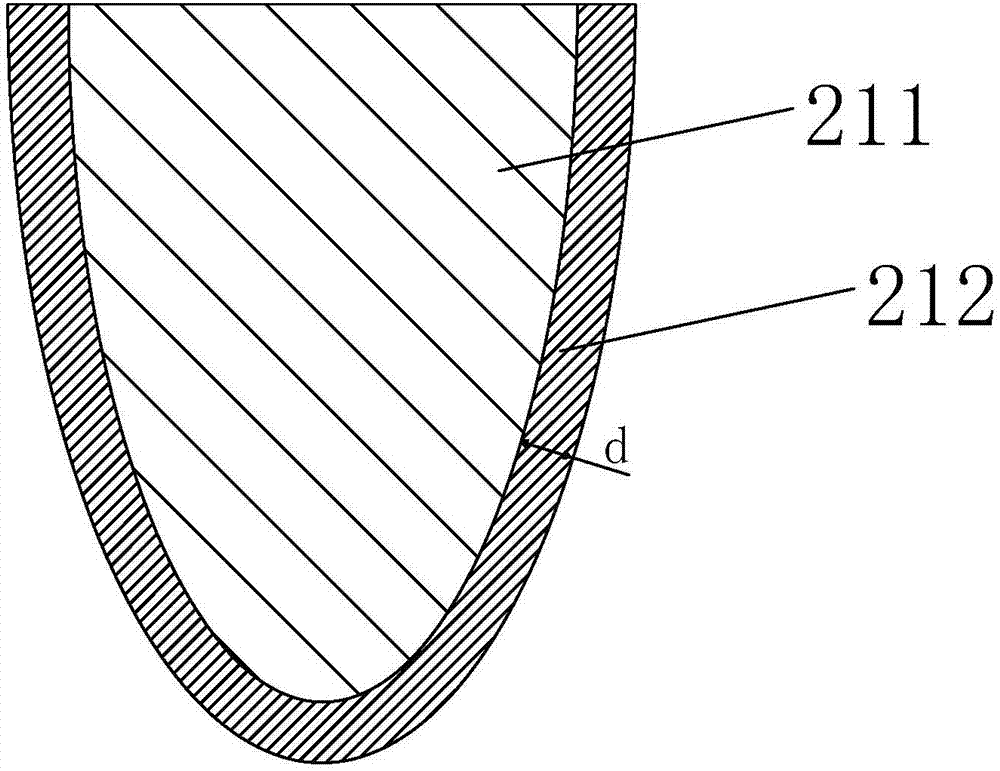

[0033] A movable baffle 21 is arranged in the glue-coating pipeline 2, and the movable baffle 21 separates the glue-coating pipeline 2 into a glue circulation pipeline 22 and a second gas pipeline 23;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com