Waterproof joint structure of steel structure workshop

A steel structure and node technology, applied in building structures, building components, roof insulation materials, etc., can solve the problems of undisclosed rainwater leakage prevention, poor flooding effect, hidden water leakage, etc., and achieve optimized and fixed flooding effect. The method is firm and stable, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

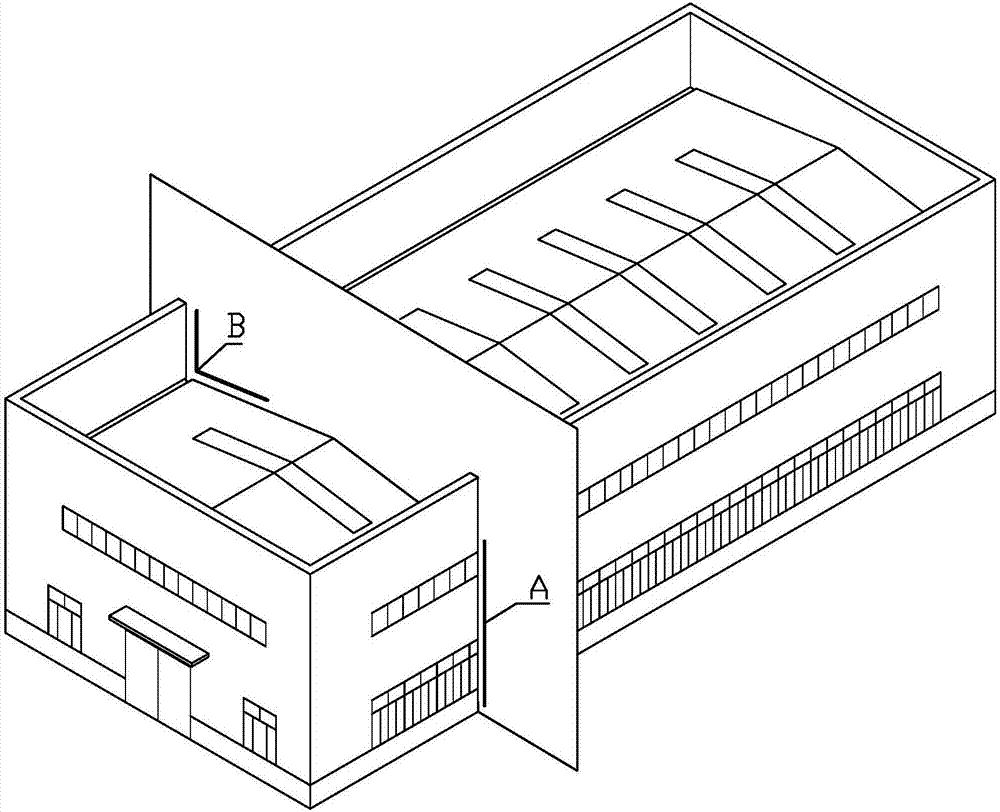

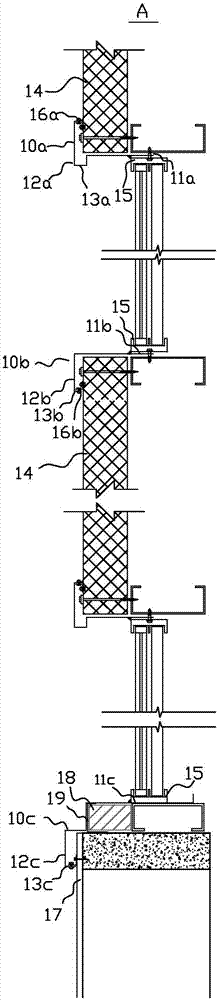

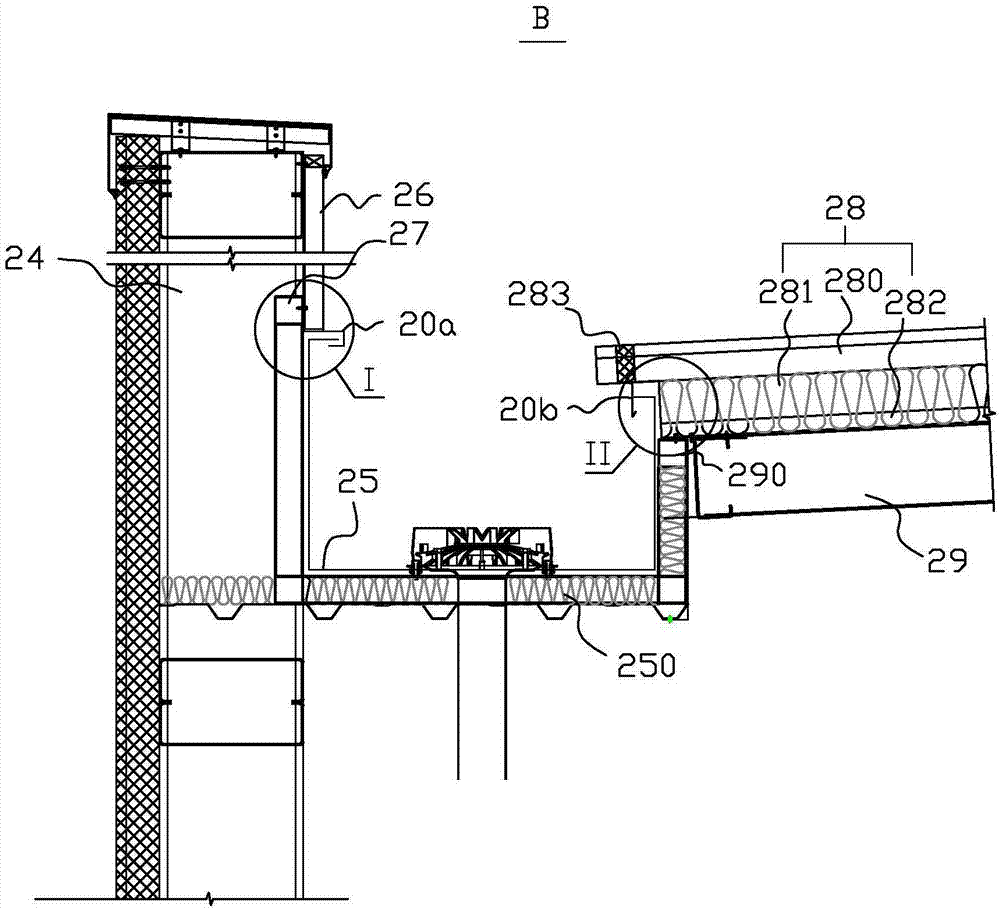

[0021] A waterproof node structure of a steel structure factory building according to the present invention shows the nodes including the steel roof and the vertical and horizontal spans of the rigid wall, such as figure 1 Shown is an embodiment of the steel structure workshop of the present invention, figure 1 The dashed line A is the node structure at the vertical and horizontal spans of the steel roof, and the dashed line B is the node structure of the rigid wall. In this embodiment, the node structure includes a flashing structure, and the flashing structure at least includes a flashing part 12a, 12b, 12c, 22a, 22b and at least one fixing part 11a, 11b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com