Anti-freezing and anti-cracking concrete

A technology of concrete and antifreeze, which is applied in the field of building materials, can solve the problems that concrete cannot meet the requirements, and achieve the effects of increased strength, good toughness and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

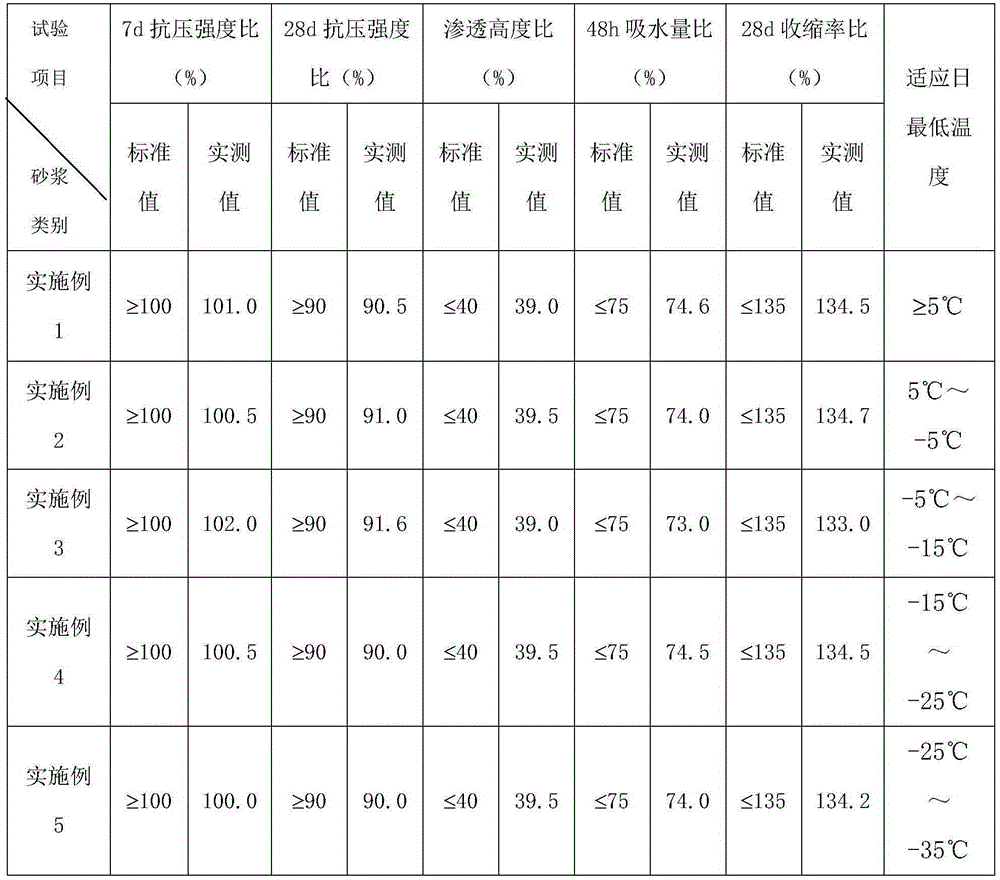

Examples

Embodiment 1

[0018] A kind of antifreeze and anti-crack concrete, suitable for daily minimum temperature: ≥ 5°C, component formula: cement 10.0%, sand 30.0%, gravel 42.0%, water 15.0%, admixture 2.0%, waterproof agent 1.0%, antifreeze agent 0.0% .

[0019] Among them, the cement is ordinary Portland cement, grade 32.5;

[0020] The admixture is a high-performance composite admixture, which is prepared by water reducing agent, expansion agent, cellulose ether, boric acid, aluminum powder, and sodium silicate in a weight ratio of 1:1:1:1:1:1; wherein , the water reducer is one of aliphatic powder water reducer, naphthalene powder water reducer, or polyhydroxy acid powder water reducer; the expansion agent is one of calcium oxide expansion agent, alum expansion agent and iron filings expansion agent ; Cellulose ether is a kind of methyl cellulose, hydroxypropyl methyl cellulose, ethyl cellulose, hydroxyethyl cellulose;

[0021] The waterproofing agent is a silicone-based waterproofing agent...

Embodiment 2

[0027] A kind of antifreeze and anti-crack concrete, suitable for daily minimum temperature: 5℃~-5℃, component formula: cement 12.0%, sand 28.0%, gravel 41.0%, water 14.0%, admixture 2.8%, waterproofing agent 1.2%, antifreeze agent 1.0%.

[0028] Among them, the cement is fly ash portland cement, grade 32.5;

[0029] The admixture is a high-performance composite admixture, which is prepared by water reducing agent, expansion agent, cellulose ether, boric acid, aluminum powder, and sodium silicate in a weight ratio of 1:1:1:1:1:1; wherein , the water reducer is one of aliphatic powder water reducer, naphthalene powder water reducer, or polyhydroxy acid powder water reducer; the expansion agent is one of calcium oxide expansion agent, alum expansion agent and iron filings expansion agent ; Cellulose ether is a kind of methyl cellulose, hydroxypropyl methyl cellulose, ethyl cellulose, hydroxyethyl cellulose;

[0030] The waterproofing agent is a high-grade fatty acid waterproof...

Embodiment 3

[0037] A kind of antifreeze and anti-crack concrete, suitable for daily minimum temperature: -5℃~-15℃, component formula: cement 13.0%, sand 28.0%, gravel 39.7%, water 14.0%, admixture 3.0%, waterproofing agent 1.2%, Antifreeze 1.1%.

[0038] Among them, the cement is fly ash portland cement, grade 42.5;

[0039] The admixture is a high-performance composite admixture, which is prepared by water reducing agent, expansion agent, cellulose ether, boric acid, aluminum powder, and sodium silicate in a ratio of 1:1:1:1:1:1; wherein, The water reducer is one of aliphatic powder water reducer, naphthalene powder water reducer, or polyhydroxy acid powder water reducer; the expansion agent is one of calcium oxide expansion agent, alum expansion agent and iron filings expansion agent; Cellulose ether is a kind of methyl cellulose, hydroxypropyl methyl cellulose, ethyl cellulose, hydroxyethyl cellulose;

[0040] The waterproofing agent is a high-grade fatty acid waterproofing agent;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com