Monitoring device and method for hydrate deposition law in deepwater gas well testing period

A monitoring device and hydrate technology, which are applied in the directions of surveying, earth-moving drilling and production, wellbore/well components, etc., can solve the problem of different thicknesses of hydrate layers and cannot effectively measure the deposition thickness of hydrate layers. The hydrate deposition law, thickness and law Issues such as insufficient research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

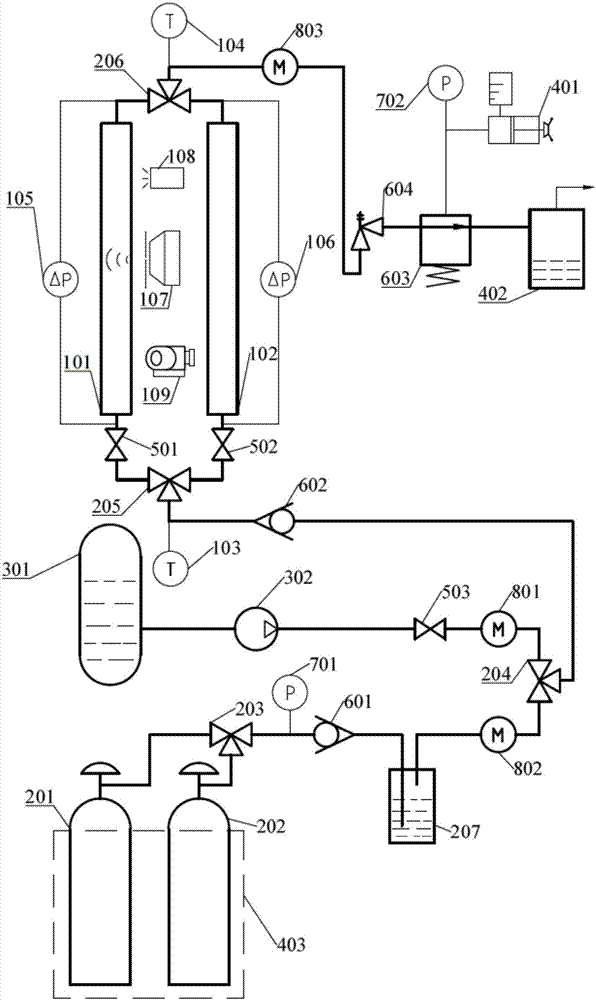

[0021] figure 1 As shown in Fig. 1, the monitoring device for the regularity of hydrate deposition during deep-water gas well testing includes: gas-liquid delivery system, hydrate monitoring system, and auxiliary system; the gas-liquid delivery system provides gas source and liquid source, which are mixed and delivered to the hydrate monitoring system; The hydrate monitoring system forms hydrates in the simulated wellbore under high pressure and low temperature conditions, records and observes the process of hydrate crystallization, deposition and clogging; the auxiliary system performs gas post-processing and realizes the safety control of the device.

[0022] Gas-liquid delivery system, including: cooling water bath 403, first gas cylinder 201, second gas cylinder 202, first three-way valve 203, first pressure sensor 701, first one-way valve 601, first container 207, water storage Tank 301, booster pump 302, third stop valve 503, first mass flow meter 801, second mass flow m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com